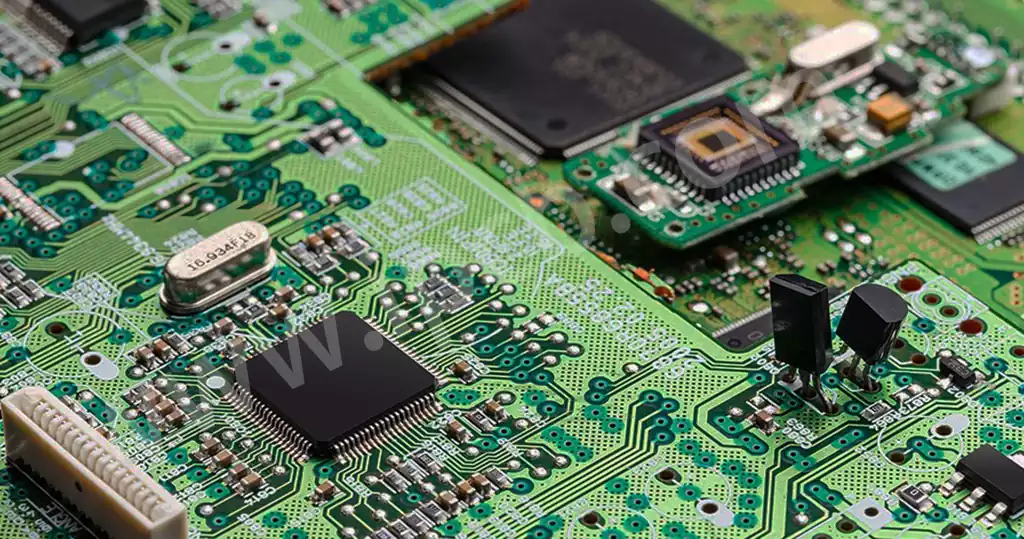

The definition of PCBA contaminants refers to any surface deposits, impurities, inclusions, or adsorbed substances that reduce the chemical, physical, or electrical performance of the PCBA to an unacceptable level. The main aspects include the following:

- Contamination or oxidation of the components and PCB itself can lead to surface contamination of the PCBA board;

- Residues generated by flux during the manufacturing process are also major contaminants;

- Fingerprints, chain claw marks, fixture marks, and other types of contaminants generated during the soldering process, such as hole-blocking adhesive, high-temperature tape, handprints, and dust;

- Contamination caused by dust, water, solvent vapours, smoke, small organic particles, and electrically charged particles adhering to the PCBA due to static electricity in the workplace.

Classification of PCBA Contaminants

- Polar Contaminants

Polar contaminants, also known as inorganic contaminants or ionic residues, primarily include active substances in flux, such as halide ions, acid anions, and metal ions generated by corrosion. These contaminants can form conductive paths in humid environments, leading to circuit shorts or corrosion, severely affecting the performance and lifespan of electronic products. - Non-polar contaminants

Non-polar contaminants, also known as organic contaminants or non-ionic contaminants, primarily include organic components in flux, flux residues, oils, dust, etc. Although these contaminants do not directly participate in electrochemical reactions, they can obstruct heat dissipation, reduce insulation performance, and to some extent affect the appearance and performance of electronic products. - Particulate contaminants

Particulate contaminants primarily include solder dross, solder balls, and loose metal particles. These contaminants may cause short circuits or mechanical damage on circuit boards, particularly in high-density PCBA assemblies, where their hazards are more pronounced.

Typical PCBA cleaning processes

Solvent Cleaning

- ODS-based, hydrocarbon-based, alcohol-based, ketone-based, fluorinated solvents, and mixed solvents such as azeotropes and co-solvents;

- Solvent characteristics include flammability, explosiveness, environmental damage, and harm to human health.

Semi-Aqueous Solutions

- Organic solvent cleaning followed by water rinsing;

- Most organic solvents have certain flammability and volatility.

Water-based cleaning

- Water-based cleaning + water rinsing

PCB ion cleanliness testing methods

- Anion-cation testing method Anion-cation testing analyses contamination levels based on the types and concentrations of anions, cations, and organic acids. The advantage of this method is that it provides detailed insights into the sources of contaminants, the types of residual ions, and their concentrations.

- Sodium Chloride Equivalent Method The sodium chloride equivalent method uses ultra-pure extraction solutions to remove residual substances left on electronic components during the manufacturing process. Cleanliness results are measured based on conductivity or resistivity. The disadvantage of this method compared to the anion-cation method is that it cannot clearly identify the types and concentrations of ionic contaminants.

Sample requirements: To ensure the accuracy of test results, samples generally require a surface area greater than 100 cm². Samples must be sealed during shipment to prevent secondary contamination.

PCBA contaminants, as key factors affecting the performance and lifespan of electronic products, have diverse sources and types, posing a potential threat to the stable operation of electronic products. Meanwhile, PCB ion cleanliness testing methods provide an effective means to assess the cleanliness of PCBA, helping to ensure the quality and reliability of electronic products.