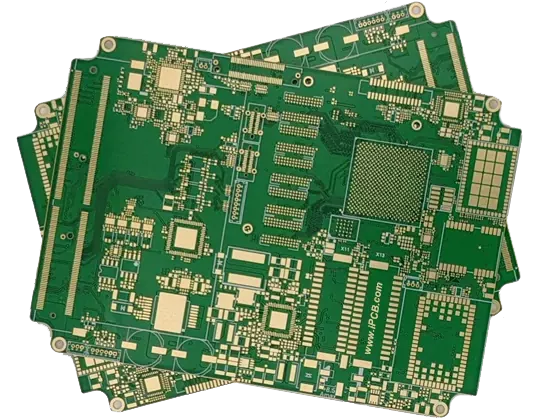

What does FPC stand for? FPC stands for Flexible Printed Circuit, known in Chinese as a flexible printed circuit board, commonly abbreviated as a flexible board. FPC is a highly reliable, exceptionally flexible printed circuit board manufactured using polyimide or polyester film as the substrate material, also referred to as a flexible circuit board or flexible printed circuit. They are categorised into four types: single-sided, double-sided, multilayer, and rigid-flex boards. They are characterised by high wiring density, light weight, thin profile, and excellent bendability.

Within mobile phones, FPC is applied across components including batteries, screens, cameras, side buttons, antennas, fingerprint modules, and speakers. Since the penetration of 5G communication technology, the number of internal phone components has increased, with the addition of 5G antennas further driving growth in internal FPC usage. Since the commercialisation of 5G, mobile phone flex board usage has risen by 15%-20%, while the area of mainboards has also expanded concurrently.

Within the smartphone camera assembly, FPC serves as the circuit connection for the CMOS sensor. One end of the Flex pcb connects to the gold wires of the CMOS sensor, while the other end links to the mainboard, thereby completing the electrical circuit. The camera’s ability to capture images and generate photos relies entirely on FPC support. Within the smartphone camera, FPC fulfils the following functions: 1. Provides electrical properties, acting as an electrical connection; 2. Delivering mechanical properties to support the fixation and assembly of electronic components; 3. Enabling automated placement, soldering, and inspection between integrated circuits and electronic components.

The evolution from dual-camera to multi-camera rear setups in smartphones signifies a technological revolution in camera systems. This advancement not only fulfils users’ demands for high-quality, diverse photography capabilities, achieving more vivid and natural imaging effects, but has also become a focal point for differentiation among smartphone manufacturers. Under the 5G network infrastructure, the proliferation of multi-camera systems in mobile phones will drive increased demand for Flexible Printed Circuits. During production, mobile camera flexible pcb must undergo testing to verify both performance compliance and the absence of quality defects.

Within mobile phone cameras, FPC serves the following functions:

- Providing electrical properties to facilitate electrical connections;

- Offering mechanical performance to support the fixation and assembly of electronic components;

- Enabling automated placement, soldering, and inspection between integrated circuits and electronic components.

Among the testing components required for mobile phone camera FPC testing, the spring-loaded micro-needle module is indispensable. Its slim, spring-loaded design adapts to complex internal circuitry and minute spacing within mobile phones, accommodating pitch values between 0.15mm and 0.4mm. It maintains long-term connectivity without pin jamming or needle breakage, delivering superior performance. During electrical connection of mobile camera FPCs, the spring-loaded micro-needle module transmits currents ranging from 1 to 50A with stable overcurrent performance and no current attenuation. It offers reliable connectivity and an average lifespan exceeding 200,000 cycles, eliminating frequent replacement and significantly enhancing testing efficiency for mobile camera FPCs.

With technological advancement, inherent limitations in the physical properties and manufacturing processes of flexible printed circuits have become apparent. Demands for increasingly miniaturised products and finer circuit lines pose significant challenges to current fabrication techniques.

Additionally, growing global concern over environmental pollution—including but not limited to copper-rich solutions generated during the etching stage of FPC production and waste residues from soldering and electroplating—has heightened pollution treatment costs while causing severe ecological damage.

Moreover, the intricate processing steps result in generally low production efficiency for flexible circuit boards. Coupled with rising labour costs, this further intensifies operational pressures for enterprises. The FPC industry eagerly anticipates the emergence of new processes to resolve these existing issues.

As a critical internal connectivity component within mobile phones, flexible printed circuits (FPC) play an increasingly vital role in the 5G era. With the proliferation of 5G technology and multi-camera configurations, demand for FPC continues to grow. The testing application of spring-loaded micro-needle modules effectively ensures their performance and quality.