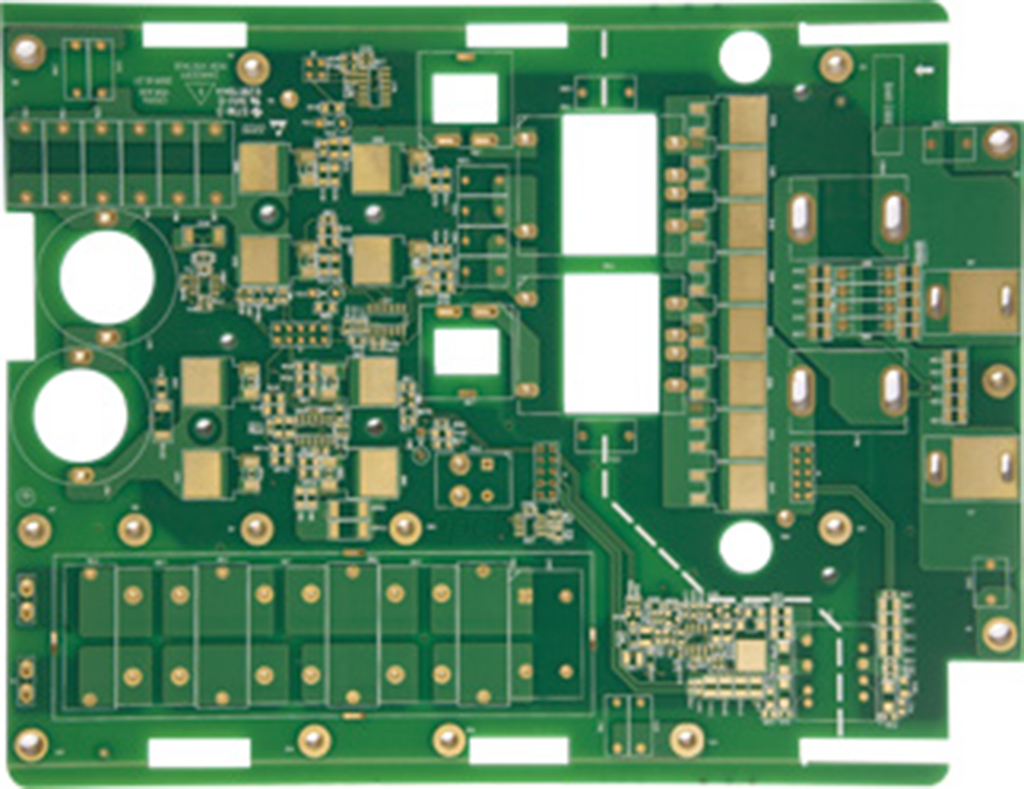

Bridging is one of the common defects in PCBA processing, particularly during the SMT placement process. The occurrence of bridging issues often severely impacts product quality and reliability. Bridging can lead to circuit short-circuits, signal interference, and even cause product functional failure.

Causes of bridging:

PCB design flaws: When large or heavy components are concentrated on one side of the PCB board, uneven weight distribution may cause warping, potentially triggering bridging.

Incorrect component orientation: Incorrect placement direction of components can also induce bridging.

Insufficient spacer clearance: Inadequate clearance between spacers may permit bridging during assembly.

Improper reflow oven temperature profile: Unoptimised temperature profiles adversely affect soldering quality, potentially causing bridging.

Unsuitable placement pressure settings: Placement pressure is critical during assembly; improper settings may similarly induce bridging.

Potential consequences of bridging:

Circuit short-circuiting: Solder flow creates a short between two pads, potentially causing circuit malfunction.

Signal interference: Bridging may alter circuit impedance, disrupting signal transmission and compromising device performance.

Product failure: Severe bridging can prevent product startup or cause operational faults, affecting functionality and stability.

Impact of bridging on production and quality

Bridging not only disrupts circuit functionality but also incurs additional production costs. Specific impacts include:

Increased rework expenses: Bridging necessitates product rework and repair, elevating production costs and timeframes.

Diminished product quality: Recurring bridging issues compromise product quality, damaging corporate brand reputation and market competitiveness.

Reduced production efficiency: Bridging incidents frequently cause production line stoppages, hindering timely delivery and undermining overall manufacturing productivity.

Technical Principles of Bridging

Flow Characteristics of Solder Paste

The flowability of solder paste is one of the key factors contributing to bridging. During the reflow soldering process, solder paste melts under the influence of temperature, causing the solder to begin flowing. If the solder paste exhibits excessive flowability, particularly under high-temperature conditions, it may cause the solder to spread excessively into unintended areas, ultimately resulting in bridging. Furthermore, characteristics such as the paste’s viscosity, adhesion, and wettability all influence solder flow behaviour, thereby affecting the likelihood of bridging.

The Role of Temperature in Solder Flow

The distribution of soldering temperatures plays a decisive role in bridging occurrence. An improperly configured temperature profile within the reflow oven can cause excessive solder paste flow. Particularly in areas experiencing elevated temperatures during soldering, heightened solder activity can readily trigger uncontrolled flow, substantially increasing bridging probability.

Influence of PCB Design and Pad Layout

PCB design, especially pad layout, significantly impacts bridging issues. Inadequate pad spacing or improper pad dimensions during design can cause uneven solder flow during soldering, leading to bridging. Therefore, scientifically sound pad layout and appropriate spacing design form the fundamental prerequisites for preventing bridging.

The Role of Component Placement and Orientation

Within the SMT manufacturing process, the correct placement and orientation of components also influence bridging during soldering. Incorrect or asymmetrical component placement can cause uneven solder flow during soldering, thereby triggering bridging.

Methods to Prevent Bridging:

- Enhancing Anti-Bridging Measures in SMT Assembly

Boosting Flux Efficacy: Select highly reactive flux to enhance solder wetting and reduce bridging risks.

Precise Temperature Control: Accurately regulate solder temperature to ensure soldering quality and prevent bridging.

Optimised Preheating: Increase PCB preheating temperature to improve pad wettability and minimise bridging.

Selecting premium materials: Employing PCB board and components with excellent solderability reduces bridging risks at source.

Maintaining a clean environment: Preserving a pristine workspace minimises impurity contamination and prevents bridging.

- Solutions for soldering issues

Optimising PCB component layout: Avoiding excessive weight concentration on one side ensures PCB balance.

Verifying component placement orientation: Ensuring accuracy.

Optimise spacer spacing: Ensure adequate clearance between spacers to prevent bridging during assembly.

Scientifically set reflow oven temperature profiles: Precise programming is essential, directly impacting soldering quality.

Appropriately configure placement pressure: Proper pressure settings are critical; improper pressure may cause soldering defects or bridging.

- PCB Design Phase Planning: This encompasses scientifically setting temperature profiles and rationally planning component layout.

- Selecting an appropriate solder paste printer: This helps minimise issues with poor solder paste coverage.

- Precise control of solder paste volume: Rationally regulating solder paste coverage reduces problems caused by excessive paste, such as collapse and excessive flow.

- Scientific solder mask configuration: Correctly setting the solder mask is crucial for mitigating solder bridging risks.

Bridging issues in PCBA processing carry significant implications, involving multiple process factors. Implementing measures such as enhancing flux efficacy and precise temperature control can effectively prevent and resolve bridging, thereby improving product quality and production efficiency while strengthening corporate competitiveness.