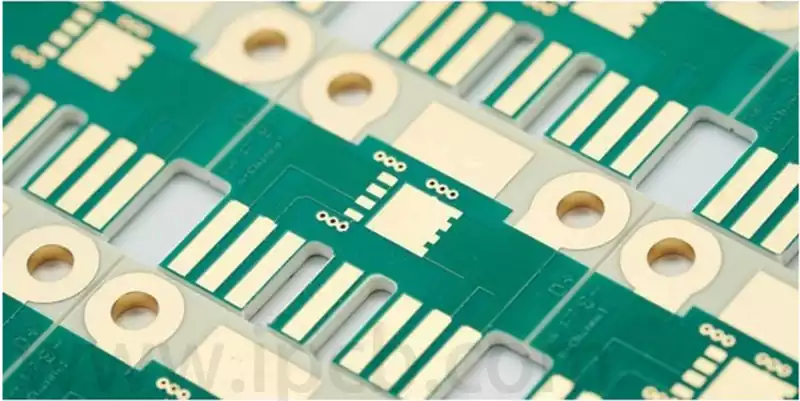

Rogers ceramic pcb is a kind of circuit board using ceramic material as the substrate, which has the advantages of high thermal conductivity, high insulation, corrosion resistance and high temperature resistance. This type of circuit board is suitable for use in a variety of electronic products that require high performance and reliability, such as aerospace, medical equipment, industrial control and other fields.

The features of Rogers ceramic pcb is as follows:

High thermal conductivity: ceramic materials have high thermal conductivity, which can quickly transfer heat and ensure stable operation and long life of electronic components.

High insulation: Ceramic material has high insulation, which can ensure the safety and stability of the circuit board.

Corrosion and temperature resistance: Ceramic materials are corrosion and temperature resistant and can be used for a long time under harsh environmental conditions.

High reliability: Rogers ceramic pcb undergo rigorous manufacturing processes and testing procedures, which can provide a high degree of reliability and stability, ensuring the long-term use and stability of electronic products.

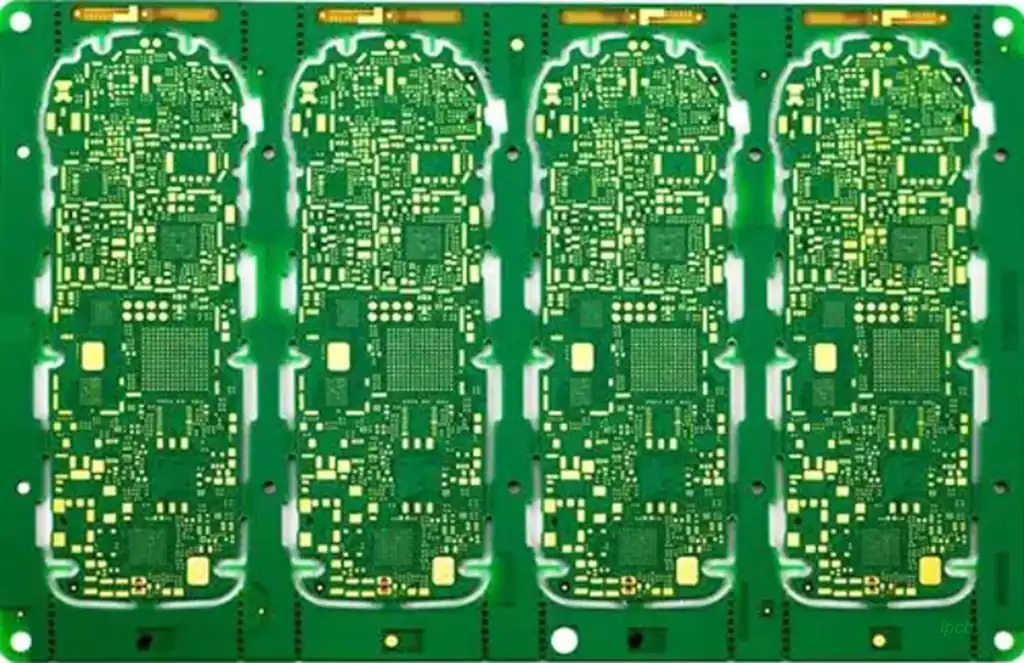

Production: Rogers ceramic pcb can be adjusted according to customer needs, including the number of layers, materials, circuit wiring and other aspects to meet the needs of different application scenarios. It can better meet the special needs of customers and improve the competitiveness and adaptability of products.

Rogers ceramic pcb is usually made of ceramic materials with high thermal conductivity and excellent electrical insulation, such as alumina (Al2O3), aluminium nitride (AlN) and silicon nitride (Si3N4) powders.

Ceramic substrate preparation

Rogers ceramic substrates are mainly made of alumina (Al2O3), aluminium nitride (AlN) and silicon nitride (Si3N4) with high thermal conductivity and excellent insulating properties, which ensure the stability and durability of the circuit boards in high power density and harsh environments.

Raw material selection: High purity ceramic powders are used to ensure substrate density and thermal conductivity.

Forming and pre-firing: Ceramic powder is moulded and pressed to form a preliminary substrate, which is pre-fired to remove moisture and organic impurities.

High-temperature sintering: The substrate is sintered at a high temperature of over 1200°C to bond the ceramic particles and achieve mechanical strength and thermal performance targets.

Slow Cooling Process: The cooling rate is controlled to prevent substrate cracks and stress concentrations and maintain structural integrity.

The metallisation layer is the most central part of Rogers ceramic pcb, involving the bonding technology of copper to the ceramic substrate to ensure circuit conductivity and heat dissipation functions.

- Direct Bonded Copper Process (DBC)

Principle: Under high temperature eutectic conditions at 1065°C, copper foil is bonded directly to the ceramic substrate to achieve a high integrity bonding surface through the formation of mechanical and chemical bonding layers between copper and ceramic.

Process:

Ceramic substrate and copper foil are subjected to surface cleaning and oxide film removal respectively.

The copper foil is pre-treated, including degreasing and activation.

Place in a high temperature furnace and heat according to the temperature profile to achieve strong bonding of aluminium oxide and copper.

Cool to room temperature to complete the finished substrate production.

Features:

Strong bonding, able to withstand heavy duty thermal cycling.

High thermal conductivity, suitable for power semiconductor packaging.

Good CTE matching, reduce thermal stress, enhance product life.

- Activated metal brazing process (AMB)

The brazed connection of the copper layer to the aluminium nitride substrate is achieved at high temperatures (around 800°C) using an activated brazing material.

The use of an intermediate metal layer activates the ceramic surface and improves the bond strength.

The brazed joints conduct heat well and are suitable for heat dissipation substrates for precision electronic components in high heat load environments.

- Direct copper plating process (DPC)

It is a low-temperature, solderless process, suitable for manufacturing high-precision microfabricated circuits.

A titanium/copper film is deposited as a seed layer by vacuum sputtering technology.

The lines are defined using photolithography and the thickness of the copper lines is built up by chemical plating and electroplating.

Suitable for RF and antenna high-frequency circuit boards, compatible with sensitive substrates due to process temperatures below 300°C.

After substrate metallisation, fine circuit patterning is required to ensure circuit performance and reliability.

Photolithographic patterning:

A light-sensitive photoresist is coated on the copper surface.

A photomask is exposed to form the desired circuit pattern.

Developing reveals the uncovered portion.

Etching the copper layer:

A chemical solution is used to etch away unwanted copper, leaving the design lines intact.

Multi-layer circuits are also etched with internal wiring, with layers connected through vias.

Plating Thickening:

A copper layer is plated on the circuit to ensure adequate conductivity and durability.

Solderability and oxidation resistance are improved by metal finishes such as gold immersion.

Inspection & Testing:

Optical inspection (AOI) to check circuit integrity.

Electrical testing ensures that the circuit is normal and free of short and open circuits.

Strict process control ensures a reliable finished product.

Rogers ceramic pcb, with their superior material properties and advanced manufacturing processes, significantly improve the performance and reliability of electronic products at high temperatures, high power densities and in complex environments. As technology continues to advance, Rogers ceramic pcb will plays a key role in more high-end applications, helping electronic products continue to innovate and upgrade.