What is a protoboard?

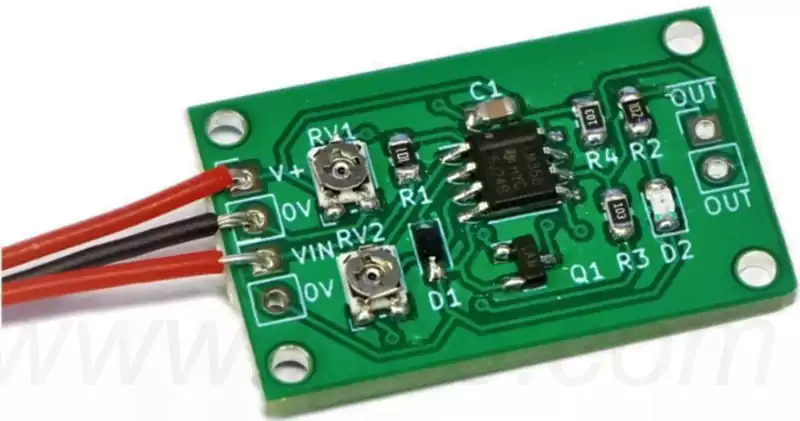

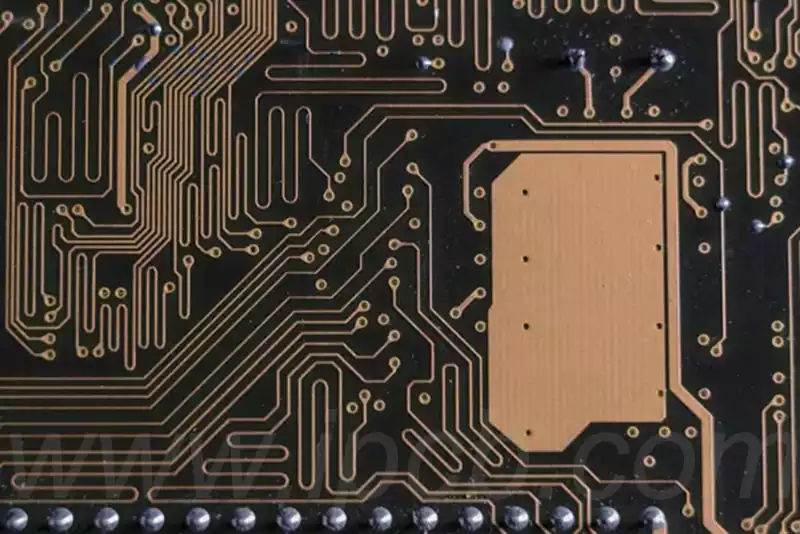

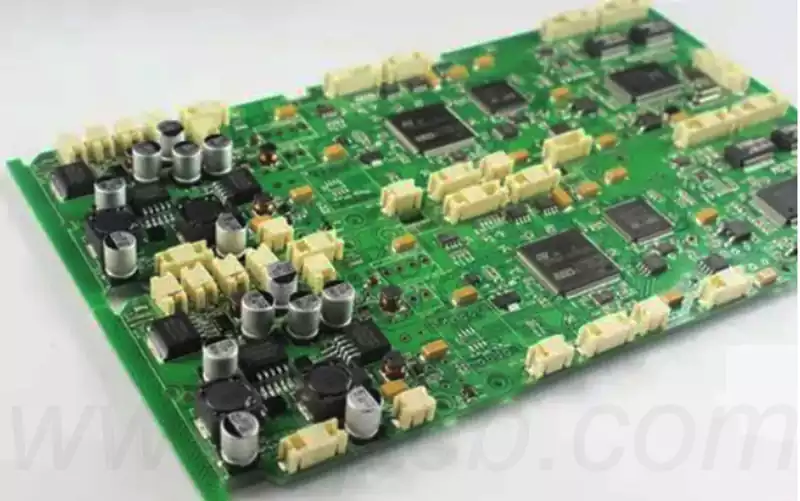

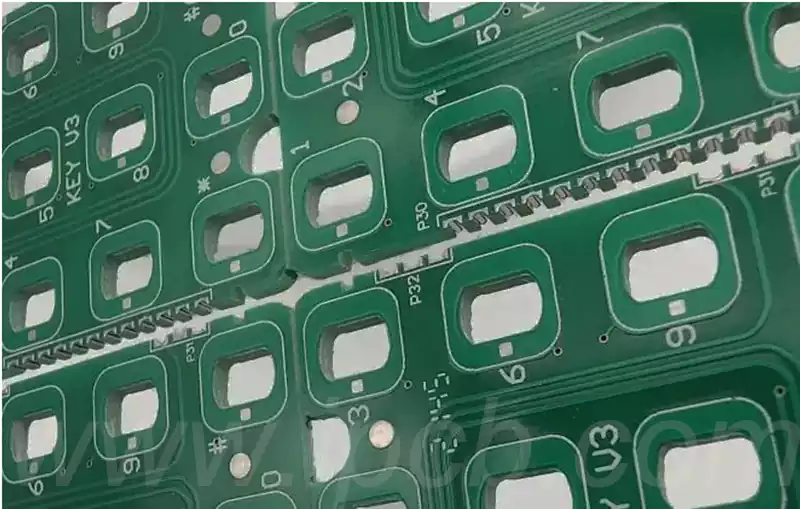

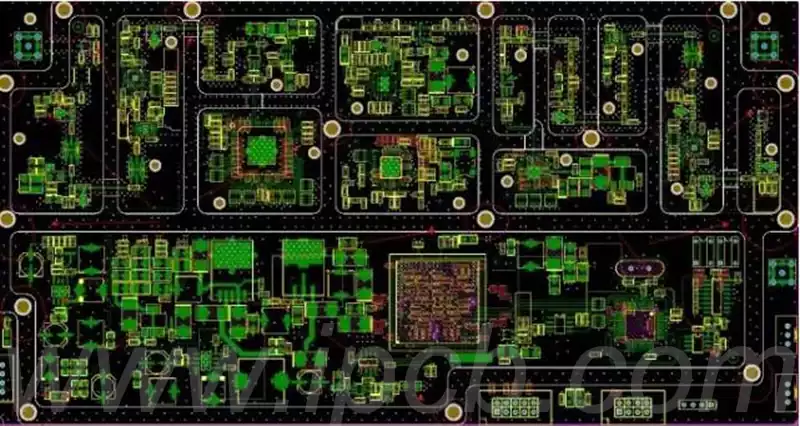

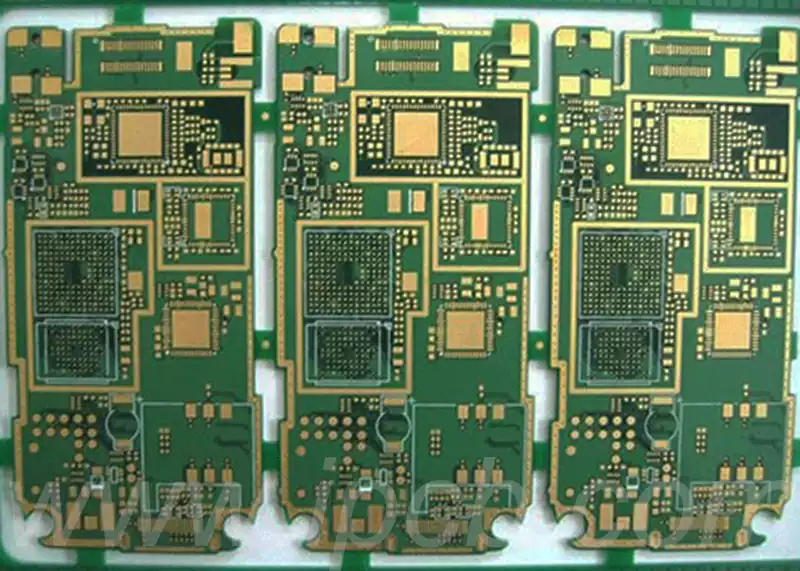

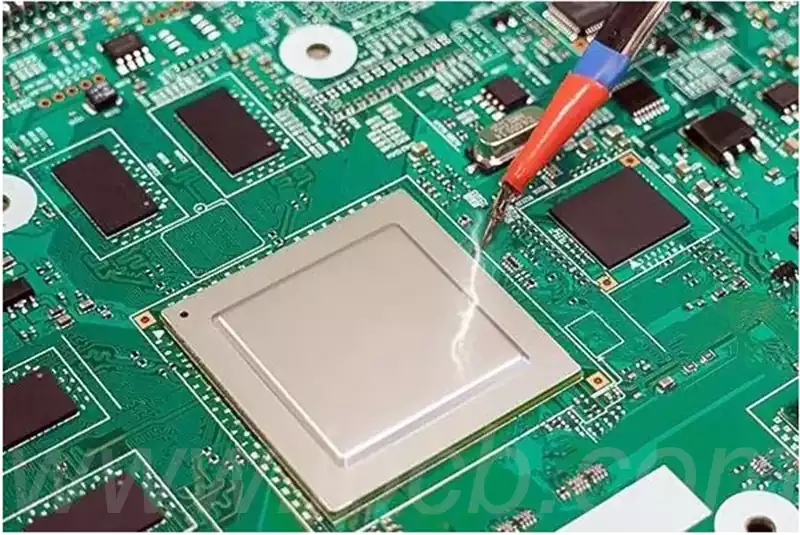

What is a protoboard?A protoboard, also known as a ProtoType board, is essentially an early sample of a product that is designed to test a design idea and see if it works. While most prototypes are made just to test basic user functionality, PCB prototypes need to be functional in some way, as they are […]