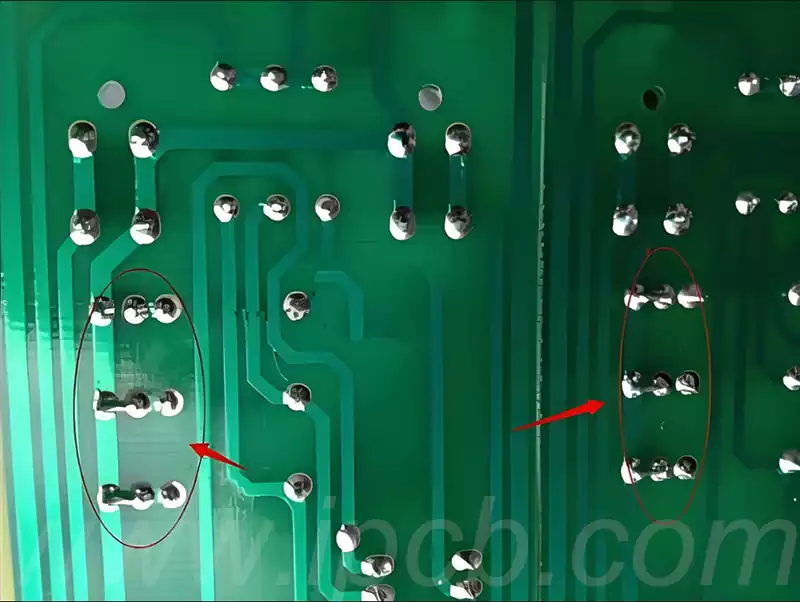

PCB solder pad came off Guide

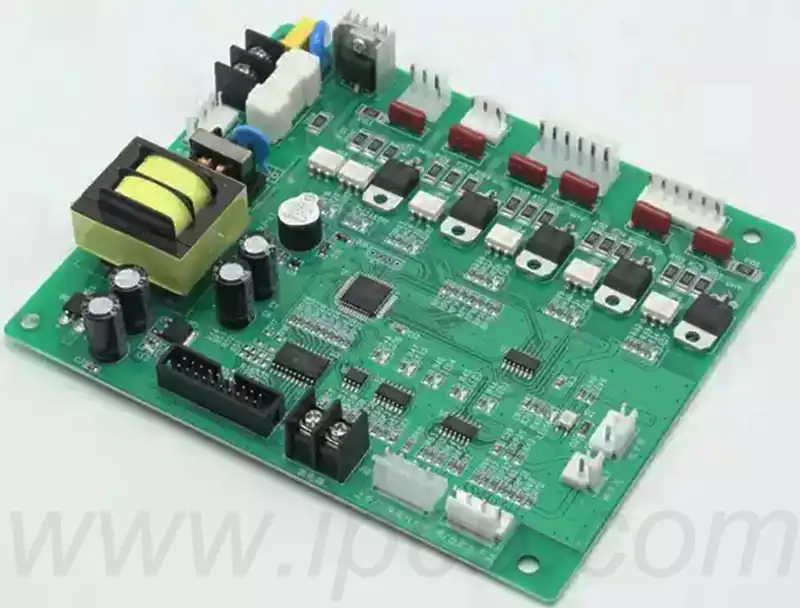

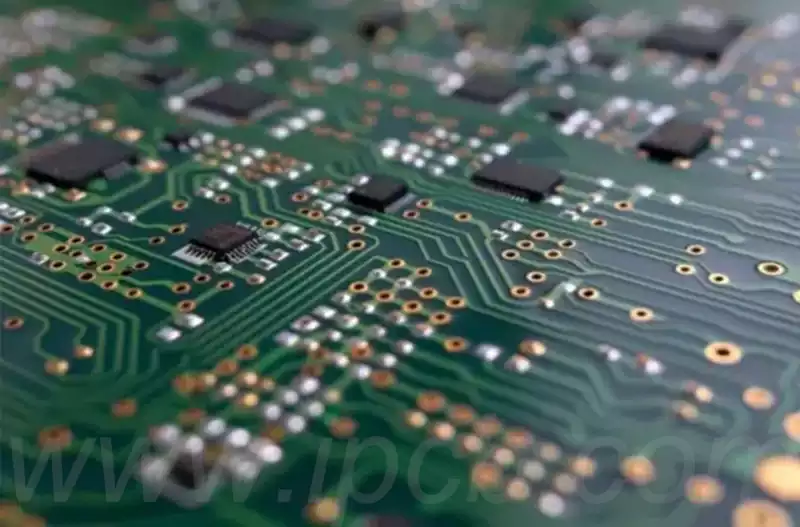

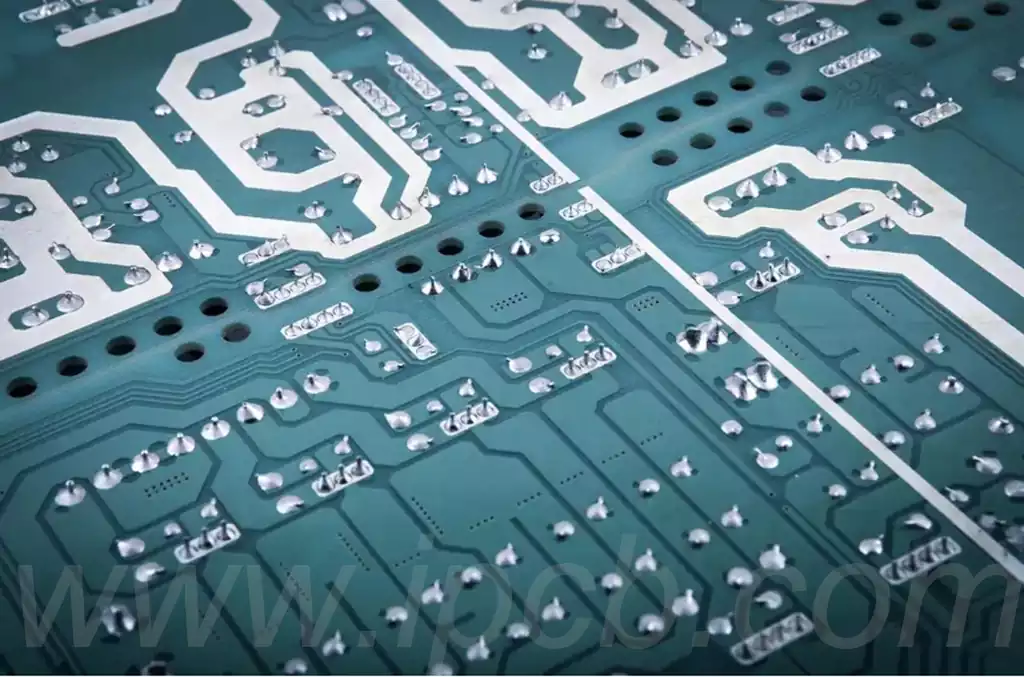

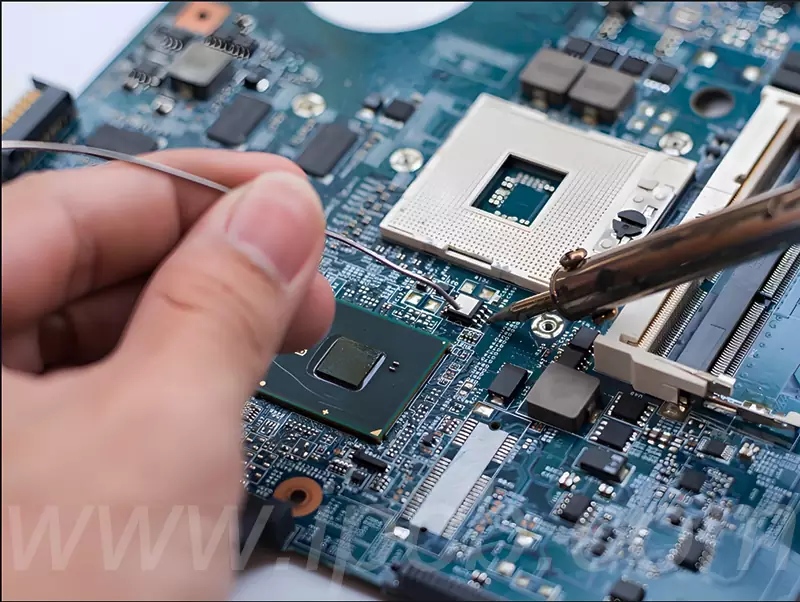

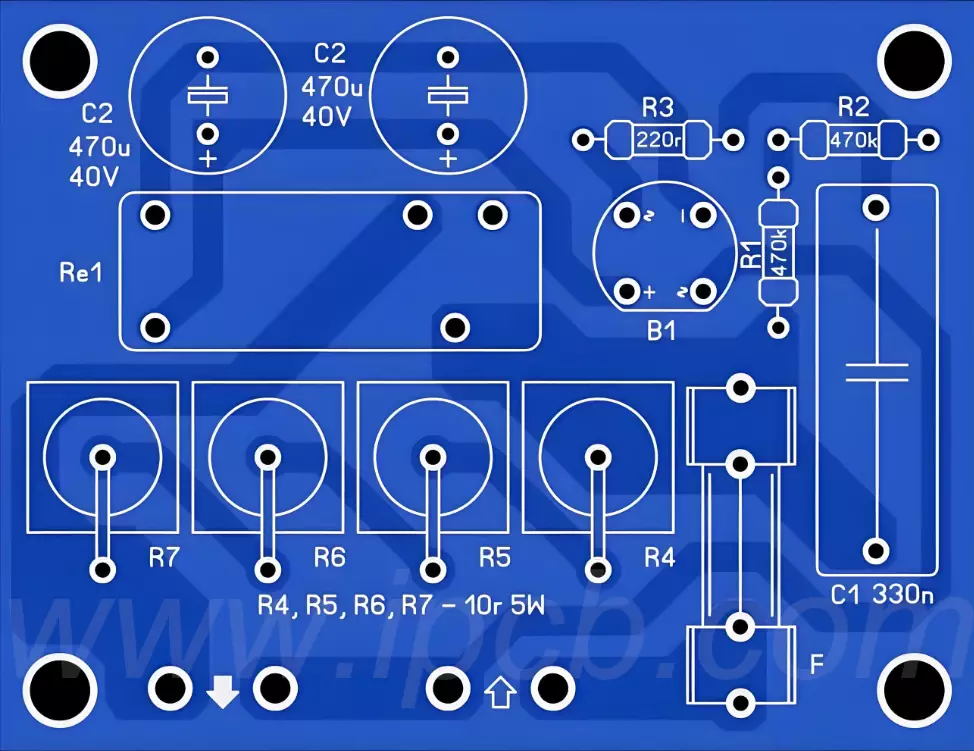

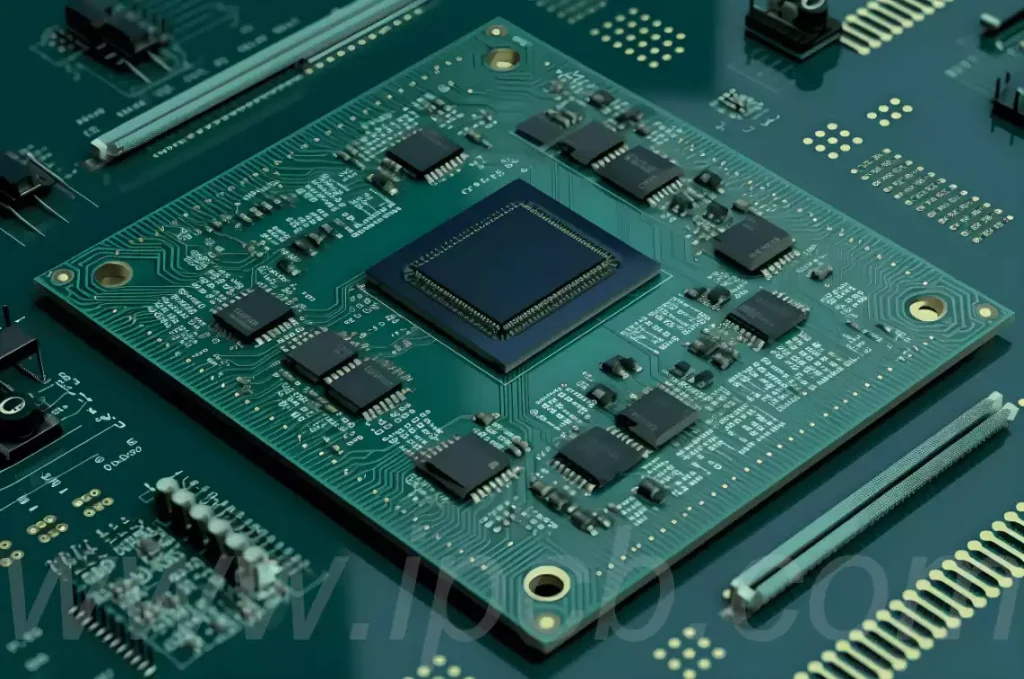

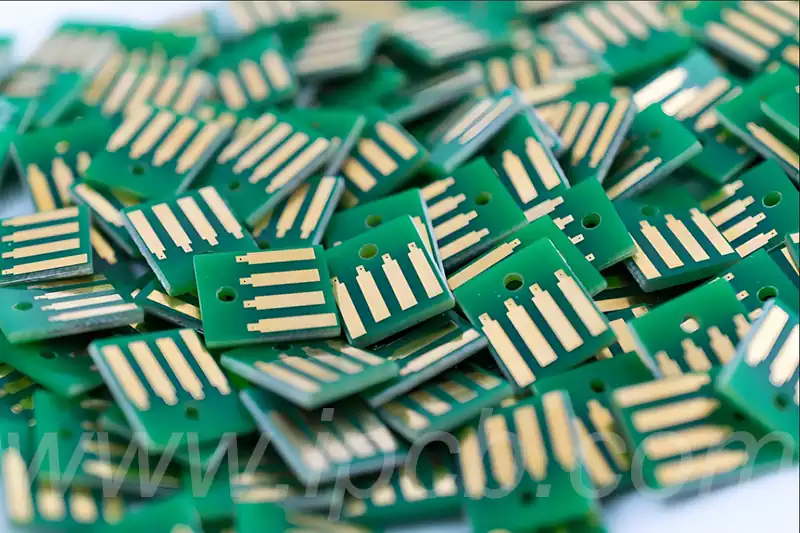

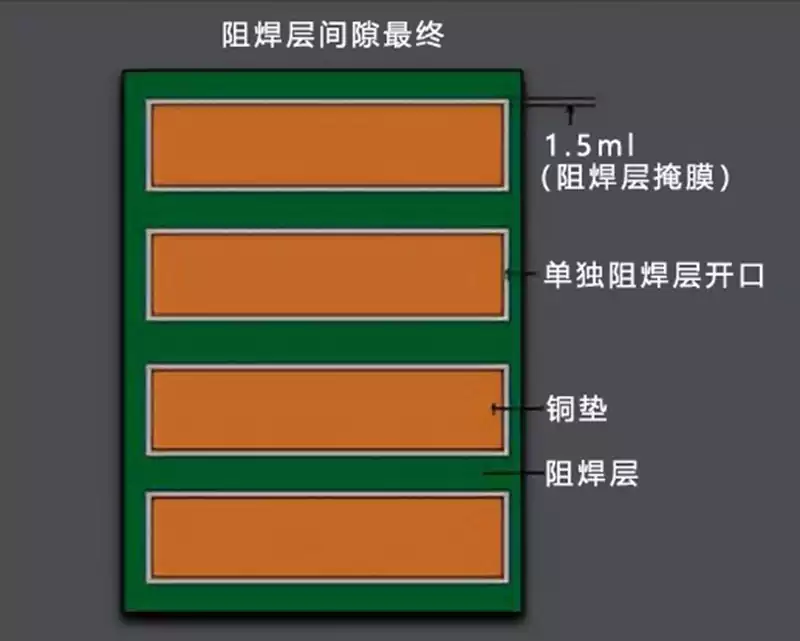

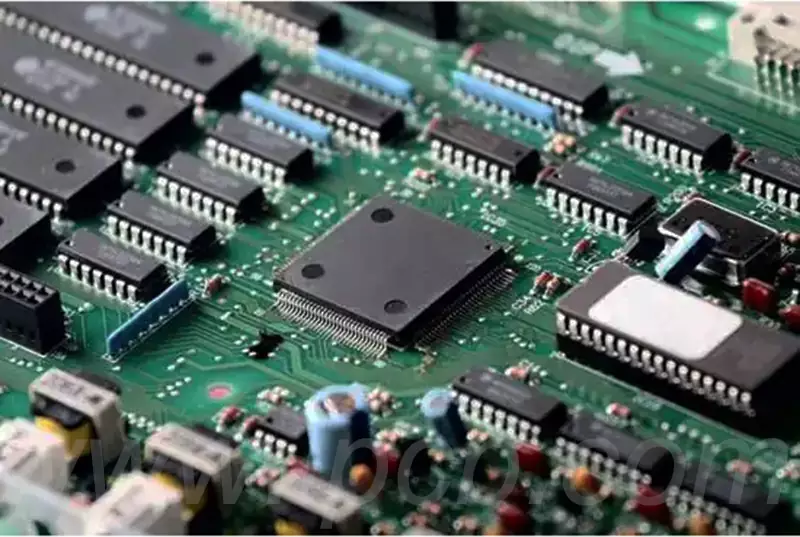

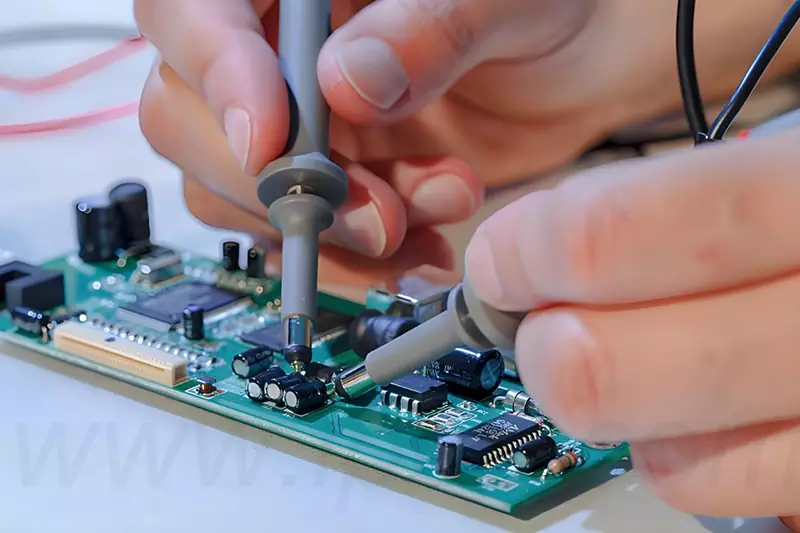

PCB solder pad came off refers to the phenomenon that the solder pad is separated from the printed circuit board. The solder pad is a conductive graphic on the PCB to provide electrical connections, as a necessary medium for soldering electronic components and PCB circuit boards, the solder pads play a vital role in the […]