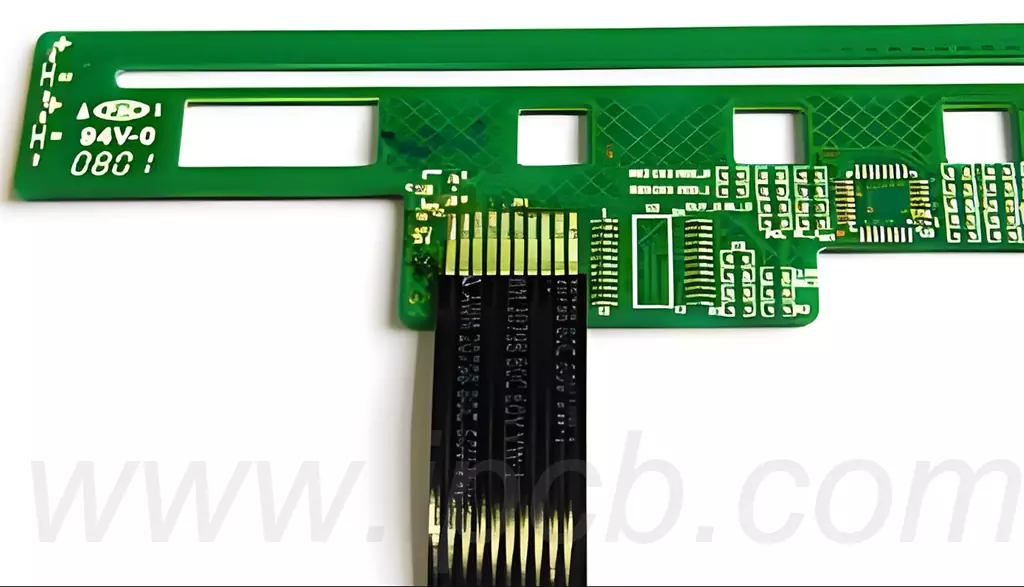

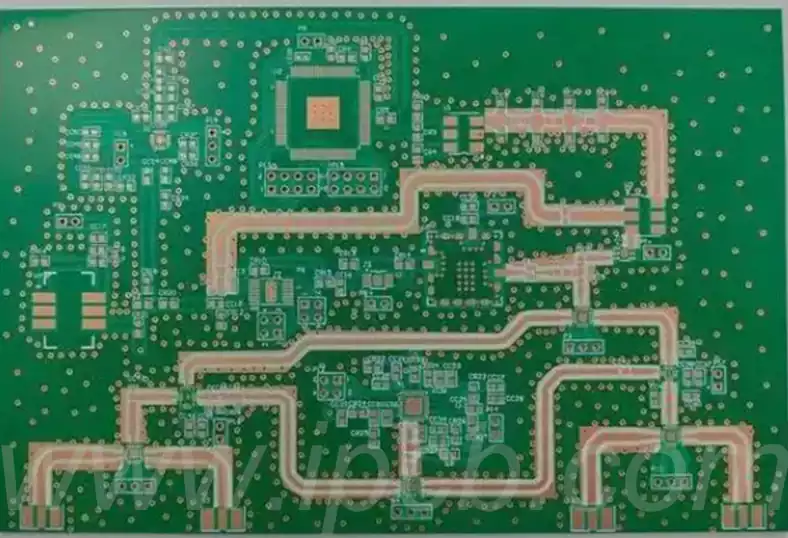

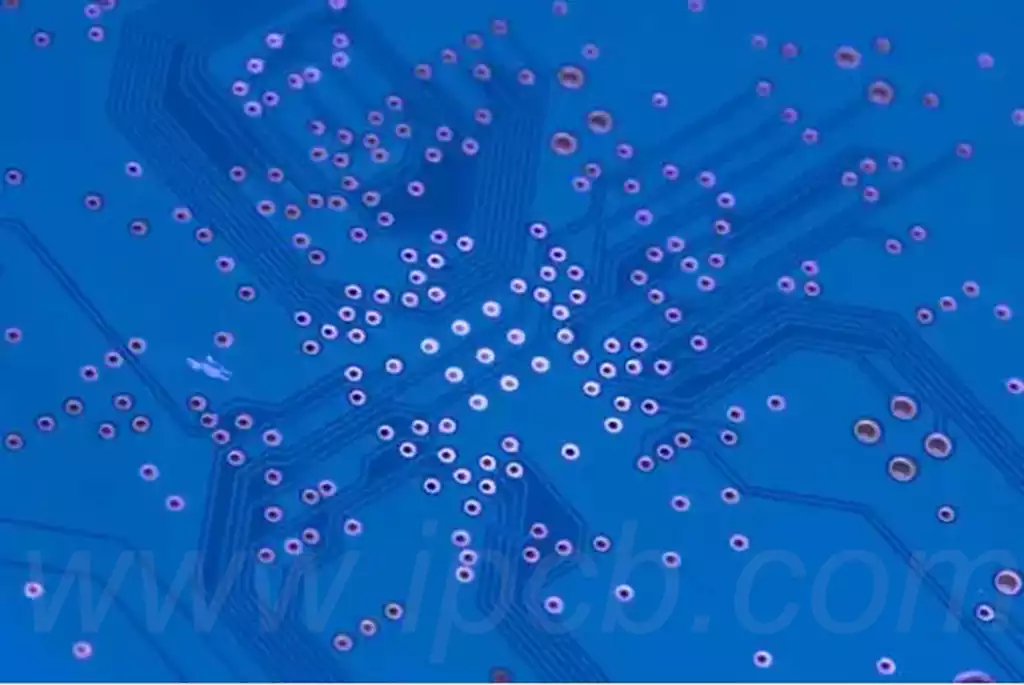

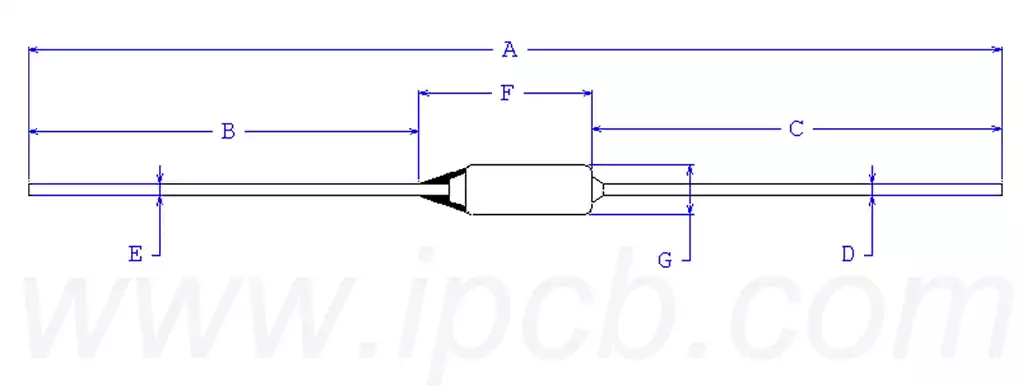

Glass pcb and TGV carrier board manufacturing process

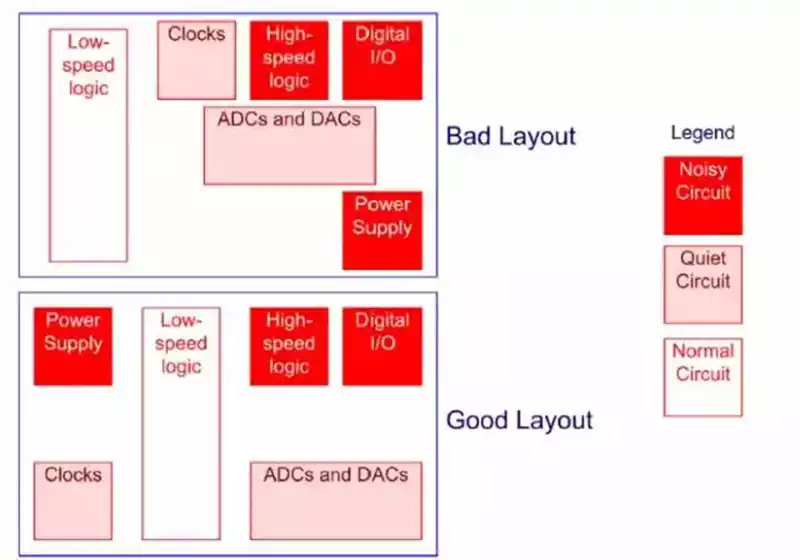

Glass pcb and their derivatives, glass through hole (TGV) carrier board,has become indispensable core components for various high-tech electronic products. They are not only widely used in liquid crystal display (LCD),organic light-emitting diodes (OLED) and other display technologies,but also play an important role in semiconductor packaging, integrated circuit interconnections and other aspects. Mainstream manufacturing techniques […]