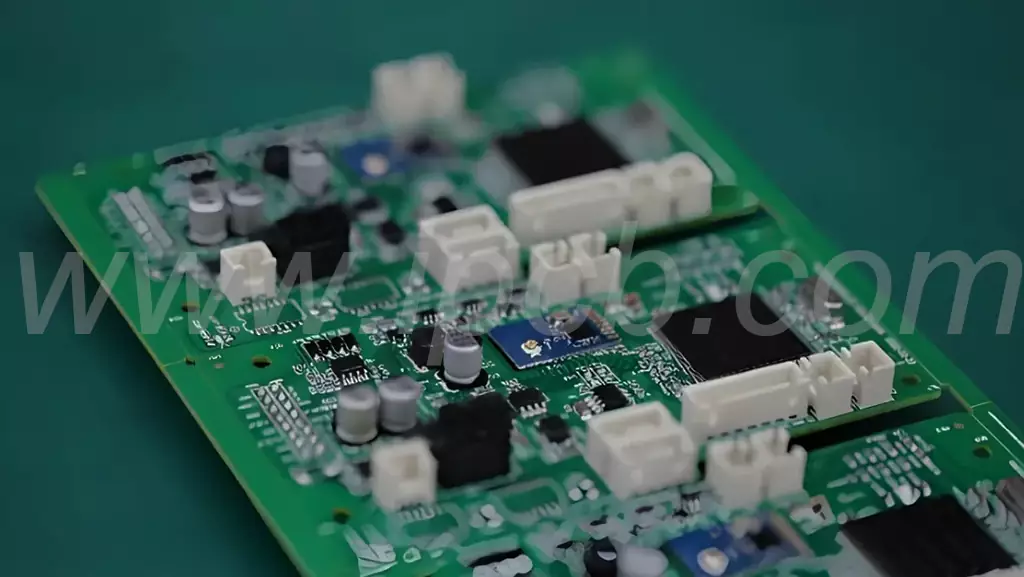

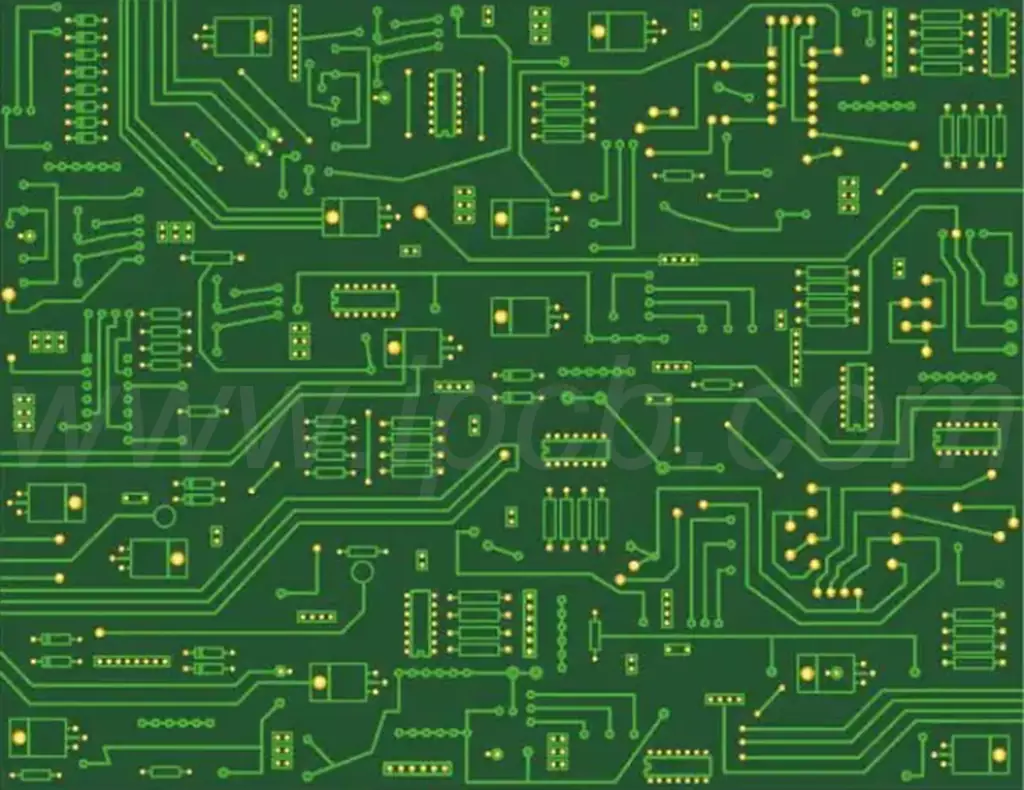

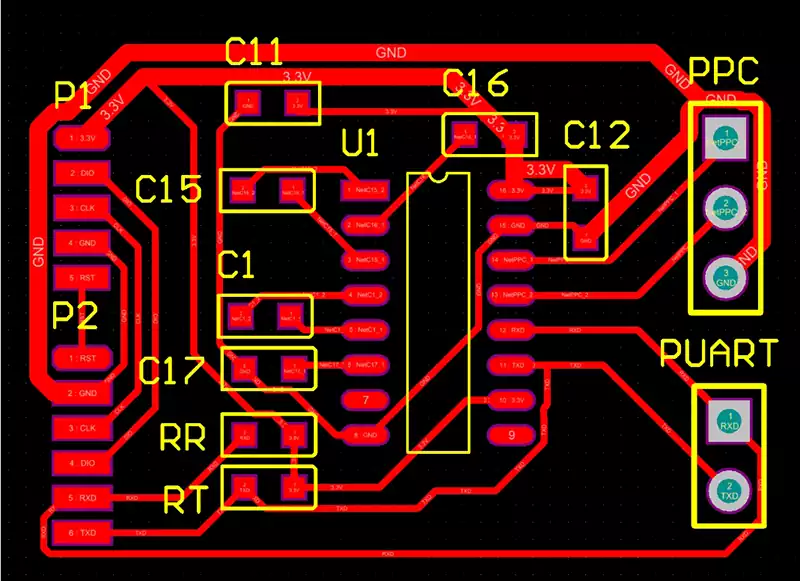

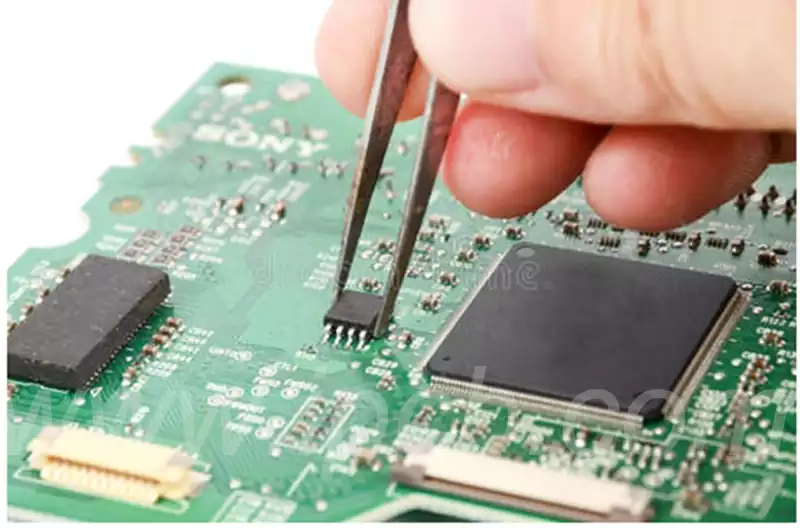

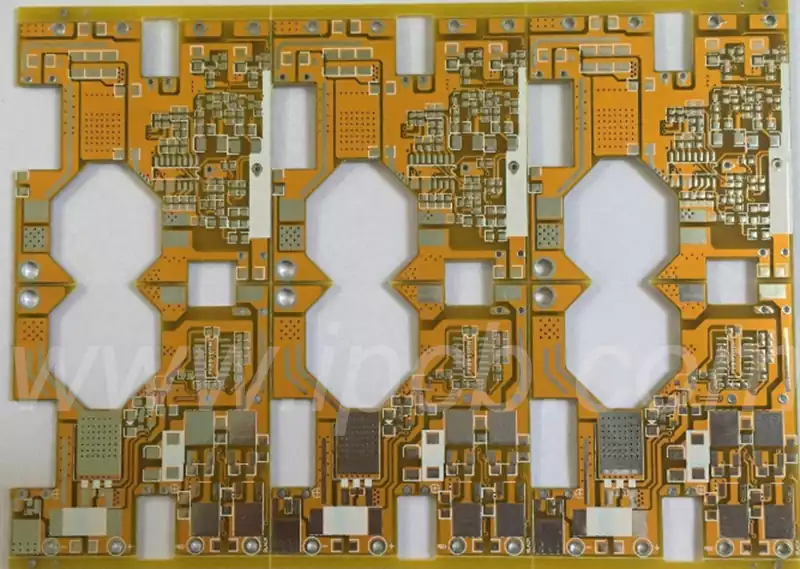

Circuit diagrams are a guide to the world of electronics

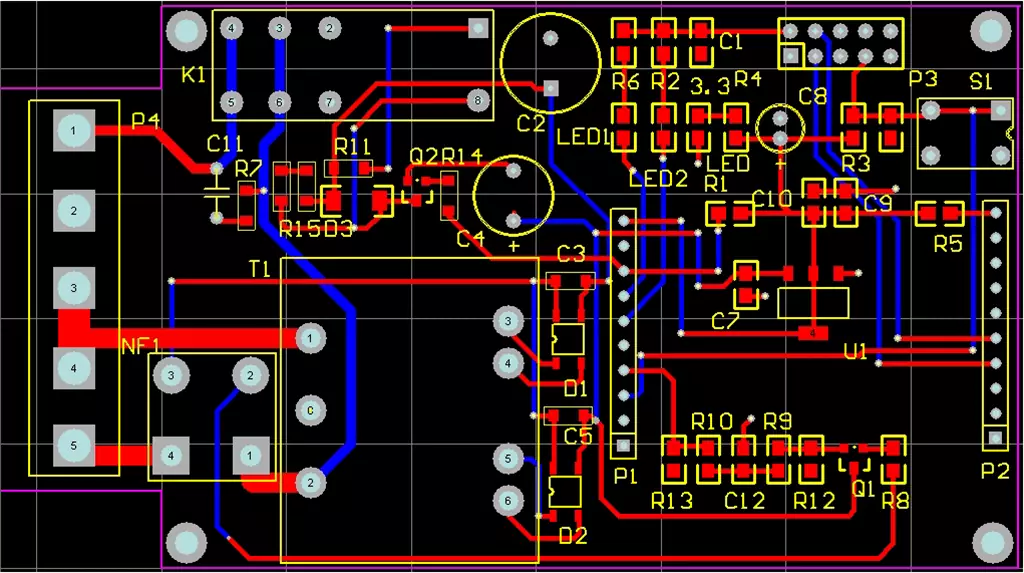

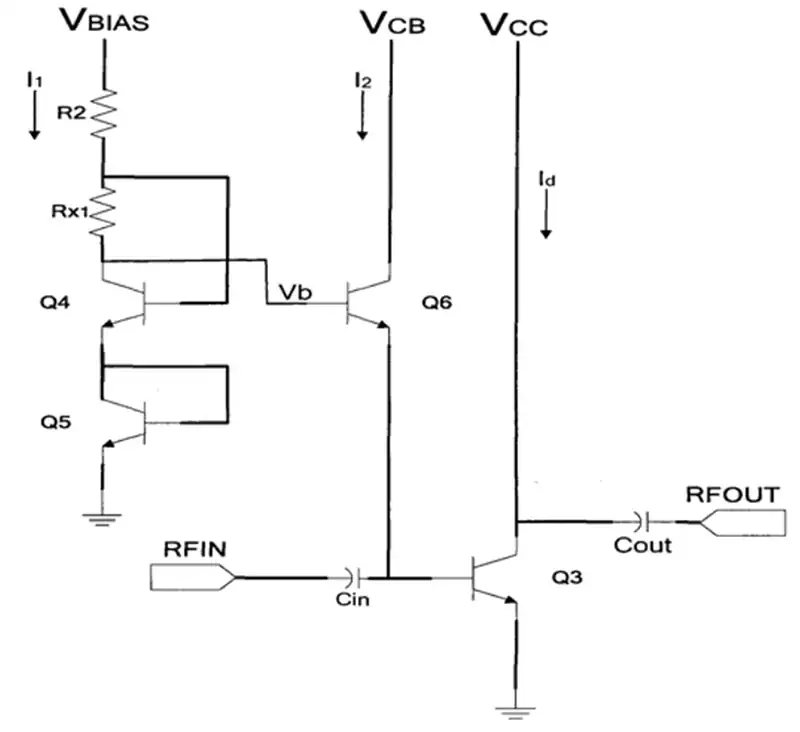

A circuit diagram is a pictorial representation of the connections of a circuit using graphical symbols and lines. It is a combination of specific symbols and lines that clearly shows how the electronic components Q are connected, where the current flows, and how the circuit works. Circuit diagrams can be divided into different types such […]