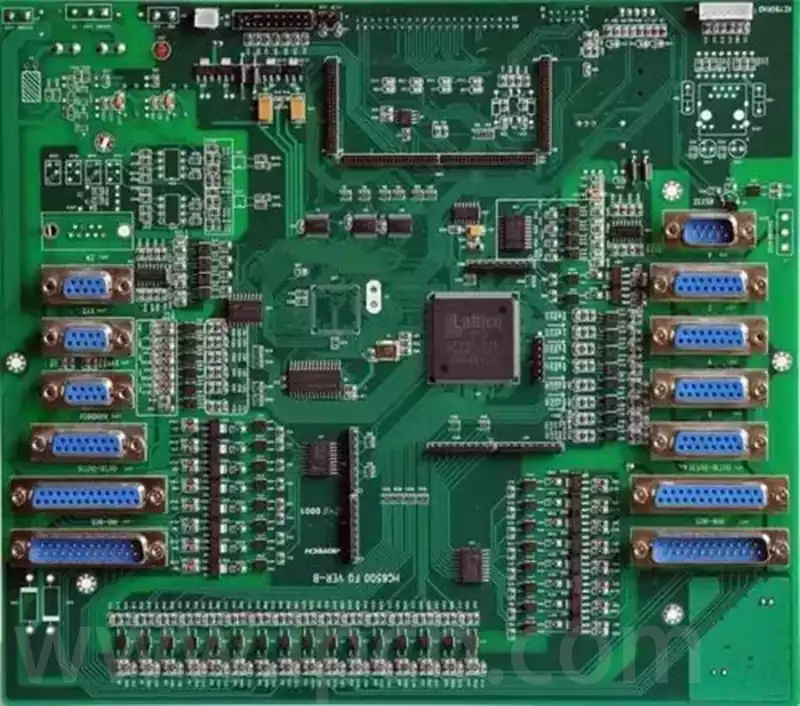

PCB Circuit Board Connection Methods

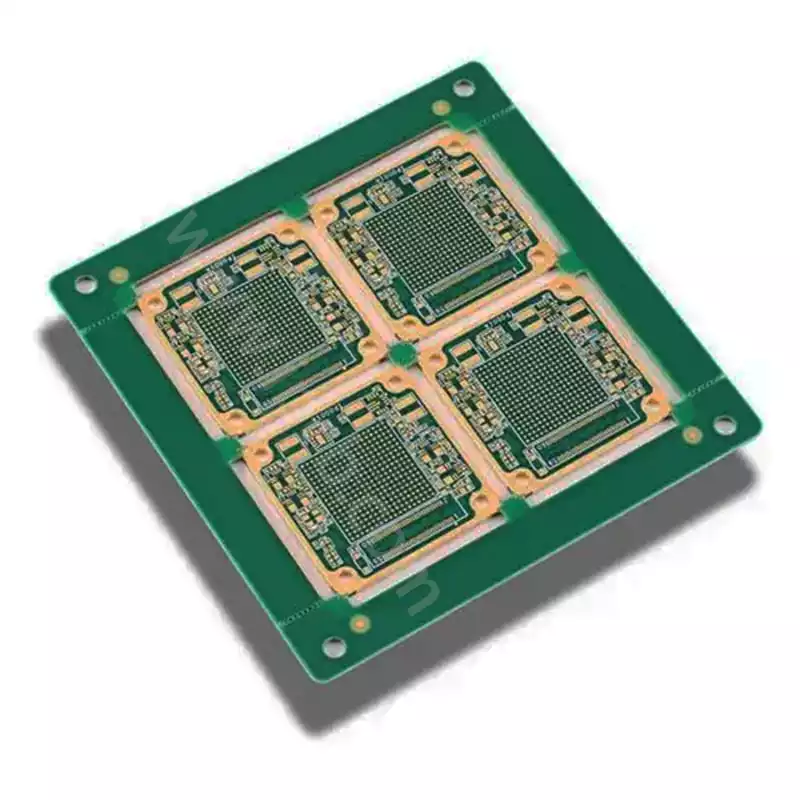

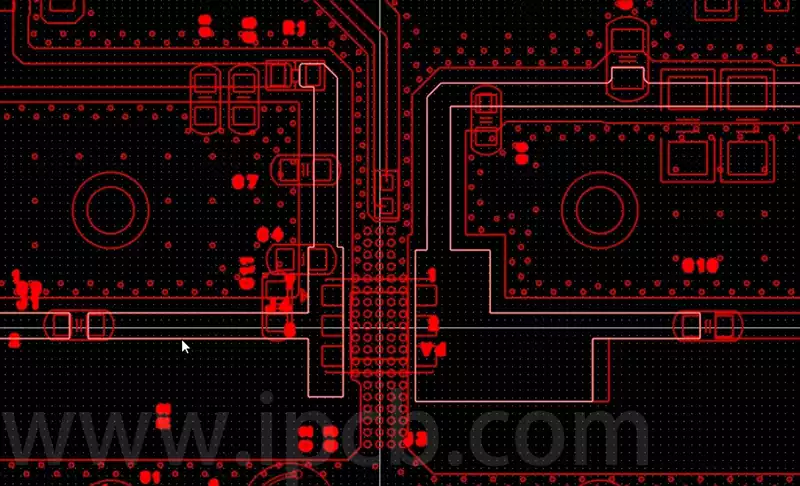

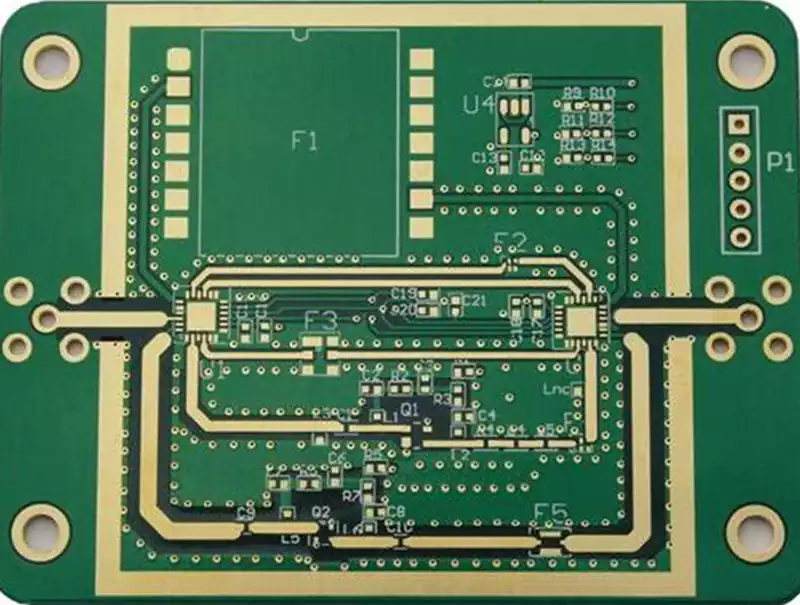

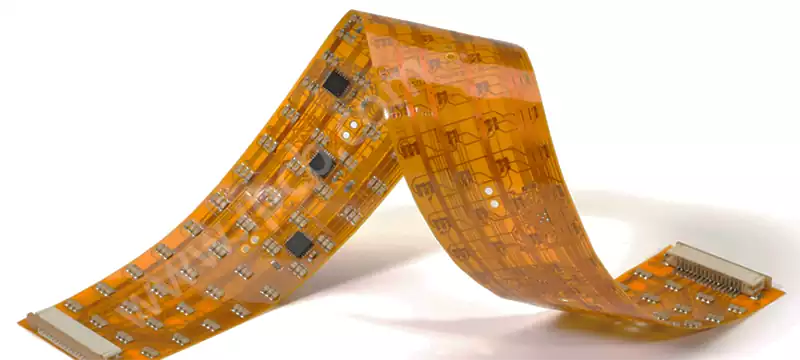

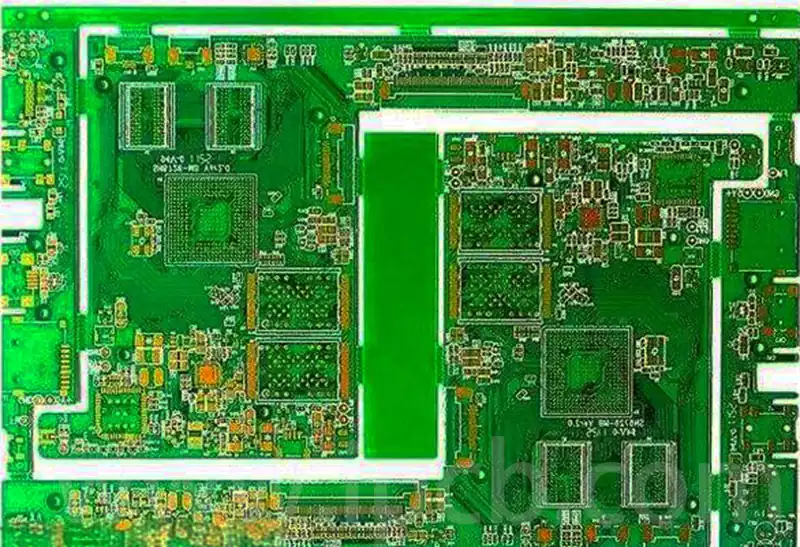

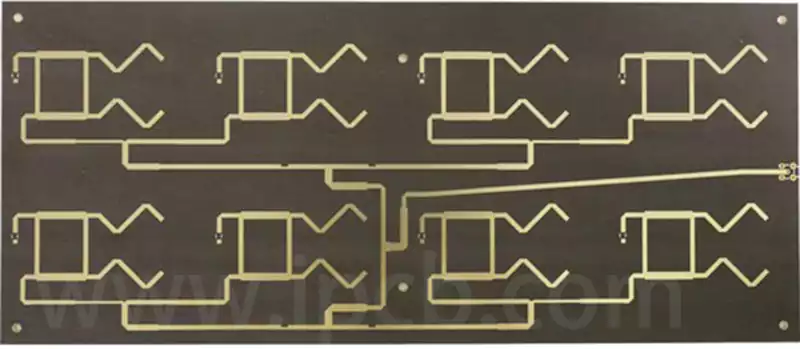

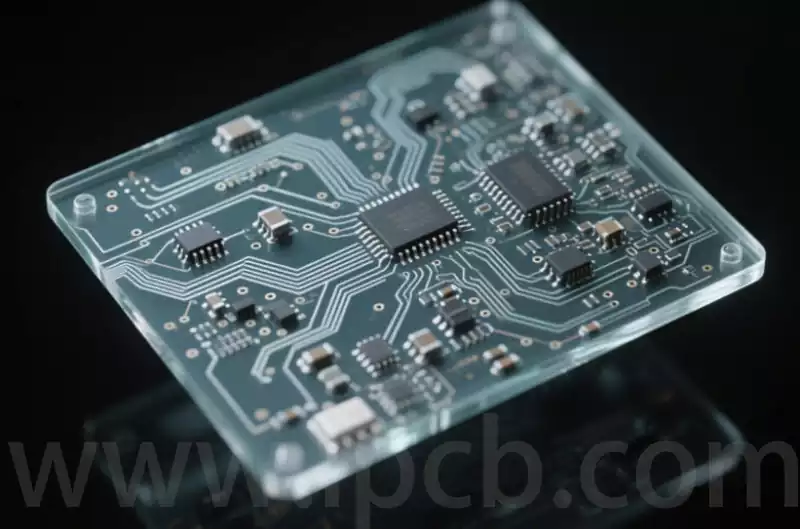

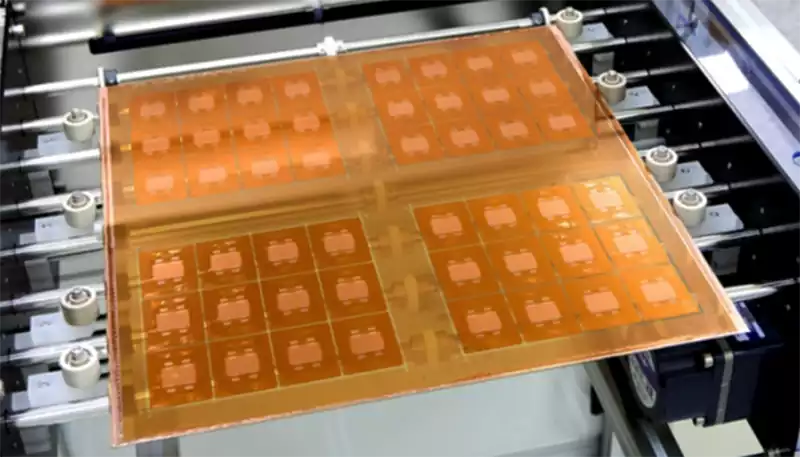

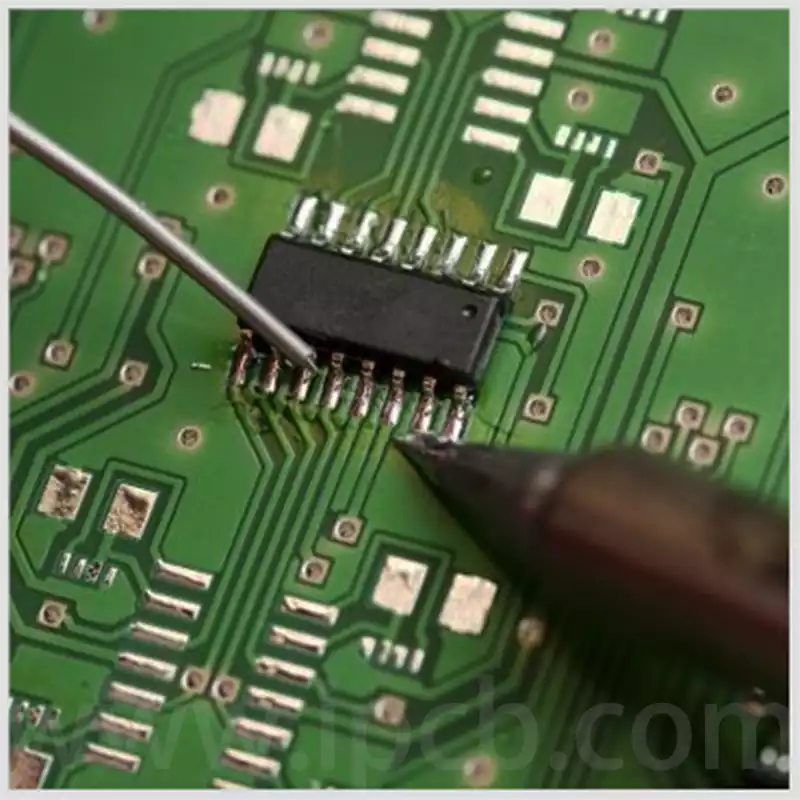

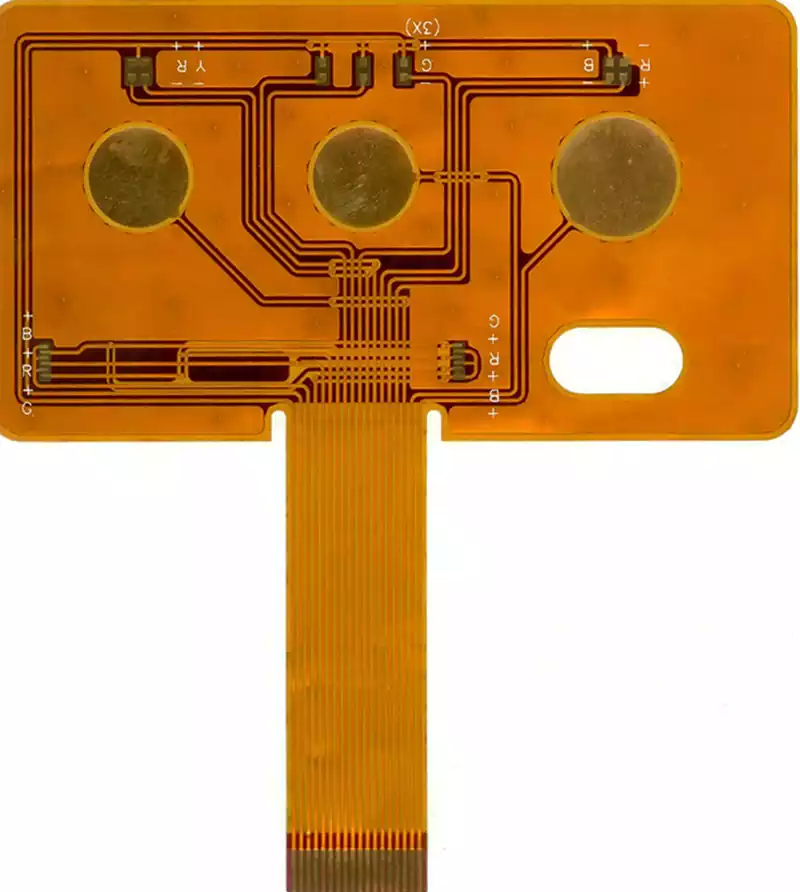

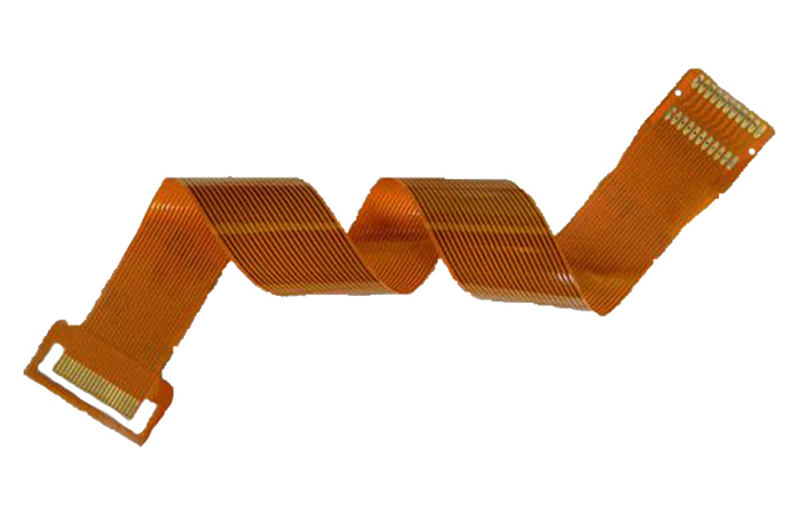

Connections between pcb circuit boards are primarily achieved through conductive connectors, wires, flexible printed circuits (FPC), board-to-board connectors, and soldering techniques. Among these, flexible printed circuits (FPC) serve as a widely adopted connection method, excelling in the creation of reliable, high-density electronic products. Their lightweight, thin profile and excellent flexibility make them highly suitable for […]