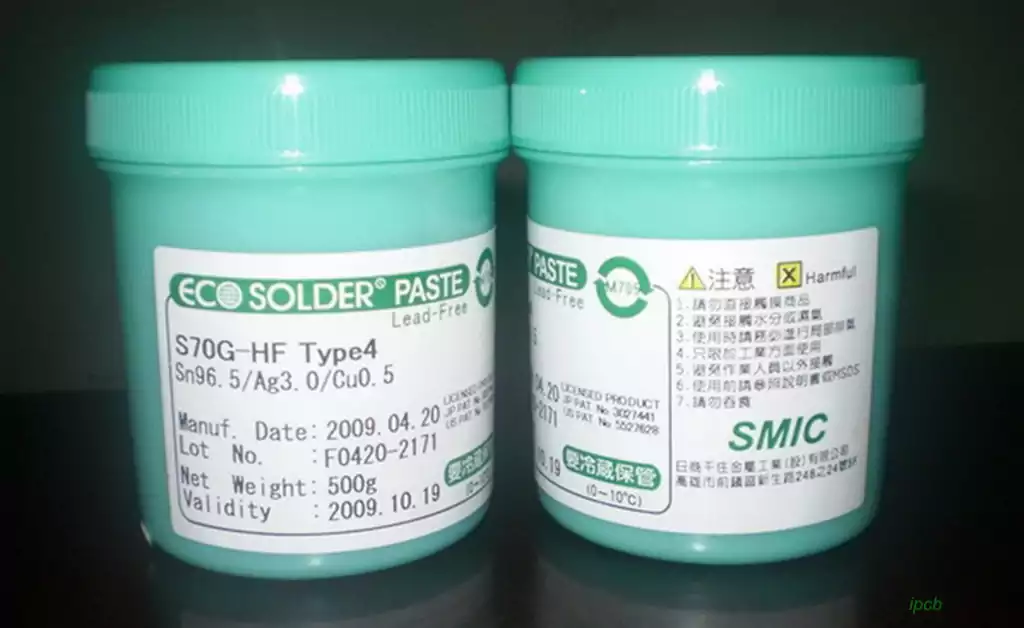

Flux residue effects and how to clean flux residue

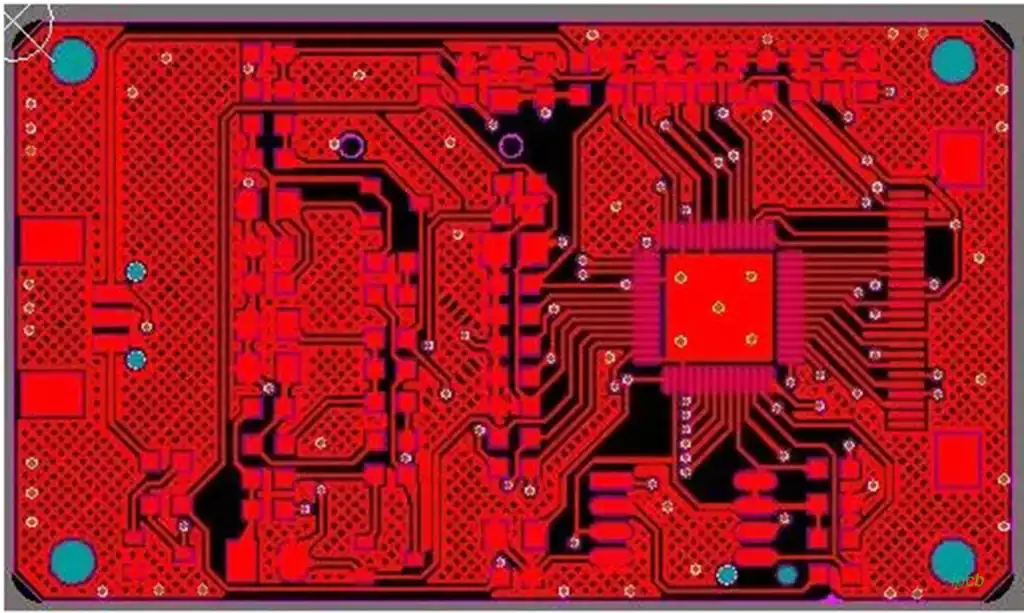

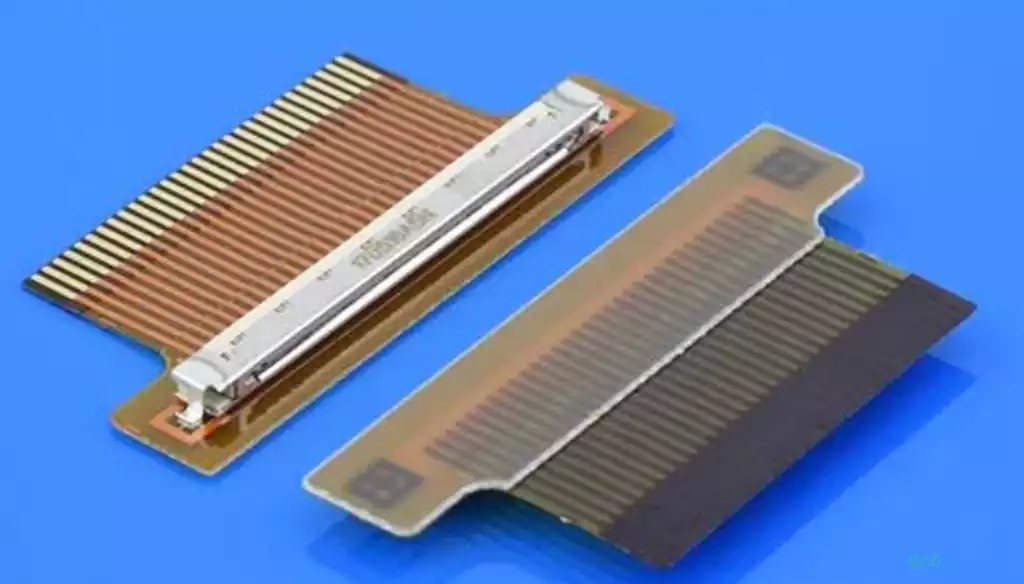

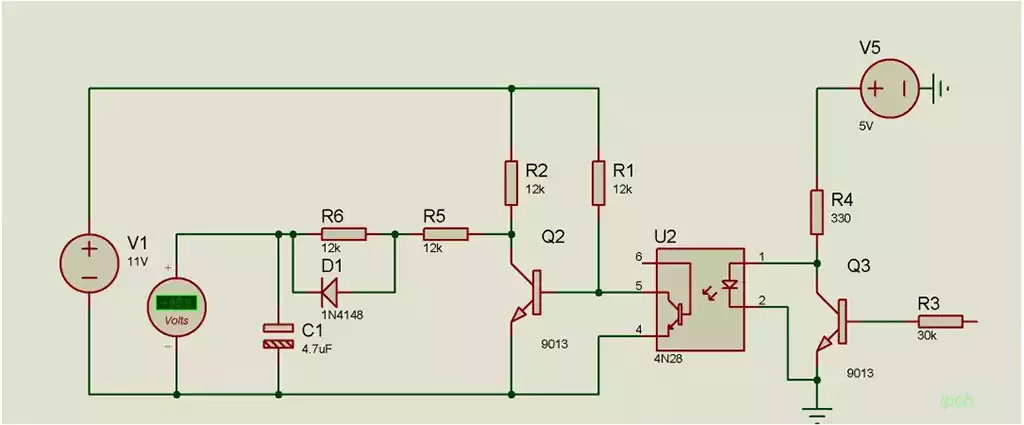

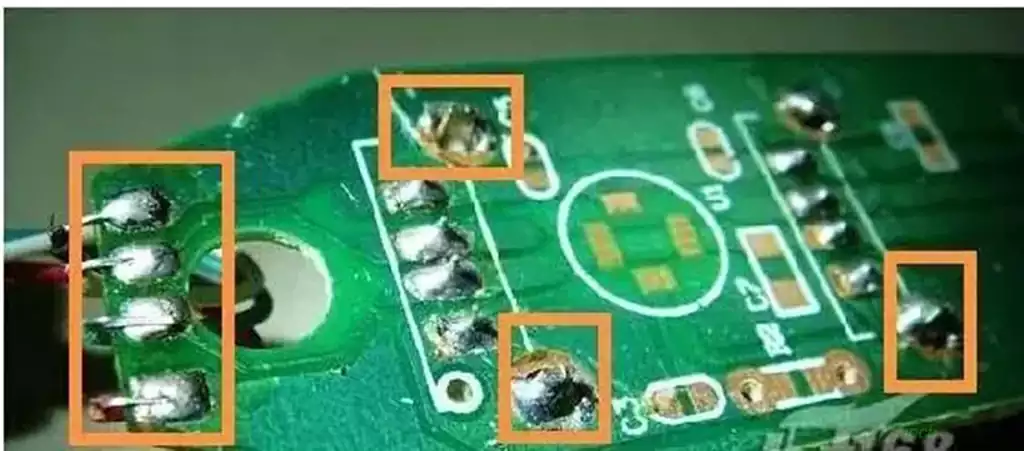

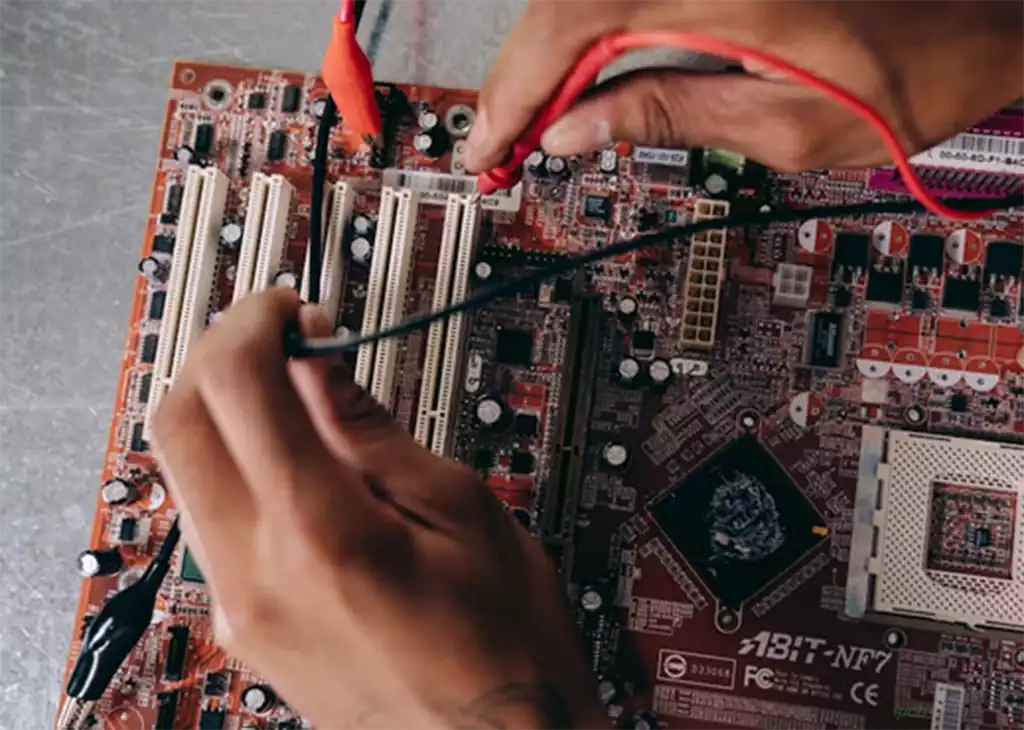

In the manufacturing process of electronic products, flux, as an important soldering auxiliary material, plays a key role in connecting electronic components with circuit boards. However, while flux brings convenience, its residue problem has also become a challenge that cannot be ignored. Excessive flux residue not only affects the appearance and quality of the product, […]