What is a presensitized PCB board?

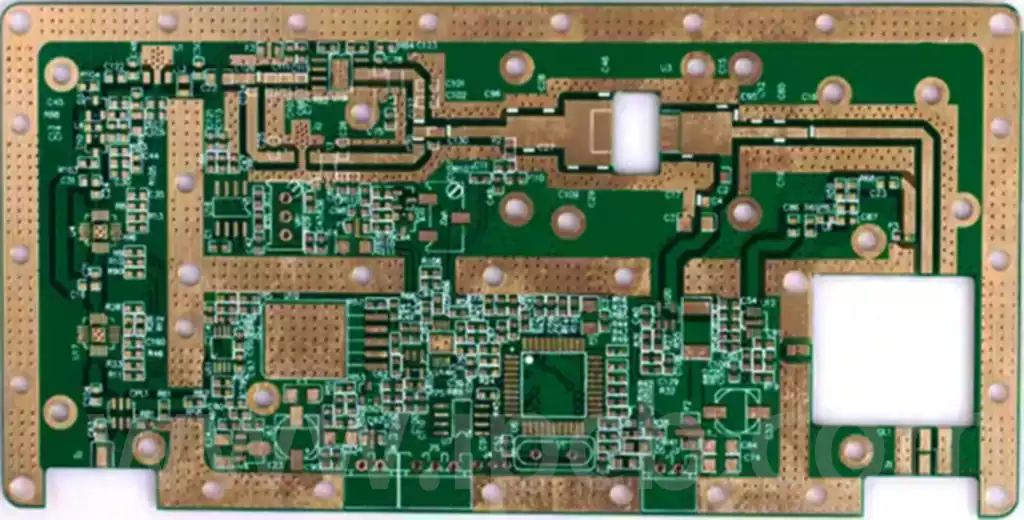

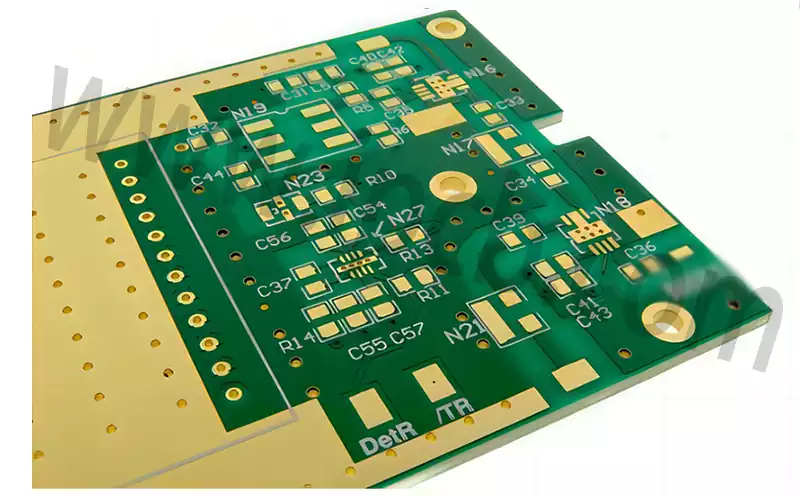

What is a presensitized PCB board?A presensitized pcb board is a special type of printed circuit board with a photosensitive surface. It supports photolithography technology and can be adjusted using ultraviolet light. Despite common misconceptions, presensitized PCBs are similar to standard copper-clad PCBs, but essentially involve transferring graphics onto the board. Presensitized printed circuit boards […]