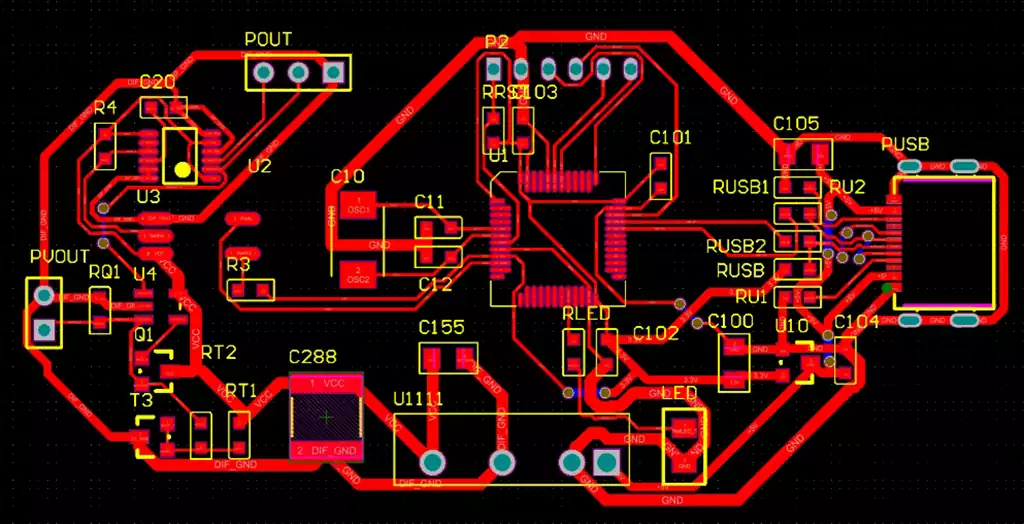

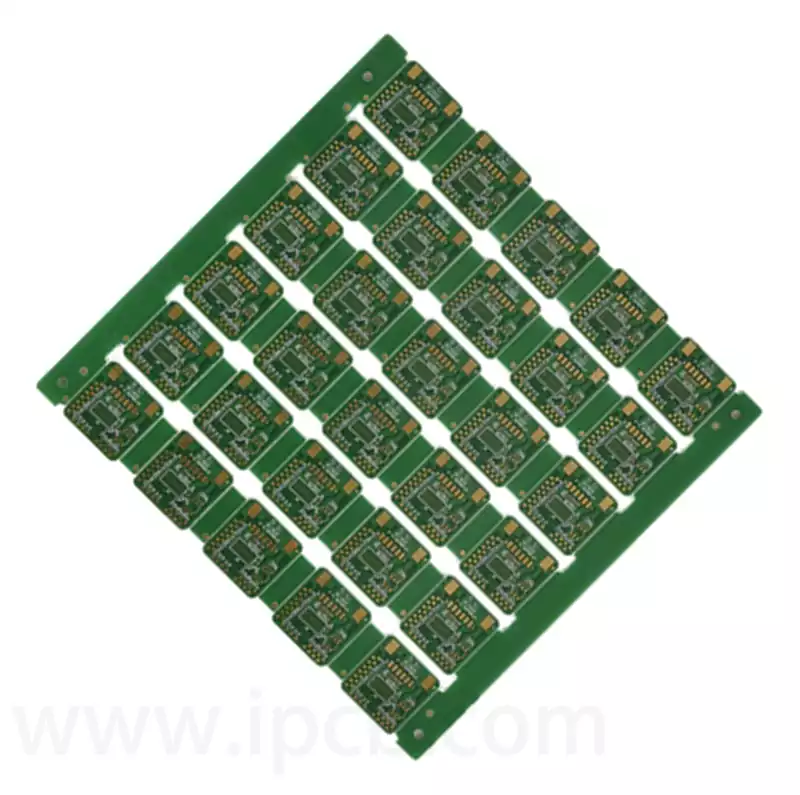

HDI pcb stackup structure and rational design

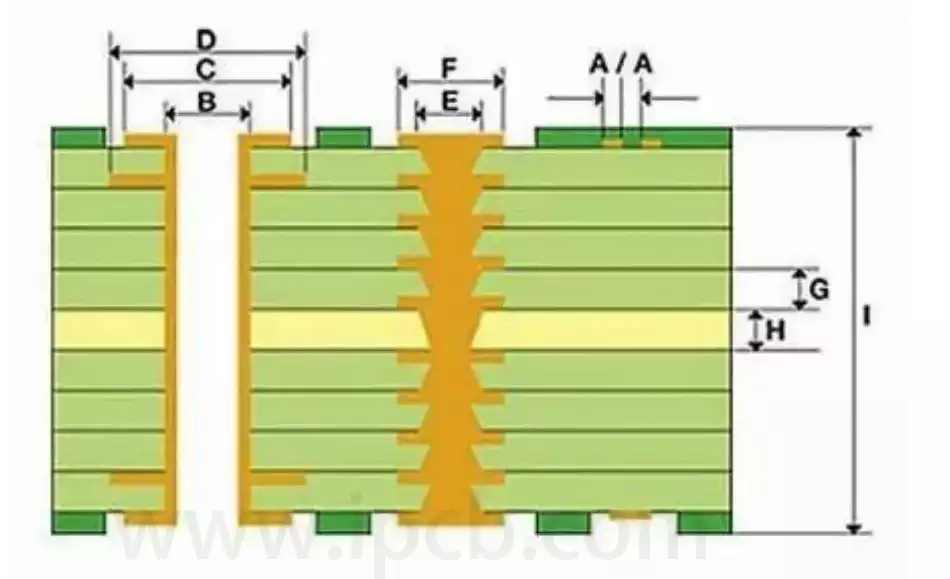

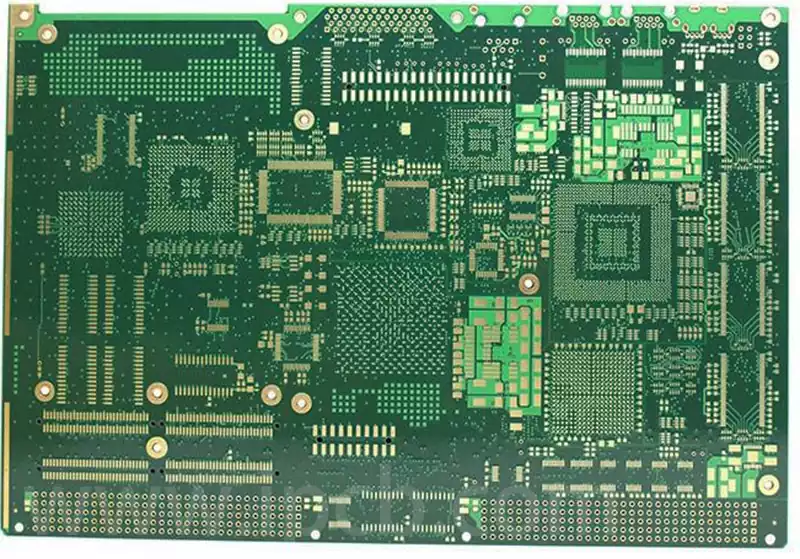

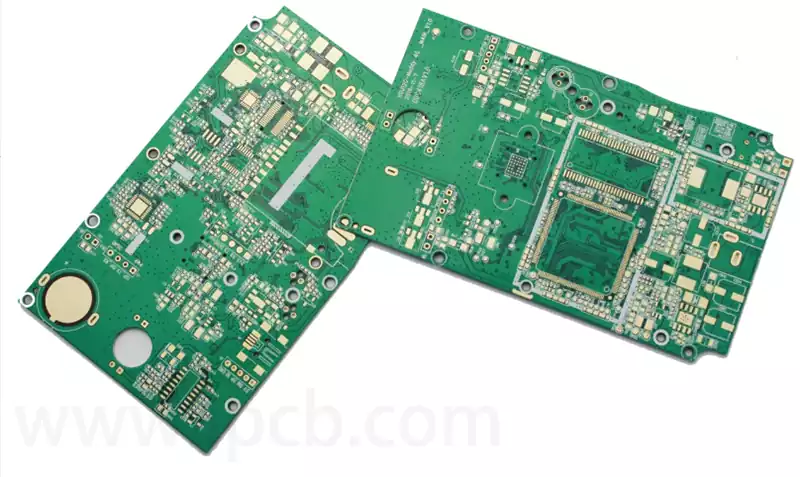

HDI PCB is usually manufactured using the stackup method, the so-called ‘stackup’ refers to the formation of complex multilayer structures through the stacking and compression of multiple layers of circuit board materials. The more layers are stacked, the more difficult the board’s performance and process will be. HDI pcb stackup structure is usually expressed in […]