Difference between microstrip antenna and patch antenna

Patch antenna is a commonly used antenna for wireless communication and is widely used in many small electronic devices. It has the advantages of miniaturisation, easy fabrication, easy integration and

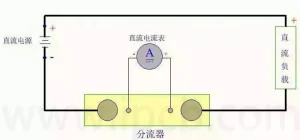

Role and application of current divider

A current divider, also known as a current shunt, is a component used to distribute current to support multiple circuits. It divider current from one circuit to multiple branch circuits,

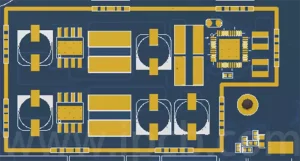

pcb shield design and function

PCB shield cover is a component used to protect the internal components of electronic equipment from electromagnetic interference, generally used in places where it is necessary to prevent the leakage

The role and application of pcb board clamp

A pcb board clamp is a fixture used to hold and clamp circuit boards. It plays a very important role in the assembly and manufacture of circuit boards. There are

Comprehensive application analysis of 4 pin connector in PCB design

In modern electronic design, connectors play an irreplaceable role as bridges between modules. In particular, 4 pin connectors are widely used in consumer electronics, industrial control, automotive electronics, smart home

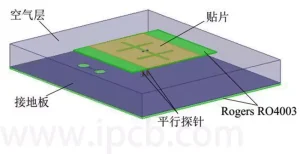

Key Considerations for RF Microwave PCB Design and Application

PCB High Frequency Board (RF Microwave PCB) is a special type of circuit boards used to process signals at higher electromagnetic frequencies. This type of board is commonly used in

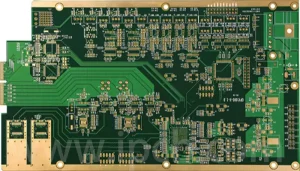

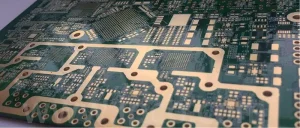

Computer pcb technology development and application

The computer pcb is an important electronic component that is widely used in various electronic devices such as computers, mobile phones, TVs and so on. It is the core component

Comprehensive Analysis of Fusible Semiconductor Protection Devices

In modern electronic design, fault protection mechanisms such as overcurrent, overtemperature, and short circuit are indispensable. Traditionally, people usually use fuses, PTC thermistors, or electronic circuit breakers to protect power

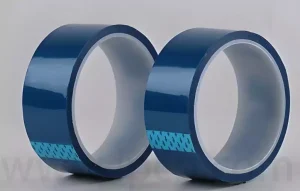

Application areas and functions of peelable solder mask pcb

A peelable solder mask PCB is a printed circuit board with a peelable solder mask (temporary solder resist) that protects certain areas during surface preparation or assembly. That is, sometimes

Materials and functions of breakout board

A breakout board, called both an adapter board and a breakout board, is a board-like device used to connect, convert, or extend the functionality of electronic equipment. It can establish

Exposed copper on pcb causes harm and repair methods

Exposed copper on pcb refers to the surface of the circuit board part of the copper foil is processed to remove the exposed place called exposed copper, also known as

Alkaline etching technology for circuit boards

Alkaline etching solution for circuit boards, also known as passivation solution, is one of the widely used chemical etching solutions in the electronics industry for removing unwanted copper materials from

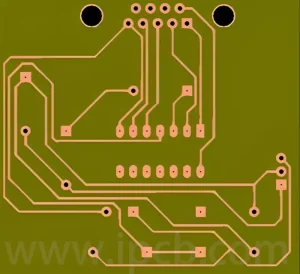

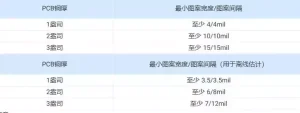

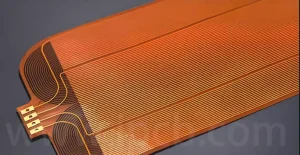

PCB board copper thickness and design guidelines

PCB board copper thicknesses are generally classified as 1oz (35μm), 2oz (70μm) and 3oz (105μm). Of course, the copper thickness depends on the type of board you are making. Copper

Bluetooth pcba board application areas and development

Bluetooth Data Module is a PCBA board with integrated Bluetooth functionality for short-range wireless communication. By integrating the chip and peripheral hardware circuits onto the PCB and developing inbuilt programs

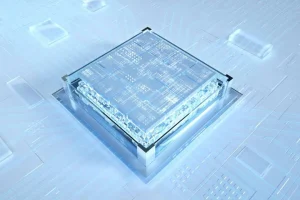

What is semiconductor packaging?

What is semiconductor packaging? Semiconductor Packaging is the process of processing a tested wafer into an individual chip according to the product model and functional requirements. The purpose of traditional

Inside the Structure of a PCB Splitter

In modern electronic devices, power management boards are key to maintaining stable operation. As the functions of devices become more and more abundant, a single power input must support multiple

Types and cost of hdi pcb

HDI PCB definition, High Density Interconnect Board, is a circuit board with high line distribution density using micro-blind/buried hole technology. It is able to achieve higher line density and finer

Application and Manufacturing of Thermistors in Circuit Boards

On a circuit board, RT usually stands for Thermistor, a component that is extremely sensitive to temperature. The resistance value of a thermistor changes significantly with temperature, so by measuring

PCB Test Point Layout

PCB test points may look like just some pads or exposed copper skins, but their role in the entire production, debugging, testing and repair process is very critical. If the

Glass PCB Technology and Its Future in High-Performance Electronics

With the development of cutting-edge technologies such as 5G, artificial intelligence, and the Internet of Things, electronic products have put forward higher requirements for high-frequency, high-speed, low-loss, and low-dielectric circuit

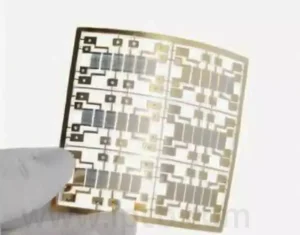

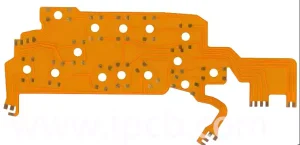

Future challenges and application for transparent flexible pcb

A transparent flexible PCB is a pcb board that can be bent and has a certain degree of flexibility without affecting its functionality. It is made of flexible materials such

Key points and strategies for soldering flexible circuit board

FPC flexible circuit board is widely used in modern electronic products due to their thin, lightweight and bendable characteristics. However, its unique physical properties also bring many challenges to the

Deformation and Delamination Prevention in Flex Board Manufacturing

In the production of flex board, material deformation and delamination are important factors affecting product quality. In order to avoid such problems, the following detailed coping strategies can be adopted:

Key considerations and applications for high speed digital pcb

High speed digital pcb is circuit boards that can support high speed digital signal transmission, and are usually used in scenarios where the frequency of digital logic circuits reaches or