PCB Delamination Causes and Prevention

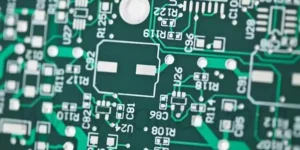

PCB delamination is the phenomenon of partial separation between layers of a printed circuit board (PCB) during manufacture or use. This separation is usually characterized by bubbles or blisters on

The pcb layers design overview

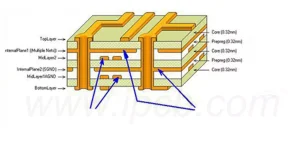

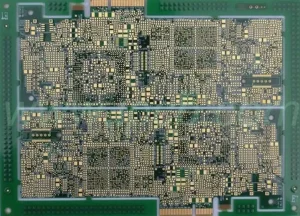

The number of PCB layers is the number of layers it has in the vertical direction (usually the Z-axis). In short, it is how many layers of wiring are laid

what is a pull up resistor

In digital circuits, a pull up resistor (pull up resistors) is a resistive device used to ensure that the input signal is at the desired logic level when an input

Advantages of low volume pcb assembly

Low volume PCB assembly refers to the assembly and processing of circuit board components in relatively small quantity ranges. This type of assembly typically involves orders with lot sizes between

Body to body clearance for smt parts

In the printed circuit board (PCB) design process,body to body clearance for smt parts refers to the physical distance between different surface mount components (such as resistors, capacitors, chips, etc.).Ensuring

4 Reasons Why Electrical Impedance Is Important in PCBs

In this article, we will explore what electrical impedance is, why it is important in PCB design, and how proper impedance control can save you time, money, and frustration. By the end, you’ll understand why partnering with an experienced PCB manufacturer like us can make all the difference in your project’s success.

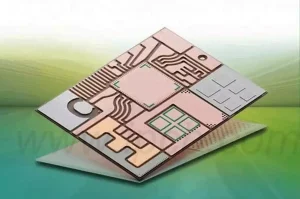

Porcelain Ceramic Substrate Crown Circuit Board

Porcelain ceramic substrate crown circuit boards are a special type of circuit boards that are usually made from high temperature ceramic materials. They are known for their excellent electrical insulation

Characteristics and Applications of ABF Substrates

ABF substrates (Ajinomoto Build-Up Film) is a high-performance substrate for semiconductor packaging, known as “building block substrate”, which is mainly used in high computing performance chips such as CPUs, GPUs,

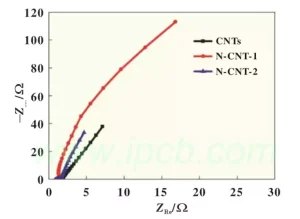

The Importance of Impedance

What is impedance? The impedance of an alternating current in a circuit with resistance, capacitance, or inductance is called impedance, and is often denoted by the letter Z in ohms.

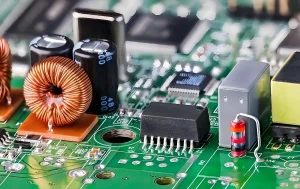

Computer Board Components and Materials

Computer board components refer to the hardware parts that make up a computer system, focusing mainly on the motherboard and the other components it connects to (such as the CPU,

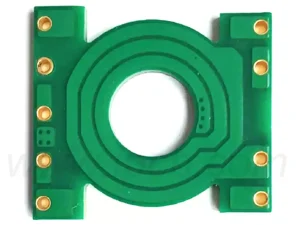

Optimization of coil on pcb

What is a coil on pcb? A coil on pcb is formed by winding wires into a spiral (or other geometric shape) to create an inductive element.The coil produces a

Furnace control board Overview

Furnace control board, also called furnace PCB board, is an important components used in a variety of heating appliances and are responsible for controlling the furnace’s operating status, temperature regulation

what is pcba test in mobile

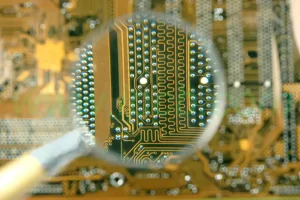

I.Overview of pcba testing standardsVisual inspection: through the magnifying glass and microscope and other tools on the circuit board appearance check to ensure that there are no welding errors, component

A Good Solar Light Circuit Board

In an era marked by environmental consciousness and a shift towards renewable energy, solar light technology has emerged as a beacon of sustainability. At the heart of this technology lies an often overlooked yet critical component: the Printed Circuit Board (PCB). Solar light circuit boards are the unsung heroes that power everything from small garden lights to large-scale solar lighting systems, enabling efficient energy conversion, storage, and distribution.

Energy Harvesting PCB Technology

An energy harvesting PCB is a solution that integrates multiple energy harvesting technologies onto a circuit board to harvest and convert energy from the surrounding environment into electricity. It typically

Free PCB Layout Program Choosing the Best Tool

In the world of electronics, the design and development of printed circuit boards (PCBs) is a crucial aspect that requires precision and expertise. PCB layout programs are essential tools that

What is a motor driver board?

What is a motor driver board?A motor driver board is a circuit board that is used to control the motor so that it can operate properly. It is an electronic

what is a printed circuit board made of

Printed circuit board material composition refers to the relationship between the combination of various materials in the PCB board. Generally speaking, PCB boards can be divided into a variety of

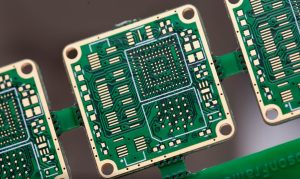

Advantages and Processes of Custom PCB

Custom PCB is circuit board that are designed and manufactured according to specific needs and applications. Compared to standardized circuit boards, custom PCBs can be perfectly adapted to the size,

5 Sections for a Better Understanding of PCBA Contract Manufacturing

PCBA contract manufacturing is a critical service in the electronics industry. It involves outsourcing the assembly of electronic components onto a printed circuit board (PCB) to specialized manufacturers. This process

Printed Circuit Board Price Influencing Factors

Printed circuit boards (PCBs) are an important and indispensable part of various electronic devices and are widely used in computers, cell phones, home appliances, and other electronic products.The printed circuit

Importance of Printed circuit board recycling

Printed circuit board recycling refers to the process of treating and reusing discarded printed circuit boards (PCBs). Waste circuit boards contain a large amount of precious metals, such as copper,

PCB Hole Size Design Points

The pcb hole size is usually determined by the design requirements and application. In general, the size of the hole depends on the required current capacity and the size of

Circuit board types of holes

In the electronics manufacturing industry, printed circuit boards (PCBs), as the core components of electronic devices, carry the connection of circuits and signal transmission. As a key element for connection