The Importance of Hard Disk Circuit Board

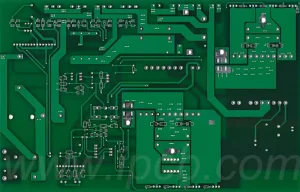

The hard disk circuit board is an important part of the hard disk and one of the core components for data storage and reading and writing. It connects the mechanical

FR-4 fixture is the cornerstone of electronic testing

FR-4 fixture, its core material is FR-4 glass fibre board, which is a composite material with epoxy resin as the binder and electronic grade glass fibre cloth as the reinforcing

welding paste

Welding paste is a homogeneous mixture, a paste with a certain viscosity and good thixotropy, which is a mixture of alloy solder powder, paste flux and some additives. It is

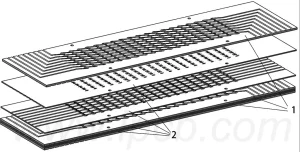

Printed Circuit Board Heat Exchanger

The Printed Circuit Board Heat Exchanger (PCB-HEX) is a highly efficient compact heat exchanger manufactured using printed circuit board technology, which is characterised by the fact that the metal wires

How much does a pcb board cost

While it is true that there are some generally applicable basic processes in the PCB board industry, it is even more critical to carefully select and determine the appropriate production

PCBA processing requirements for PCB boards

In the field of electronics manufacturing, PCBA chip processing constitutes a core link in the product manufacturing process, and plays a decisive role in the performance, stability and durability of

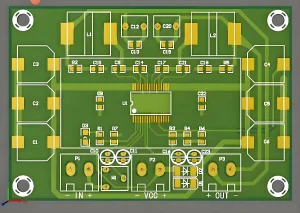

amplifier board

What is an amplifier board? As the name implies, an amplifier PCB is a circuit that can “amplify” a specific input signal. Amplification means obtaining an enhanced signal gain using

Double Sided PCB Soldering Tips

PCB soldering precautions1.EDA365 electronic community suggests that the first task after obtaining the PCB bare board is to carry out visual inspection to confirm that there are no short circuits,

Double sided pcb board manufacturing process challenges

The production process for double sided pcb board consists of several stages, each of which may face a number of technical challenges.The following are some of the major challenges: Design

How to Wire PCB mono input jack

In the design of modern electronic products, audio input and output are very important, especially in the design of audio equipment. As part of the audio equipment, the mono input

PCBA SMD preparation and processing considerations

PCBA chip processing is one of the core links in the manufacturing process of electronic products, which includes a number of stages from circuit design to product moulding. Each stage

What does ctr stand for on a pcb

What does ctr stand for on a pcb? The current transfer ratio (CTR) is a critical parameter in electronic design and component selection, especially in optocouplers, where CTR not only

Can you use ac in a pcb

Can you use ac in a pcb? Circuit boards can use either AC or DC as a power source, depending on the design and purpose of the board. Some circuit

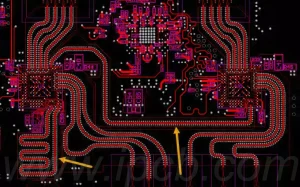

PCB pad types and their design guidelines

In PCB design,pads as a bridge connecting components and circuit boards, its type and design standards are critical. Different types of pcb pads are suitable for different components and application

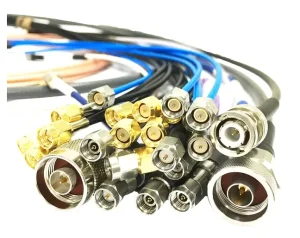

Is RF Assembly High Frequency or Low Frequency?

In modern communications and electronic technology, RF components play a vital role. However, many people still have doubts about the characteristics and operating frequency of RF components: Is RF assembly

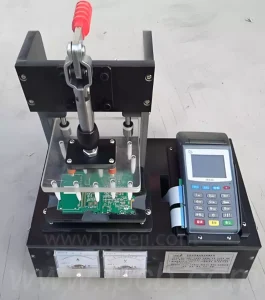

ate in pcba testing

Ate in pcba testing means testing the electrical conductivity and input-output values of the PCBA circuit board with mounted electronic components. In the design of the PCB circuit board, there

Key Insights into Circuit Card Assembly

In modern electronic devices, circuit card assembly are a core part that carries signal transmission, data processing and various control functions. Whether in smartphones, computers, or industrial automation equipment, circuit

Introduction of PCB radar

PCB radar is a circuit board specially designed for use in radar systems to connect and support various electronic components and devices in the radar system. It plays a key

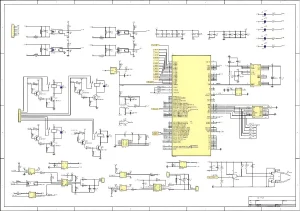

What is Schematic Diagram of PCB

In the modern electronics industry, schematic diagram of pcb are an indispensable and important part of the circuit design and manufacturing process. Whether you are a professional engineer or an

printed wiring board manufacturing process

Today we are going to explain the printed wiring board manufacturing process. If you are wondering, ” printed wiring board manufacturing process “, you have come to the right page.

The Future of Conformal Coating in Electronics

In the production and maintenance of modern electronic equipment, the protection of electronic components has always been an important issue. In particular, in the face of various harsh environmental conditions,

connector pcb edge

In the field of electronics, the connector pcb edge plays a vital role in establishing a reliable and secure connection with external devices. Whether you are working on a computer,

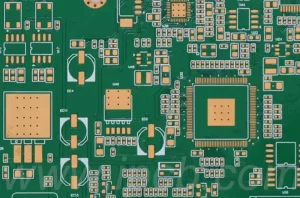

How to Identify Components on a Circuit Board

Circuit boards are an indispensable core part of modern electronic devices. They integrate various electronic components and realize various functions of the equipment through reasonable circuit design. However, for beginners,

Comprehensive Analysis of Quick Turn Printed Circuit Boards

With the rapid development of the electronics industry, the demand for printed circuit boards is also growing. In this efficient and precise market environment, “fast-turn printed circuit boards” has become