In the context of the PCB manufacturing industry’s upgrade towards high-end and miniaturization, HDI boards, with their unique technological architecture, have become the core carrier for solving the challenges of extremely small-sized circuit design. They not only meet the miniaturization demands of consumer electronics, medical devices, and automotive electronics but also propel PCB manufacturing technology towards higher precision and integration.

The core pain point of extremely small-sized circuit design lies in the dual contradiction of “space compression” and “performance assurance”: integrating more circuits and interconnect points into a limited board area while avoiding signal interference, transmission losses, and ensuring product reliability and mass producibility. Traditional PCBs rely on through-holes that penetrate the entire substrate, featuring large hole diameters and wide trace spacing, often failing to break through size limitations. In contrast, HDI boards achieve a balance between “small size” and “high performance” through four key technological innovations, making them the only preferred solution for extremely small-sized circuit design.

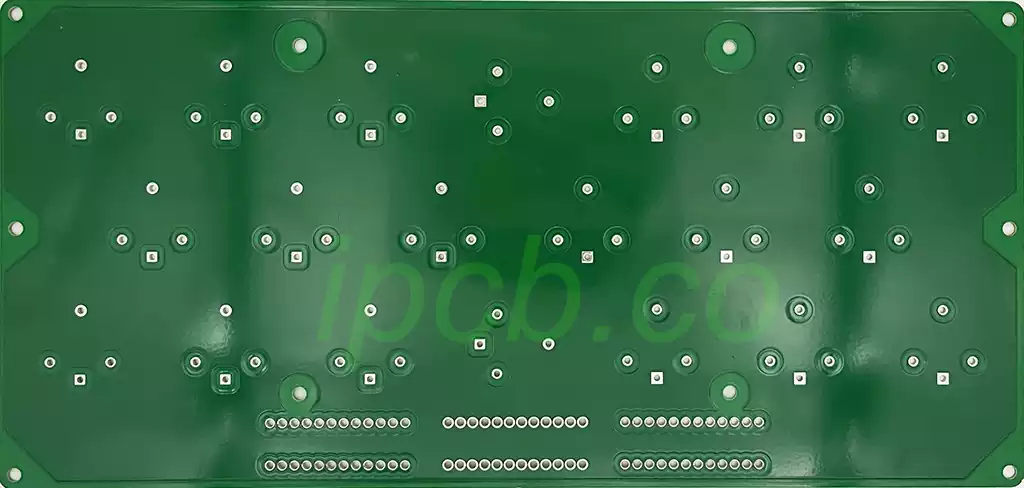

The key to HDI boards’ extremely small-sized design lies in breaking the design limitations of traditional PCB through-holes. They reconstruct circuit interconnectivity using microvias and buried vias, fundamentally reducing board area occupation. Traditional PCB through-holes need to penetrate the entire substrate, typically with a hole diameter of no less than 0.3mm, leaving “via stubs” on each board layer that occupy over 30% of the trace area, directly limiting circuit miniaturization layouts.

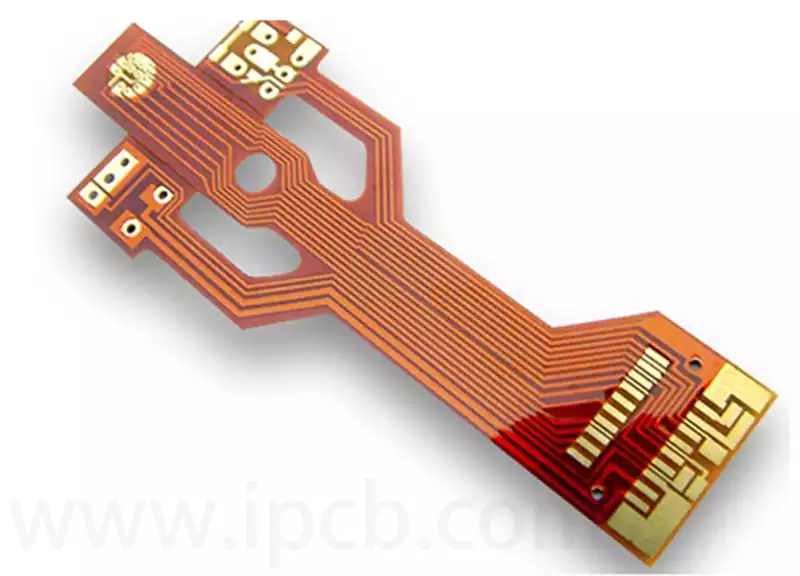

HDI boards, on the other hand, employ laser drilling technology to compress microvia diameters to 0.05mm (just 1/16th of a hair strand), with hole position accuracy controlled within ±0.01mm. Through the build-up process of “sequential lamination + laser drilling,” they achieve direct interconnectivity between any layers. Microvias only penetrate the surface layer and specified inner layers without traversing the entire substrate, acting like “non-penetrating deep wells” that complete signal transmission without occupying excess board area. Buried vias, completely hidden within inner layers and not connected to the surface layer, act like “underground tunnels” specifically addressing inner-layer circuit interconnectivity issues and completely avoiding occupation of surface-layer trace space.

The density of circuit traces directly determines the size of PCBs, and HDI boards’ trace process upgrades push line width and spacing to new limits, making “extremely small size” possible. Traditional PCBs, limited by dry film exposure processes, typically achieve line width and spacing of 75/75μm, with relatively low trace density, unable to accommodate a large number of circuits in small spaces.

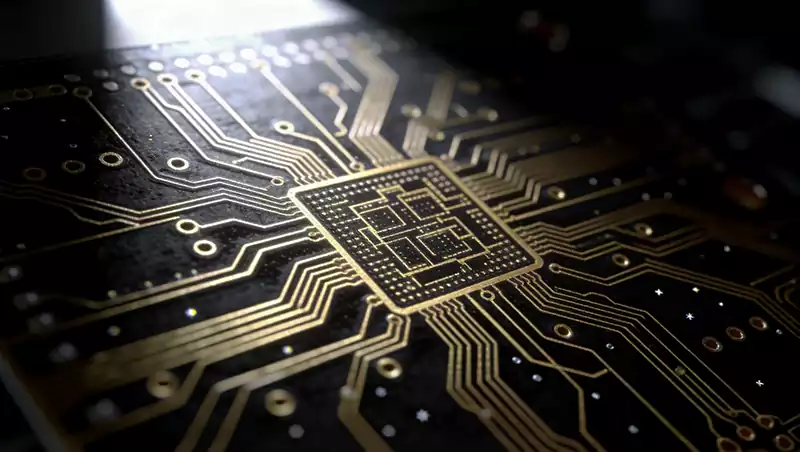

HDI boards, relying on laser direct imaging (LDI) technology combined with ultra-thin dry films (just 5μm thick), achieve line width and spacing of 30/30μm, with high-end HDI boards even reaching 20/20μm, equivalent to the width of two hair strands placed side by side. This fine-pitch trace process not only significantly increases trace density but also optimizes trace routing through three-dimensional electromagnetic field simulation design, avoiding signal crosstalk and transmission losses while compressing size. For example, in 5G high-frequency scenarios, fine-pitch traces can reduce signal attenuation by over 15%, ensuring stable performance of extremely small-sized circuits.

More critically, HDI boards’ trace process enables “layered tracing and arbitrary interconnectivity,” allowing circuits with different functions to be laid out in separate layers, avoiding congestion in same-layer tracing and further compressing board area.

Extremely small-sized circuit design imposes extremely stringent requirements on PCB materials—they must not only adapt to the processing precision of fine traces and microvias but also ensure signal integrity, resistance to environmental interference, and avoid circuit deformation caused by material thermal expansion and contraction. HDI boards abandon traditional PCB universal materials and select materials precisely based on application scenarios, laying a solid foundation for extremely small-sized design.

In the consumer electronics sector, HDI boards often choose LCP (Liquid Crystal Polymer) film materials, with a Z-axis coefficient of thermal expansion (CTE) matching 90% with solder joints, effectively avoiding circuit deformation in high-temperature environments while controlling water absorption rates below 0.08%, ensuring stable performance in humid environments. In high-frequency communication and automotive electronics sectors, they select PTFE low-loss substrates or high-Tg substrates (Tg ≥ 170°C). PTFE substrates have a stable dielectric constant around 2.2, reducing high-frequency signal attenuation, while high-Tg substrates can withstand engine compartment temperatures of 85°C, avoiding circuit failures caused by material softening. In medical implant device sectors, HDI boards choose biocompatible, volume-stable polyimide substrates to ensure long-term stable operation within the human body.

Additionally, HDI boards use ultra-thin electrolytic copper foils (thickness below 12μm), which not only adapt to the etching process of fine-pitch traces but also reduce the space occupied by copper foils, further compressing board area while ensuring circuit conductivity. This “material-design adaptation” approach enables HDI boards to meet performance demands in various scenarios despite their extremely small size.

The precision requirements for extremely small-sized circuit design are almost exacting, with even a 0.01mm deviation potentially causing circuit shorts or signal failures. HDI boards, however, control deviations within reasonable ranges through full-process digital precision management, ensuring technology implementation and mass production feasibility.

During the design phase, three-dimensional simulation software is used to preemptively avoid trace conflicts, hole position deviations, and other issues, ensuring the rationality of design solutions. In the production phase, laser drilling machines employ dual-camera vision positioning with a repeatability accuracy of ±1.5μm, and femtosecond laser pulses precisely control drilling depth and diameter. Electroplating production lines are equipped with X-ray thickness gauges to adjust current density in real-time, ensuring copper layer thickness uniformity deviations of less than 3%. During the inspection phase, CT scanning technology and laser vision inspection are used to precisely detect microvia wall quality and line width/spacing deviations, eliminating product failures caused by minor flaws. This full-process precision management enables HDI boards’ extremely small-sized design to transition from “laboratory technology” to “mass production.”

From the ultimate thinness of consumer electronics to the miniature implantation of medical devices and the high-density integration of automotive electronics, HDI boards, through comprehensive innovations in via technology, tracing, materials, and inspection, continuously push the limits of extremely small-sized circuit design, becoming the core support for the PCB manufacturing industry’s upgrade towards high-end development.

In the future, with the development of heterogeneous integration technology, the technological boundaries between HDI boards and IC substrates will gradually blur, further compressing size and enhancing performance, unlocking more possibilities for extremely small-sized circuit design and empowering innovation across various industries.