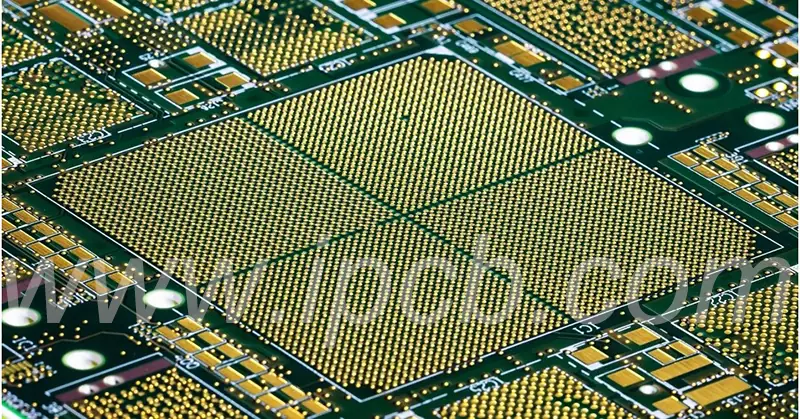

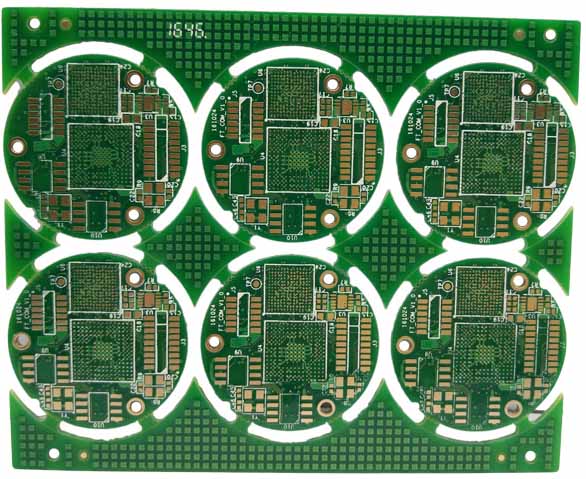

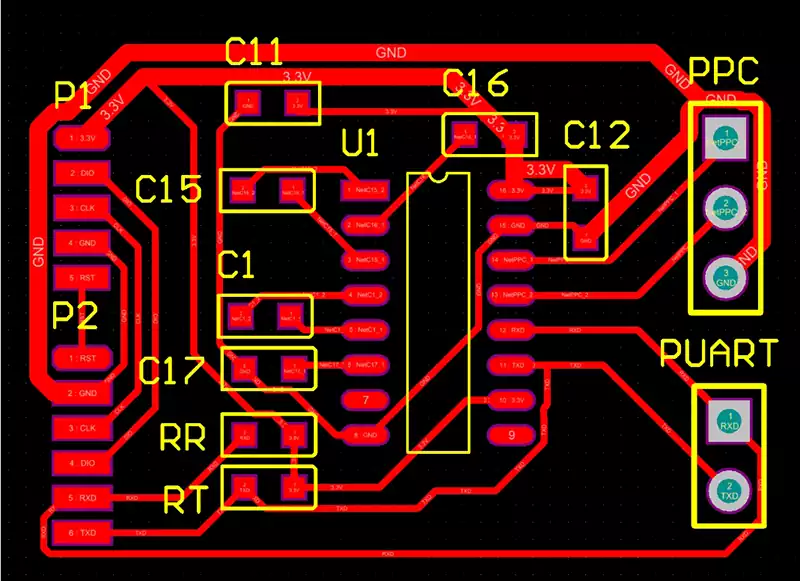

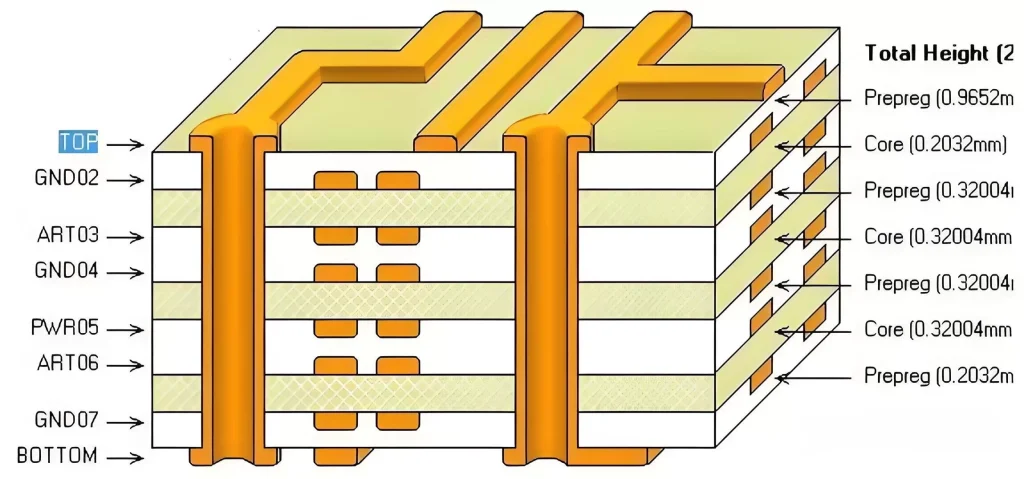

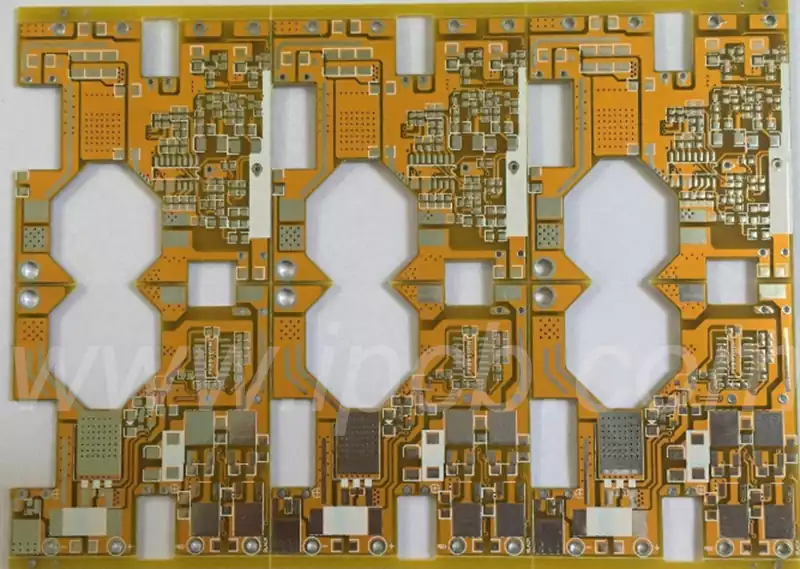

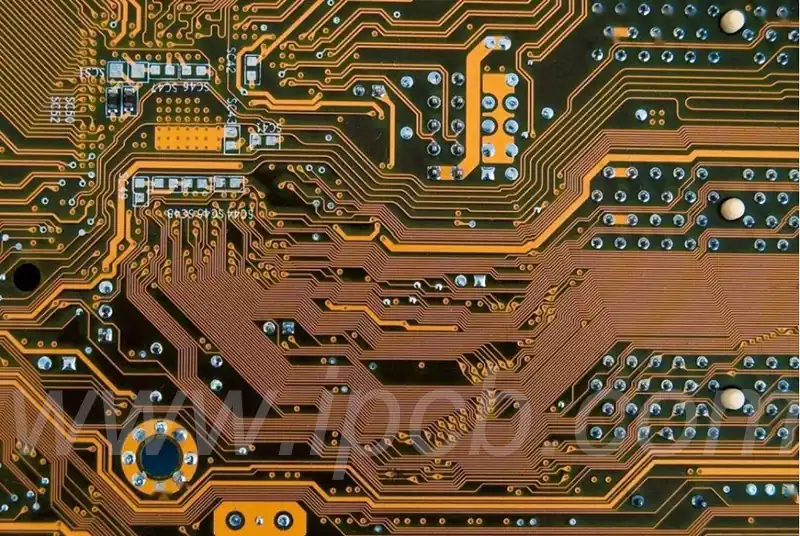

teflon pcb laminate

The use of teflon pcb laminate has increased dramatically recently. There are many reasons for this change. One of the reasons is the rapid development of the electronics industry and the increasing demand for high-frequency boards.What is teflon pcb laminateTeflon is a chemical substance that can be simply called polytetrafluoroethylene or PTFE. It is widely […]