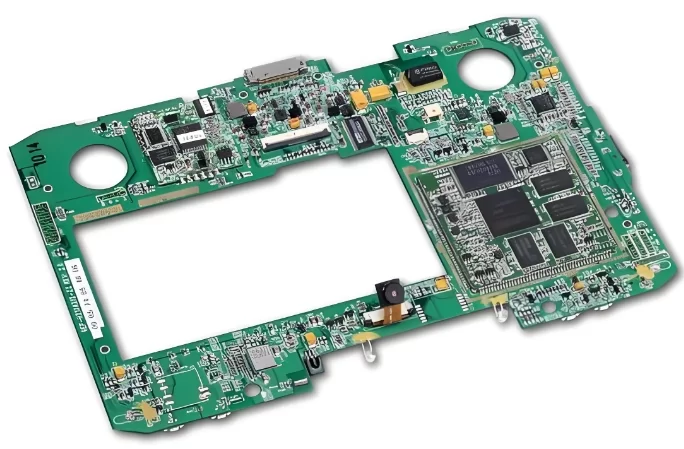

What is RoHS PCB Board

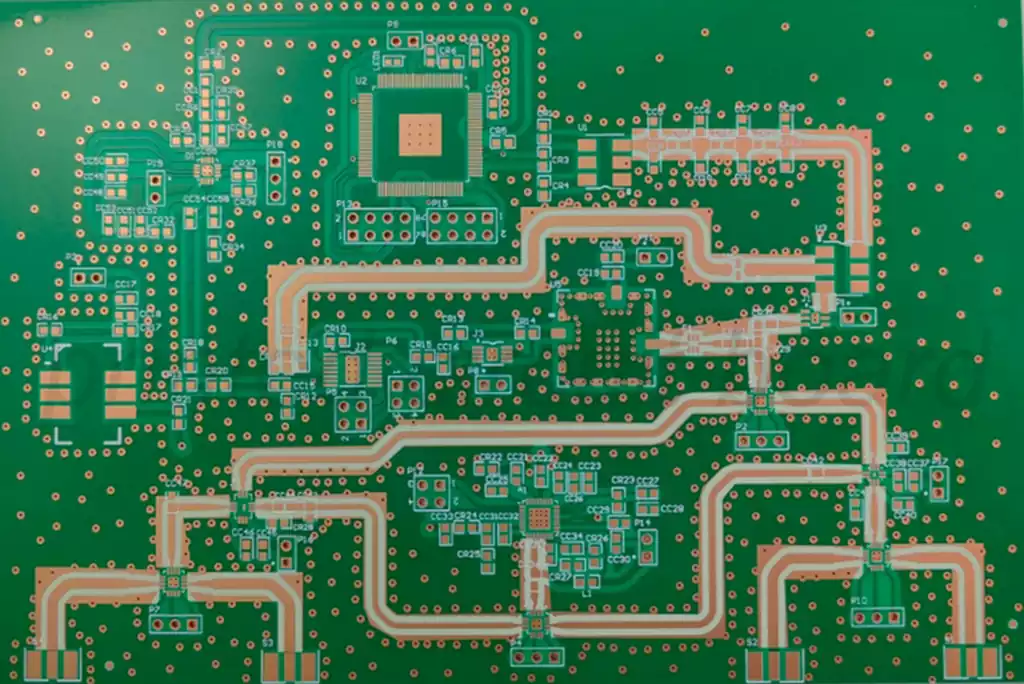

Printed circuit boards (PCBs) are the foundation of modern electronics, and their manufacture involves a wide range of materials and chemicals. However, as environmental awareness grows, global requirements for PCB production are becoming “greener” to minimize harm to the environment and human health. RoHS compliant PCBs have emerged to not only meet the strict environmental […]