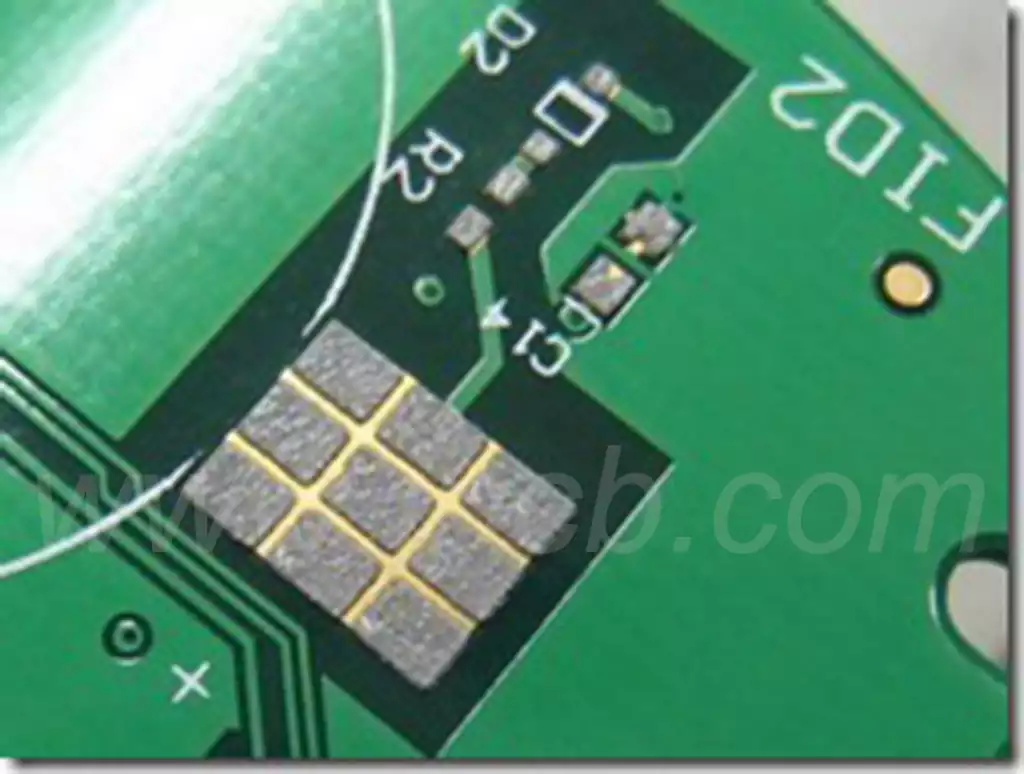

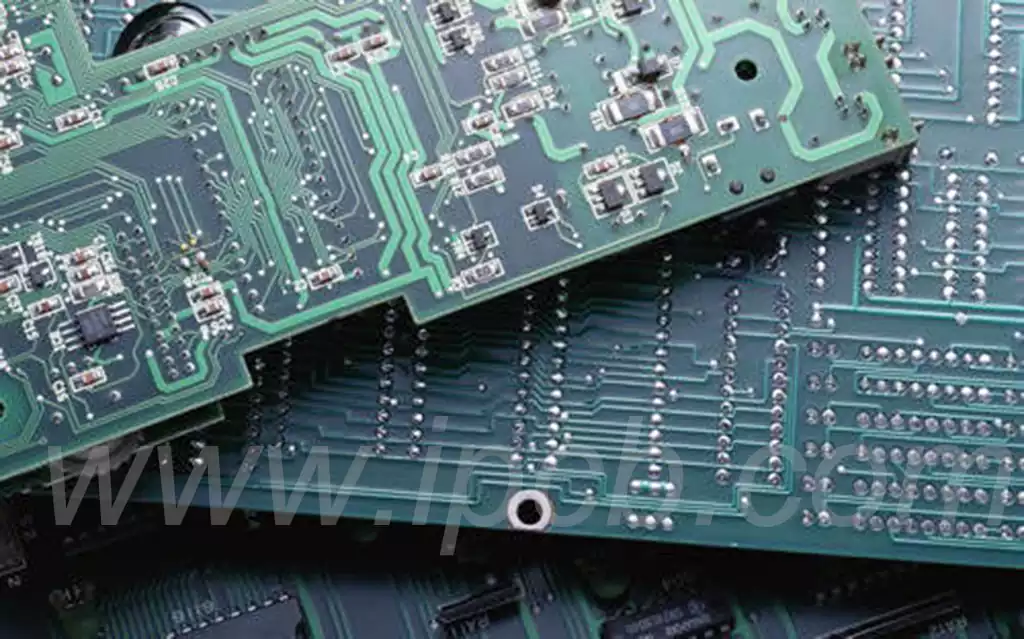

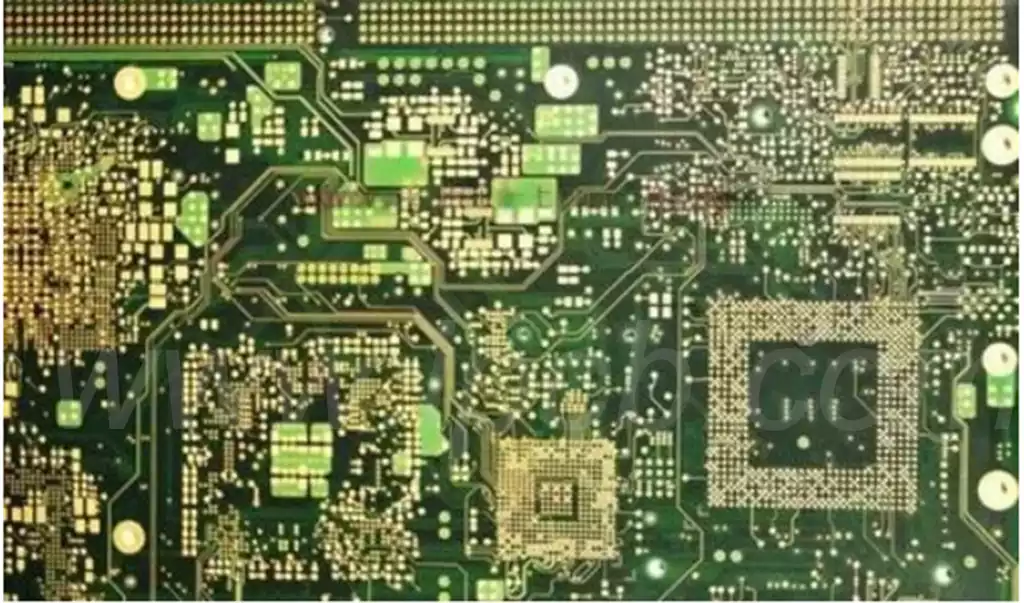

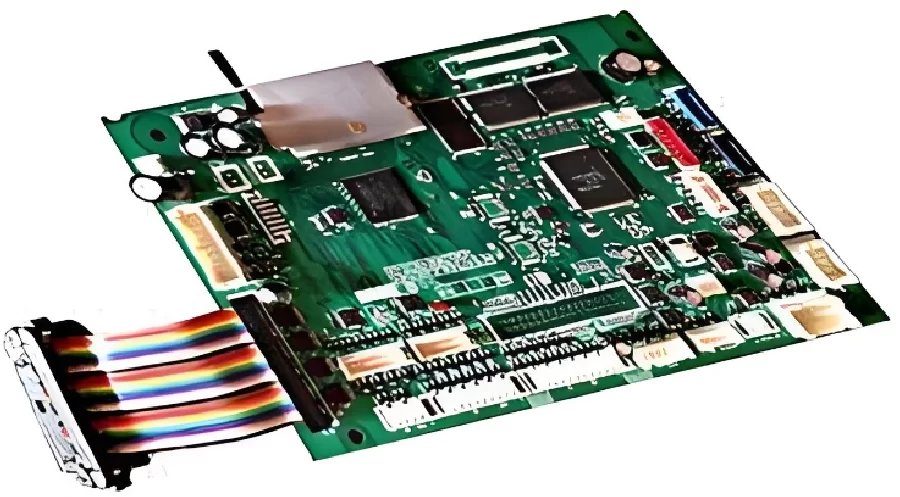

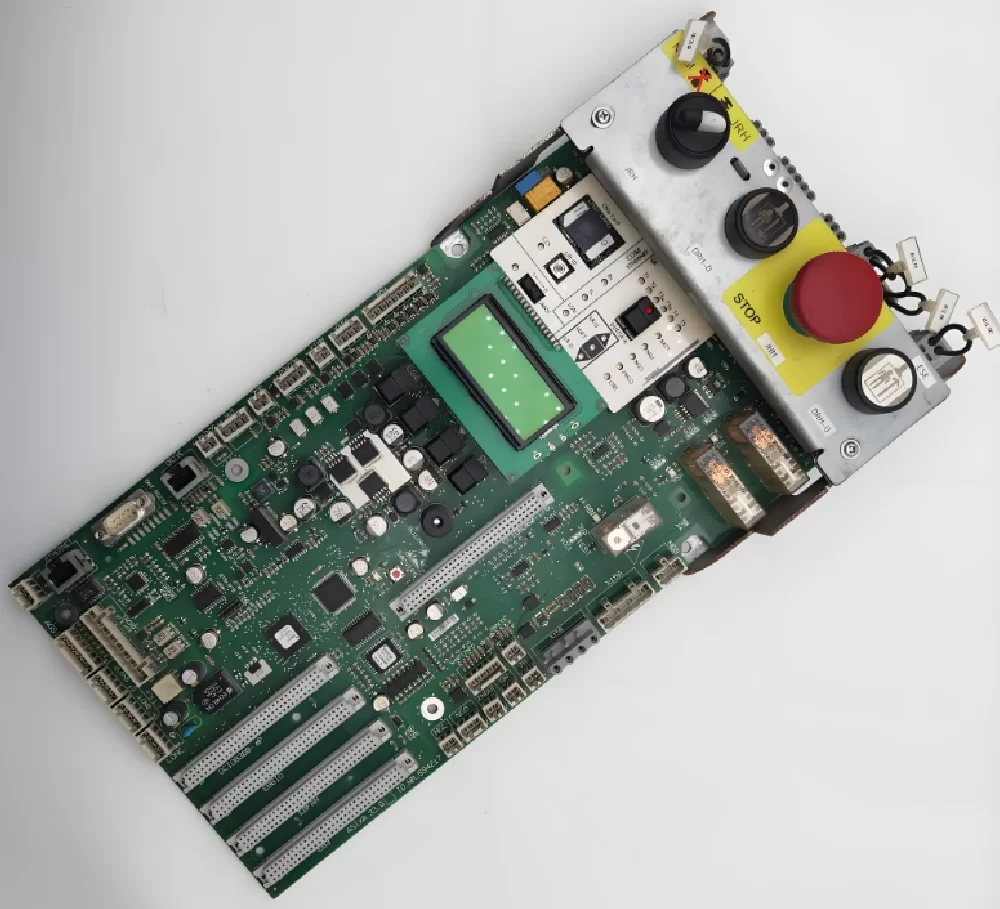

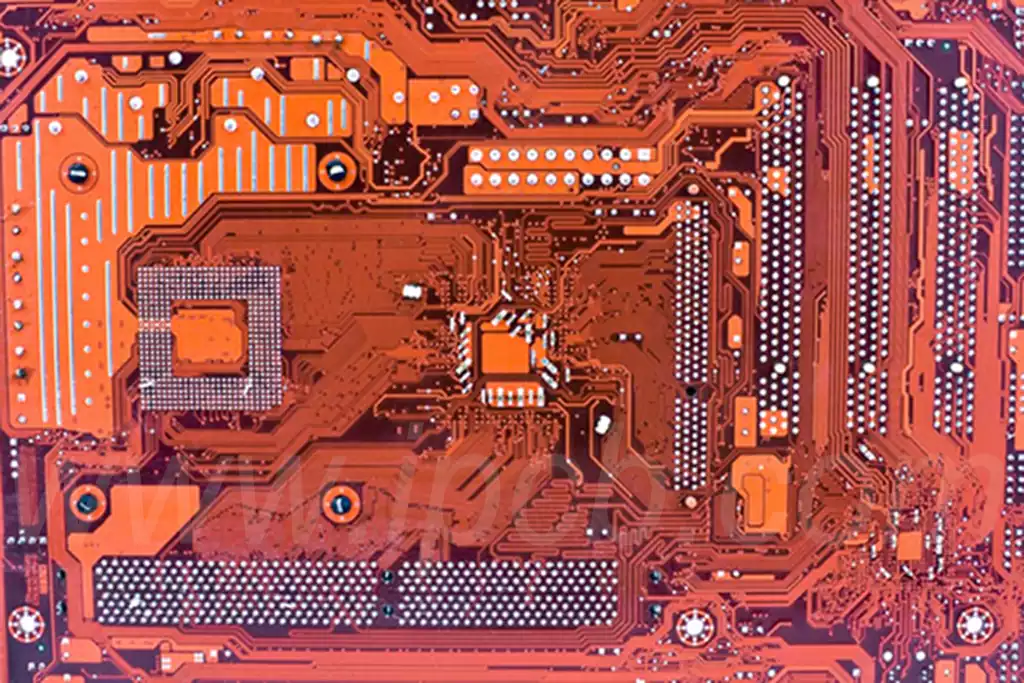

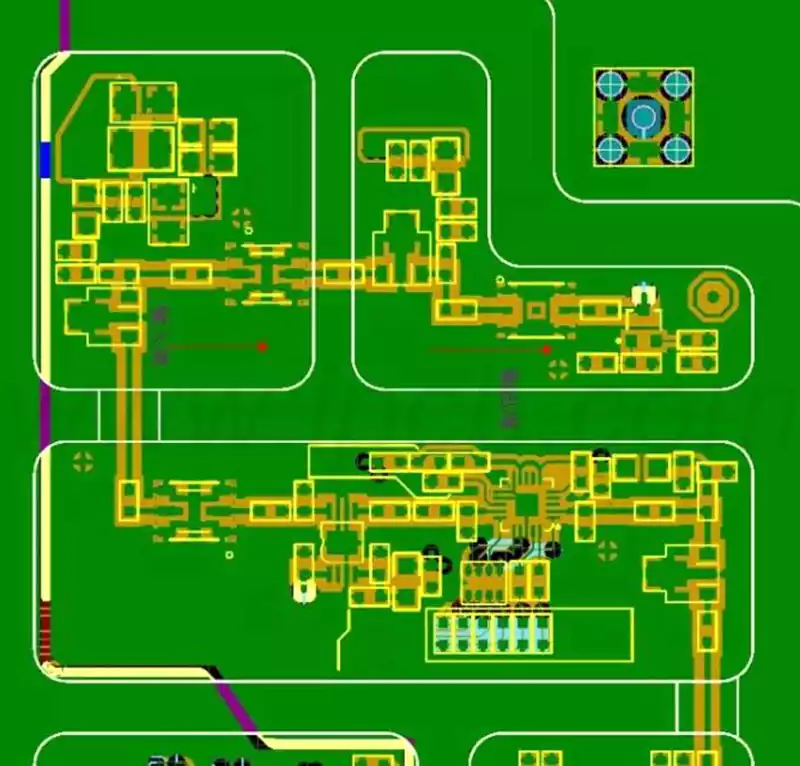

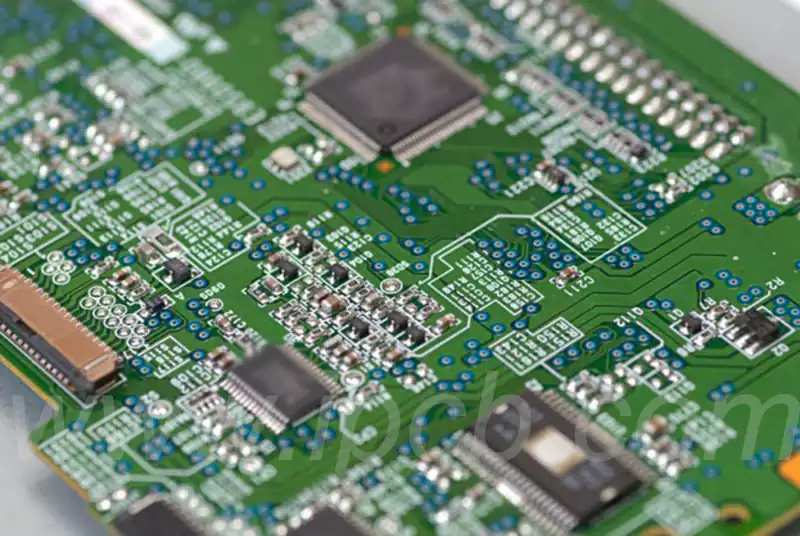

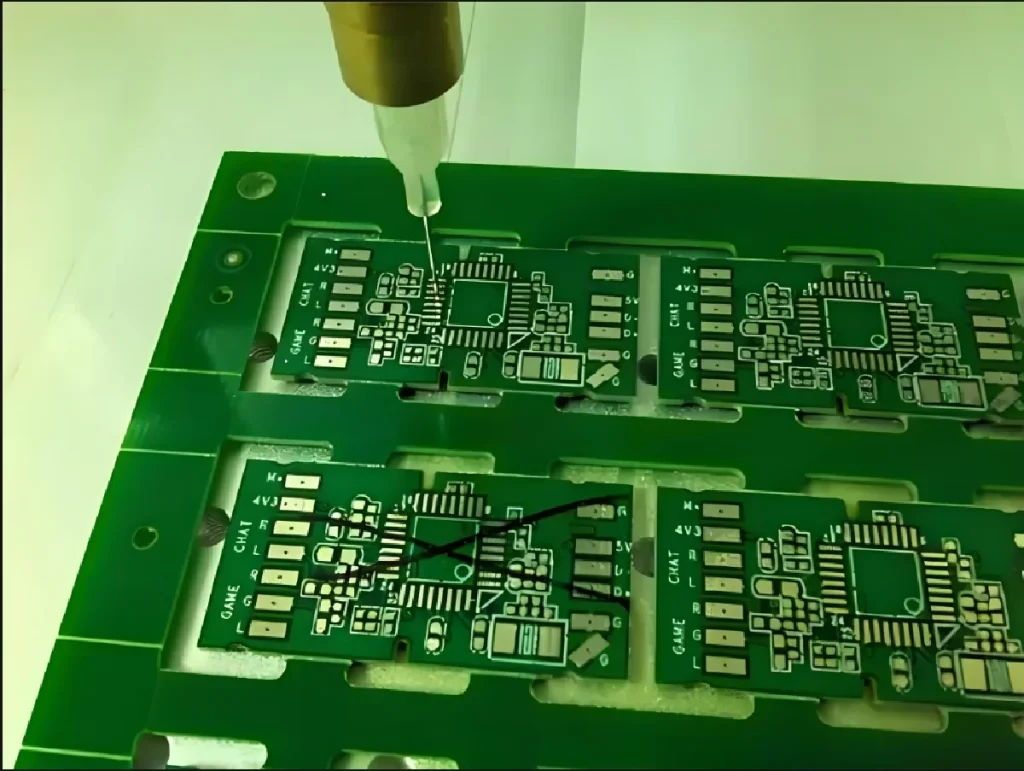

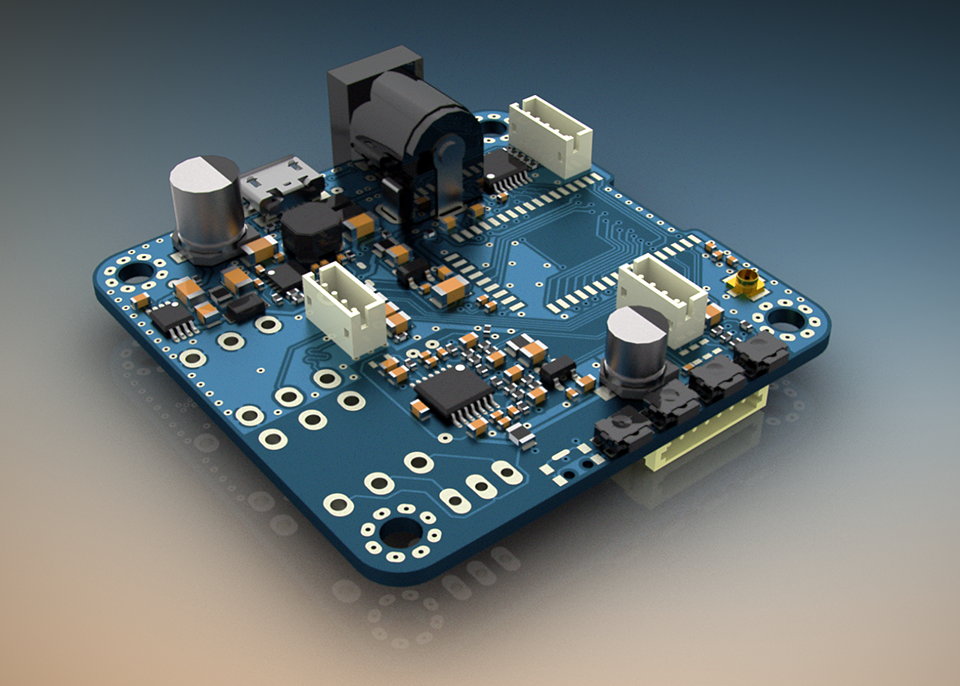

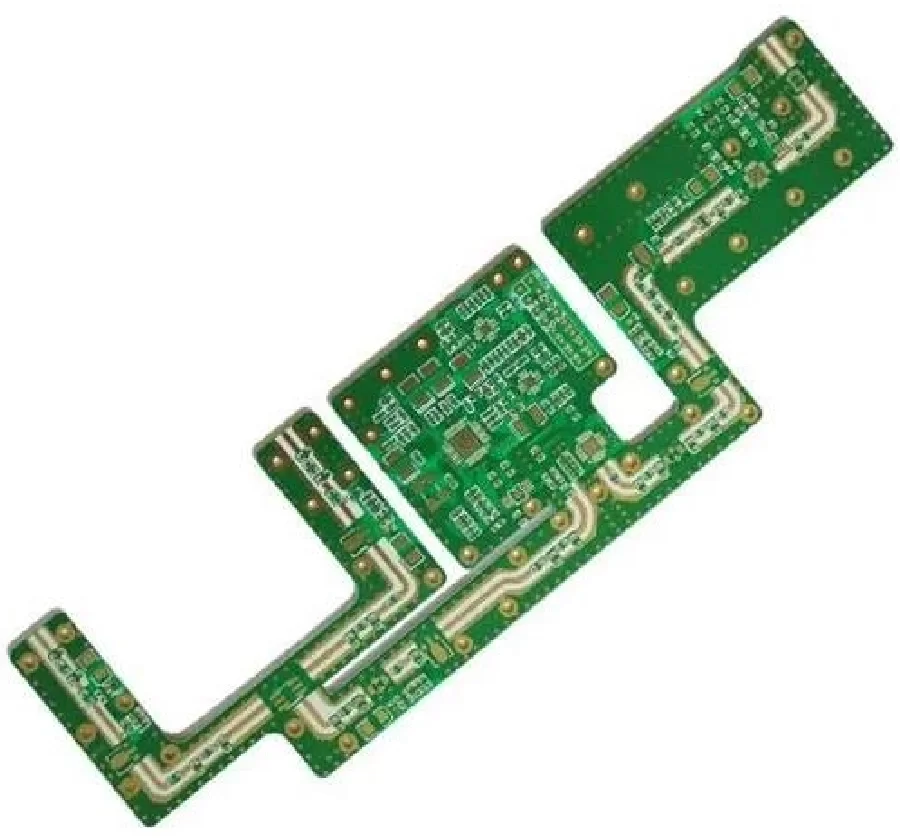

Chip on board ic technology

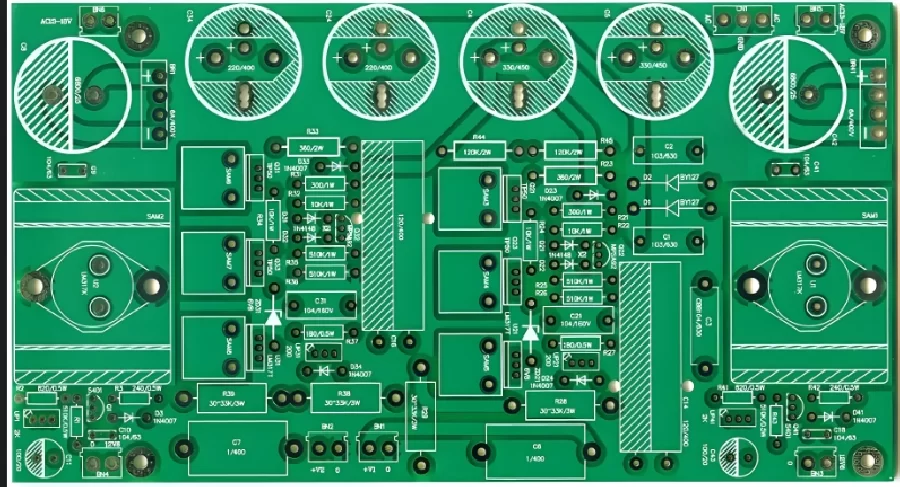

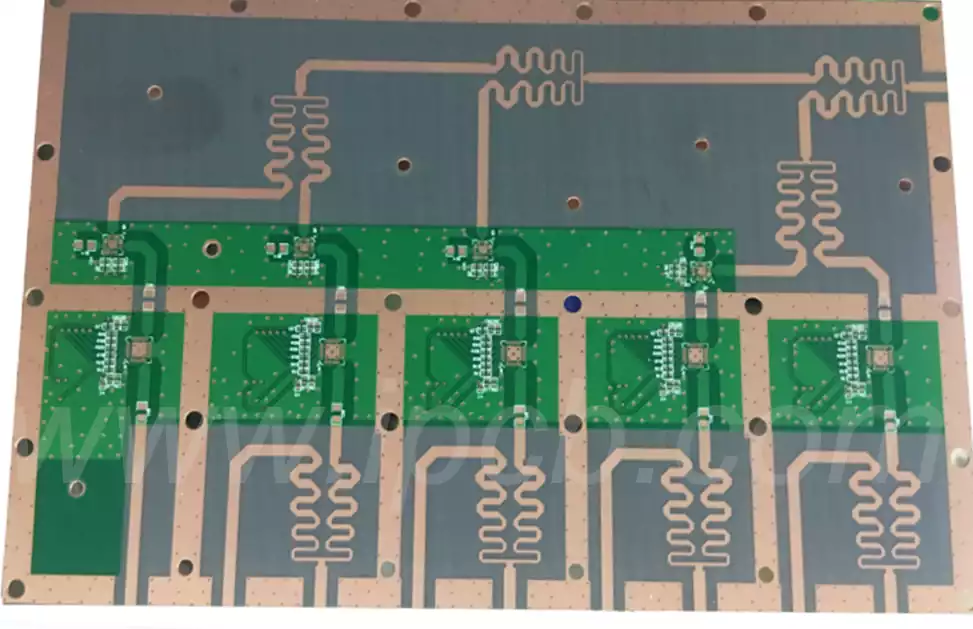

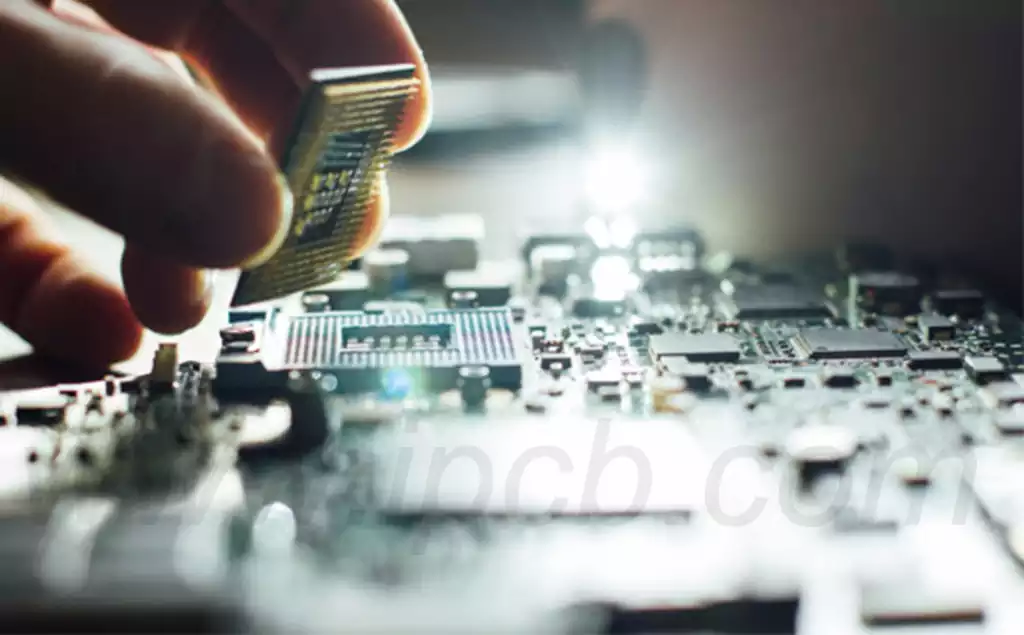

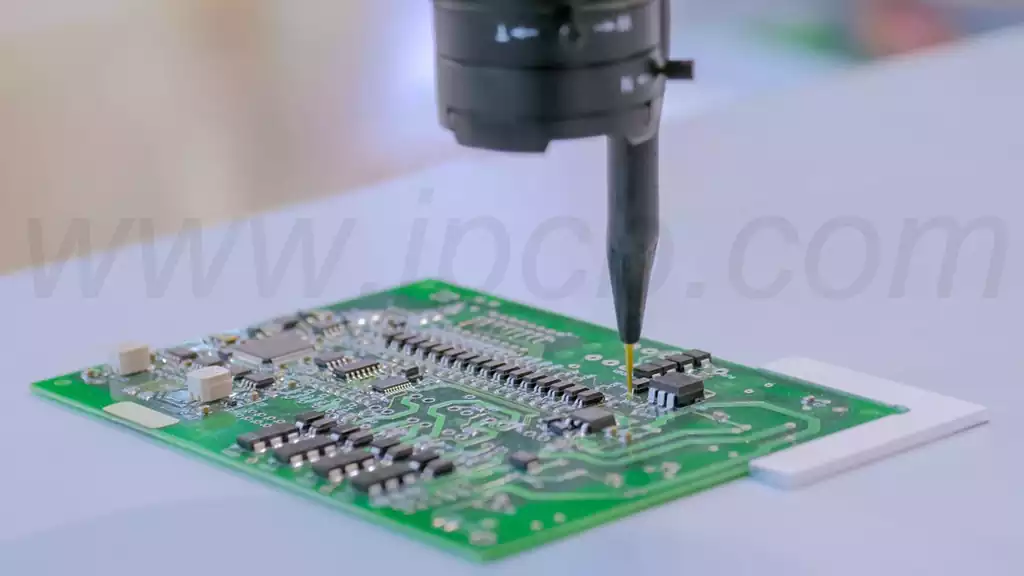

Chip on board ic refers to a system formed by pasting a chip directly onto a circuit board, usually in an unpackaged or simplified package.This technology allows electronic components to be more tightly connected to the circuit board, which significantly improves the efficiency of space utilization and the overall performance of the system. The use […]