The impact of graphics card pcb layer count on performance

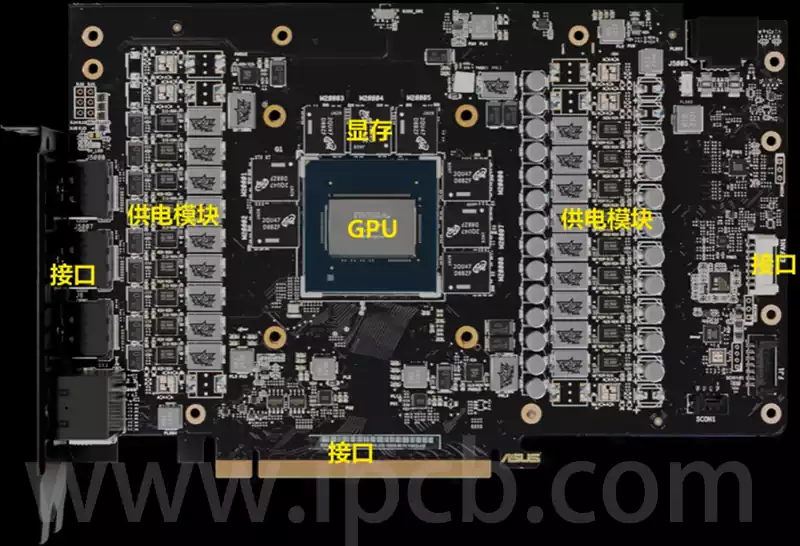

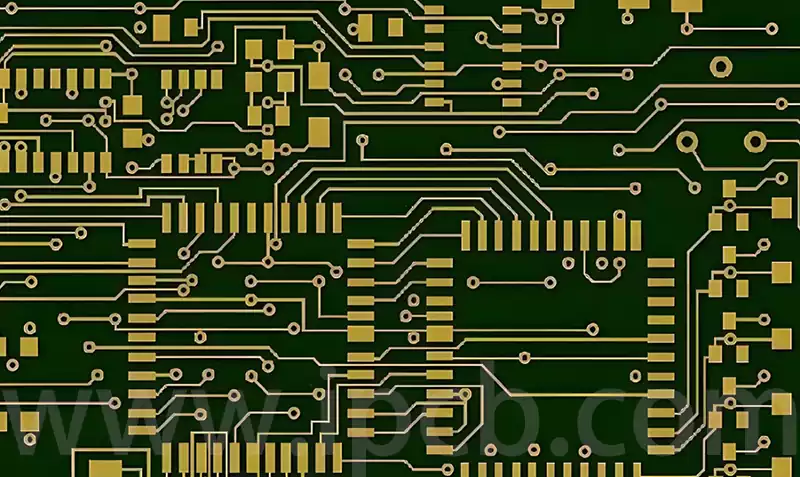

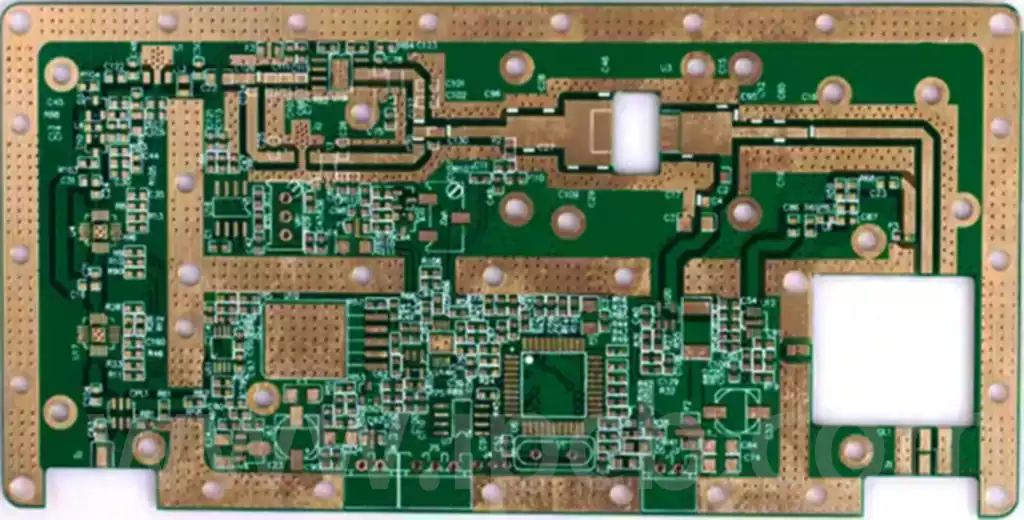

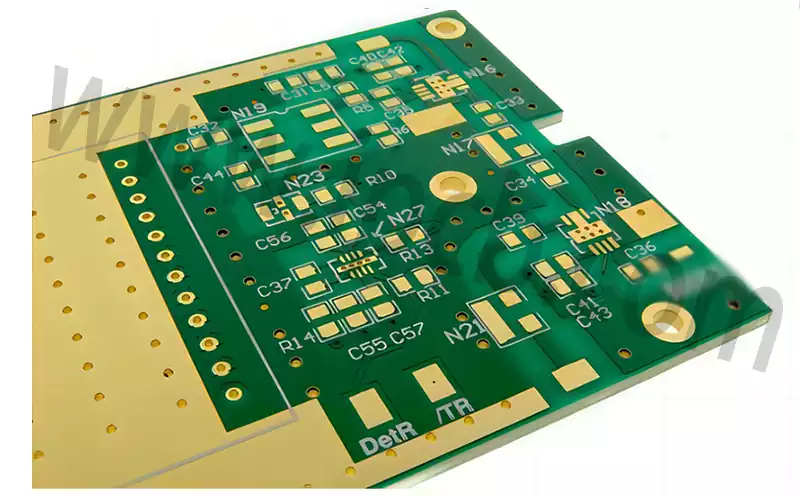

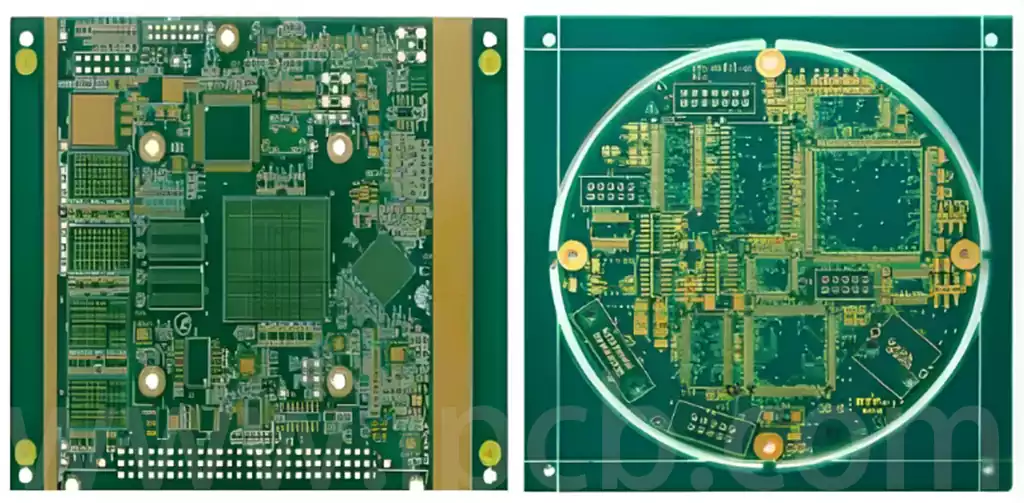

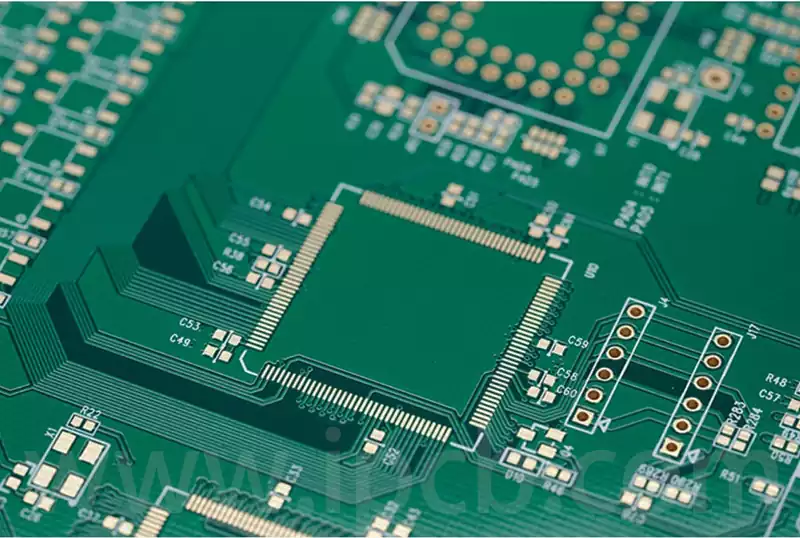

A graphics card circuit board, also known as a graphics card motherboard or graphics card PCB, is a circuit board used to transmit signals from the graphics processing unit (GPU). It is a very important component inside a computer, working in conjunction with the CPU and memory to ensure that the computer can handle high-load […]