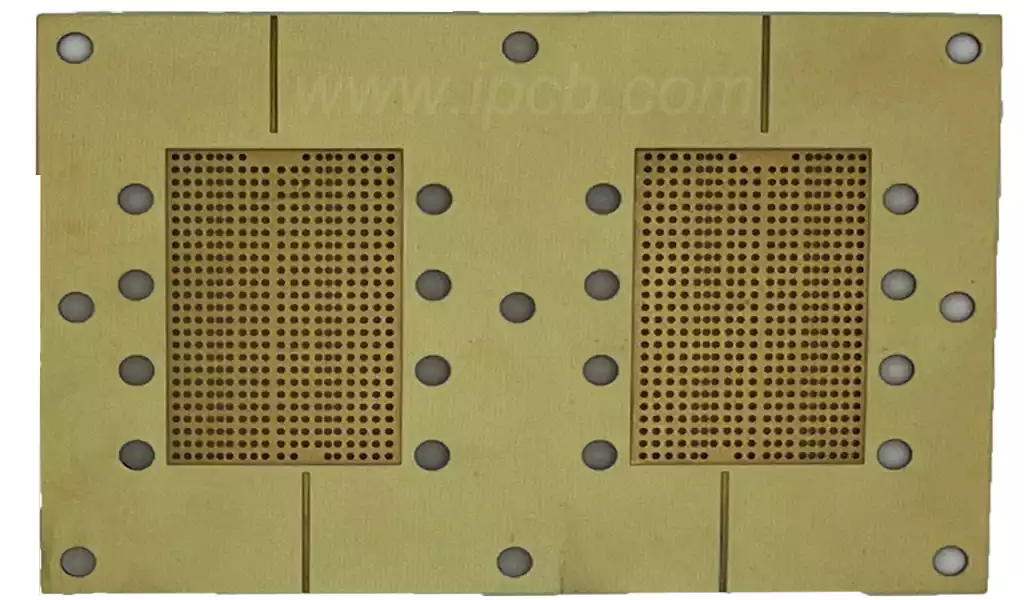

A concave cavity PCB is a high-performance circuit board designed with a concave structure. By forming a concave space within the circuit board, space can be utilized more efficiently to promote miniaturization and integration of electronic devices. It makes full use of the internal space of multilayer circuit boards in the manufacturing process and can place components such as resistors, microcontrollers, heat sinks, etc. in the concave cavities to achieve high-density integration.

There are significant differences between the design and application of a cavity PCB and a normal circuit board.

A concave circuit board is a circuit board designed with a concave structure, which allows the board to achieve a higher level of integration and a smaller size. In contrast, normal circuit boards are usually more conventional in design, less integrated, and larger. Second, it is usually used in highly integrated, high-performance electronic devices, such as mobile communications, satellite communications, avionics, and other fields. In contrast, ordinary circuit boards are widely used in a variety of electronic devices, but their integration and performance is relatively low. In addition, the manufacturing process is different from that of ordinary circuit boards. The manufacturing of concave circuit boards requires the use of special processes and technologies, such as the use of internal space in multilayer circuit boards, precision component placement, and soldering. In contrast, the manufacturing process for ordinary circuit boards is relatively simple and usually utilizes a single or dual-panel design.

Technical advantages:

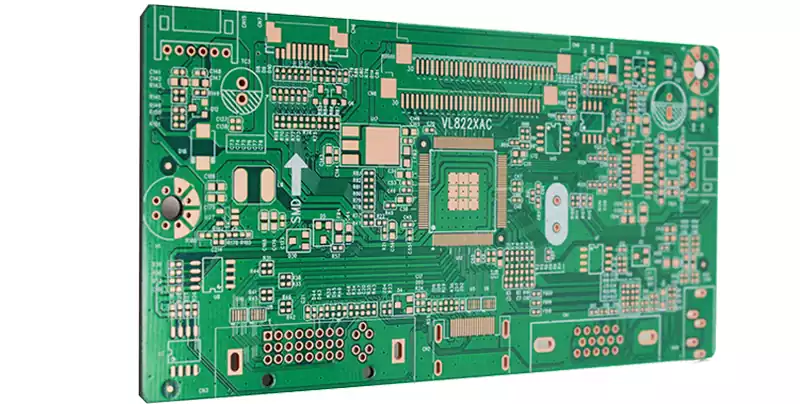

High Integration: Cavity PCB is designed with a concave structure that makes full use of space and achieves a high level of integration. This allows electronic components to be arranged in a more compact manner, which improves the utilization of the circuit board and makes electronic equipment thinner and more compact.

Efficient Heat Dissipation: The concave structure design helps airflow and enhances heat dissipation, which effectively reduces the working temperature of electronic components and ensures the stable operation of the equipment. This is especially important for high-power electronic devices.

Enhanced electromagnetic shielding: The concave structure can enhance the electromagnetic shielding effect to a certain extent, reduce electromagnetic interference, and improve the electromagnetic compatibility of the equipment. This is an important advantage for electronic equipment that requires high reliability.

Improve the quality of signal transmission: its design can reduce the loss during signal transmission and improve the quality of signal transmission. This is very beneficial for electronic devices that require high-speed signal transmission. The design of cavity PCB makes it easier to place and solder electronic components, as well as facilitating future maintenance and repair.

Material Requirements:

Insulation: The material is required to have good insulation to ensure that the signal transmission between electronic components will not cause short circuit boards or leakage phenomena. Therefore, the material should have high insulation resistance and voltage resistance.

Stability: The manufacturing and use of the process will experience many temperature changes and mechanical stress, the material is required to have good thermal and mechanical stability to maintain the performance and dimensional stability of the circuit board.

Corrosion resistance: the manufacturing process will come into contact with a variety of chemicals, the material is required to have good corrosion resistance to prevent chemical damage to the circuit board.

Processability: Manufacturing involves complex machining processes, requiring materials with good processability, such as easy to cut, drill, and bend.

Dimensional accuracy: Higher requirements for dimensional accuracy require good dimensional stability of the material to ensure the accuracy and reliability of the circuit board.

Lightweight: concave cavity circuit boards are usually used in mobile devices and aircraft and other occasions that require weight reduction, requiring materials with lightweight, low-density characteristics.

Environmental protection: modern electronic products are increasingly focusing on environmental protection, requiring materials with recyclability and non-toxicity characteristics, to reduce the pollution of the environment.

Application Scenarios:

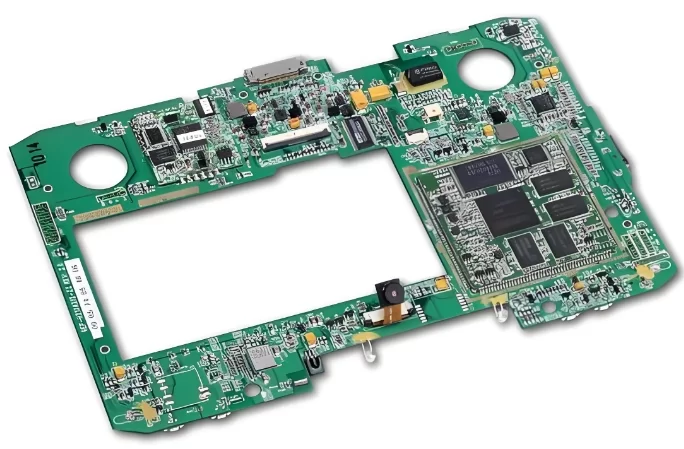

Mobile communication: mobile devices such as cell phones, tablet PCs and other mobile devices have increasingly high requirements for thinness and high performance, and concave cavity pcb has become a key technology to achieve this goal.

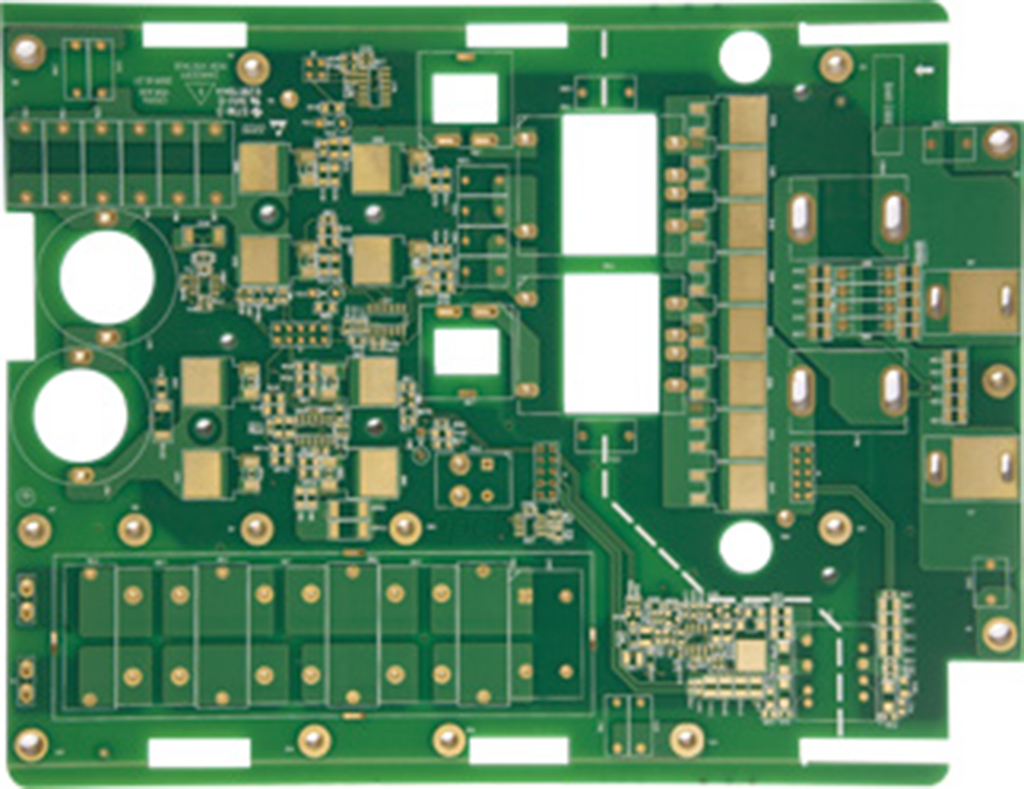

Satellite communications: In the field of satellite communications, lightweight and miniaturization of equipment is particularly important due to the special characteristics of the space environment. It provides strong support for the design of satellite communication equipment.

Avionics: The control systems of airplanes, drones, and other aircraft require highly integrated, high-performance pcb boards. It can meet these stringent requirements and enhance the overall performance of avionics systems.

Medical Devices: Medical devices have extremely high requirements for precision and stability. Due to its advantages of high-density integration and miniaturization, it is widely used in the manufacture of medical equipment.

Military electronics: In the military field, high-performance, lightweight electronic equipment is vital to improving the combat effectiveness and mobility of weapons and equipment. It provides strong support for the development of military electronics technology.

Embedded system: In the field of smart home and smart manufacturing, embedded systems are playing an increasingly important role. Concave cavity circuit boards provide solutions for miniaturization and high performance of embedded systems.

Automotive electronics: With the development of automotive intelligence, the complexity of automotive electronic systems is increasing. It has a wide range of application prospects in the field of automotive engine control, safety systems, and so on.

Internet of Things (IoT) devices: The popularity of IoT devices puts higher requirements on the integration and stability of circuit boards. With its high-density integration and efficient heat dissipation, it has become the preferred solution in the manufacturing of IoT devices.

As an innovative technology, cavity PCB is gradually penetrating various high-tech fields, helping electronic equipment to achieve the goal of lighter, thinner and higher performance. With the continuous progress of technology and the expansion of application scenarios, concave circuit boards will continue to lead the trend of electronic equipment innovation. iPCB is a PCB manufacturer that offers a wide range of PCB from well-known brands and prepares enough boards to meet your quick needs. to meet your quick needs.