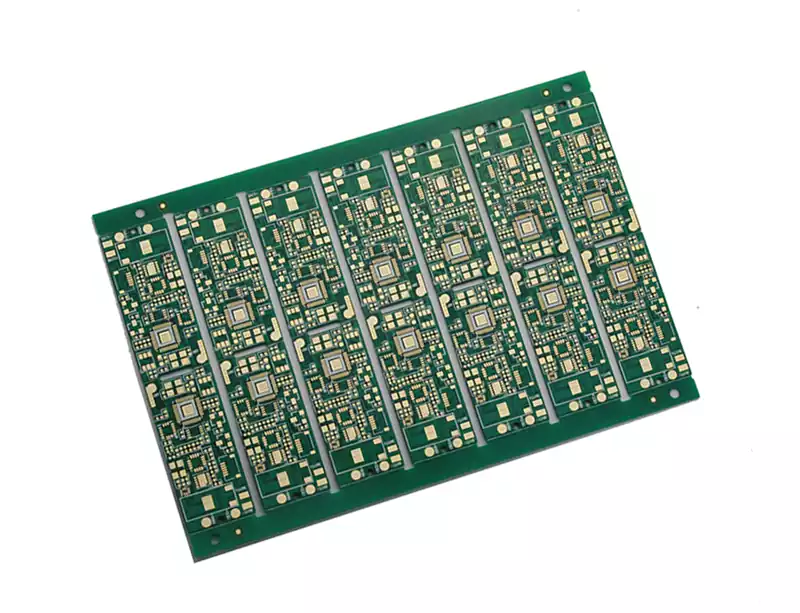

Within the vast realm of electronic circuits, the printed circuit board (PCB) plays an indispensable role. It serves as both the solid foundation and vital link for electronic components, providing structural support and enabling electrical connections. Its performance, much like the foundations of a building, directly determines the overall quality and reliability of the electronic product. Among the numerous circuit board types, ceramic circuit boards and standard circuit boards are two of the most prevalent. They exhibit distinct and noteworthy differences across multiple dimensions, including material composition, performance characteristics, manufacturing processes, application scenarios, and respective advantages and disadvantages.

Differences in Material Composition

Standard circuit boards are typically constructed by bonding copper foil to a substrate. Substrate materials vary, with fibreglass (FR-4) and phenolic resin (FR-3) being the most prevalent, though some utilise ceramic substrates. Bonding agents commonly employ phenolic or epoxy resins. This material combination adequately meets basic requirements in conventional electronic applications, yet its performance may be constrained in certain specialised environments.

Ceramic circuit boards, conversely, employ a bonding process under high temperatures to tightly integrate copper foil with a ceramic substrate. This unique bonding method creates an exceptionally strong union between the copper foil and ceramic substrate, effectively preventing copper foil delamination and providing robust assurance for the board’s reliability.

Performance Comparison

Thermal Conductivity

Thermal conductivity is a key indicator of circuit board quality. Standard glass fibre-based boards exhibit relatively limited heat dissipation capabilities. During prolonged high-load operation of electronic devices, heat readily accumulates within the board, causing component temperatures to rise and consequently impacting device performance and lifespan.

Ceramic circuit boards offer significant advantages in heat dissipation. Taking the common ceramic substrate material aluminium oxide (Al₂O₃) as an example, its thermal conductivity varies with purity but remains higher overall than that of standard glass fibre substrates. Aluminium nitride (AlN) ceramic substrates exhibit thermal conductivity 7 to 10 times that of aluminium oxide, enabling rapid conduction of heat generated by chips for highly efficient dissipation. This is crucial for equipment with stringent thermal management requirements, such as high-power power electronic modules, effectively preventing performance degradation and damage caused by overheating.

Current Carrying Capacity

Current carrying capacity directly determines the maximum current a circuit board can handle. Conventional boards tend to overheat when carrying substantial currents, limiting their use in high-power applications.

Ceramic circuit boards demonstrate exceptional current carrying capacity. Test data indicates that when 100A current flows continuously through a 1mm × 0.3mm thick copper layer, the temperature rise is approximately 17°C; whereas through a 2mm × 0.3mm thick copper layer, the temperature rise is only around 5°C. This outstanding current-carrying capacity enables ceramic circuit boards to readily meet the current demands of high-power electronic equipment, ensuring stable operation.

Insulation and Voltage Resistance

Insulation and voltage resistance are critical factors in ensuring the safe operation of electronic equipment. While conventional circuit boards meet the insulation and voltage resistance requirements for general electronic products, their performance may fall short of standards in applications demanding exceptionally high safety levels, such as aerospace and military electronics.

Ceramic circuit boards exhibit superior insulation and voltage resistance. Their insulation resistance and dielectric strength significantly exceed those of standard circuit boards, effectively preventing electrical faults like current leakage and short circuits. This provides reliable safeguards for both equipment and personnel safety.

Thermal Expansion Coefficient

Differences in thermal expansion coefficients induce thermal stresses in circuit boards during temperature fluctuations, thereby compromising dimensional stability and reliability. Conventional boards are prone to warping and deformation due to mismatched thermal expansion coefficients between the substrate and copper foil, adversely affecting component mounting and signal transmission.

Ceramic circuit boards exhibit a lower thermal expansion coefficient, with certain ceramic substrates (such as aluminium nitride) offering near-matching coefficients to silicon wafers. This ensures dimensional stability during thermal cycling, minimising warping and deformation. Consequently, ceramic boards excel in demanding applications requiring exceptional thermal stability, such as high-power semiconductor chips.

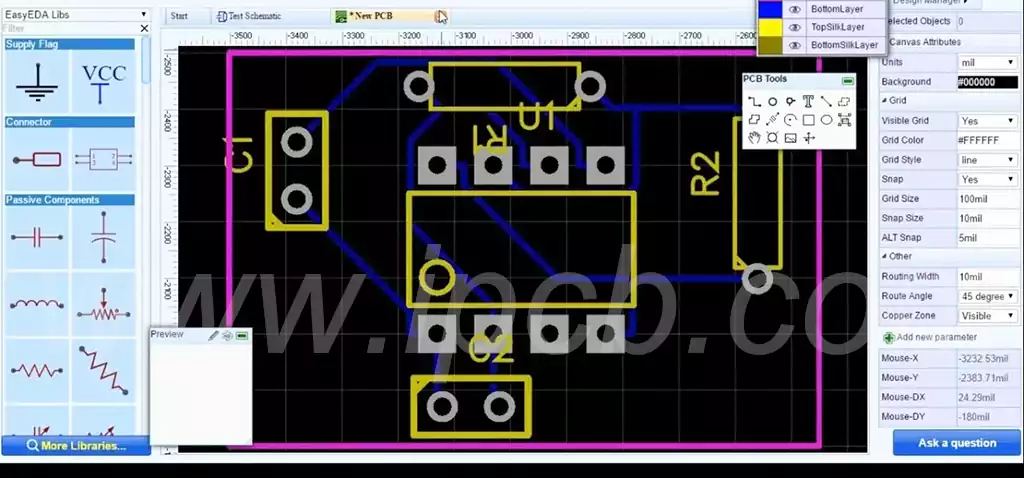

Production Process Comparison

Conventional circuit board manufacturing employs relatively mature techniques, yet remains susceptible to multiple factors during processing. Thermal stresses, chemical influences, improper production methods, or asymmetrical copper plating on both sides during design can readily cause varying degrees of warping. This not only compromises the board’s aesthetic quality but also adversely affects component mounting and circuit performance.

Ceramic circuit boards employ high-temperature bonding techniques to tightly integrate copper foil with ceramic substrates. This manufacturing process effectively prevents warping issues common in standard boards during processing, ensuring superior flatness and dimensional accuracy. Concurrently, the bonding technology enhances the adhesion between copper foil and ceramic substrate, significantly improving board reliability.

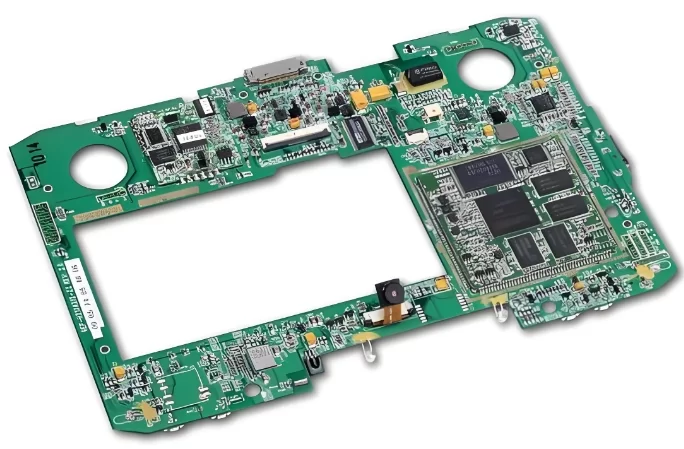

Differences in Application Scenarios

Given the aforementioned performance disparities, ceramic circuit boards and conventional circuit boards exhibit distinct application scenarios. Conventional circuit boards, owing to their lower cost and mature production processes, are widely employed in various consumer electronics and household appliances where performance requirements are relatively modest and cost sensitivity is paramount.

Ceramic circuit boards, however, leverage their superior performance to serve high-end sectors demanding exceptional thermal management, current-carrying capacity, insulation, and thermal stability. These include high-power power electronics modules, aerospace, and military electronics. For instance, in aerospace applications, electronic equipment must operate reliably under extreme temperature conditions. Ceramic circuit boards meet this requirement through their high reliability and excellent thermal stability. In military electronics, where equipment demands exceptional insulation and voltage resistance, ceramic circuit boards’ superior properties ensure safe and reliable operation.

Advantages and Disadvantages

Ceramic Circuit Boards

Advantages: High current-carrying capacity, meeting the power demands of high-wattage electronic devices; excellent heat dissipation, low thermal expansion coefficient, and dimensional stability preventing warping or deformation; superior insulation and high voltage resistance, safeguarding equipment and personnel; Strong bonding capability using bonding techniques prevents copper foil detachment; high reliability with stable performance in high-temperature and high-humidity environments.

Disadvantages: Fragility is a primary drawback, limiting its use to small-area circuit boards; relatively high cost, currently primarily applied in high-end products, making widespread adoption in low-end products challenging.

Conventional Circuit Boards

Advantages: Lower cost with mature production processes, meeting general electronic product requirements; wide applicability across consumer electronics and household appliances.

Disadvantages: Limited heat dissipation, prone to overheating in high-power applications; relatively weak current-carrying capacity, struggling to meet high-power electronic device demands; insulation and voltage resistance may fall short in high-end applications; thermal expansion coefficient mismatch, leading to warping and deformation.

Ceramic circuit boards and conventional circuit boards each possess distinct advantages and suitable applications. As electronic technology advances, demands on circuit board performance continue to rise. In the future, ceramic circuit boards are anticipated to gain broader adoption in more high-end sectors, while conventional circuit boards will persist in playing a vital role in traditional domains such as consumer electronics. Concurrently, with ongoing improvements in manufacturing processes and gradual cost reductions, ceramic circuit boards are also expected to become more widespread across diverse fields, propelling the electronics industry towards higher performance and greater reliability.