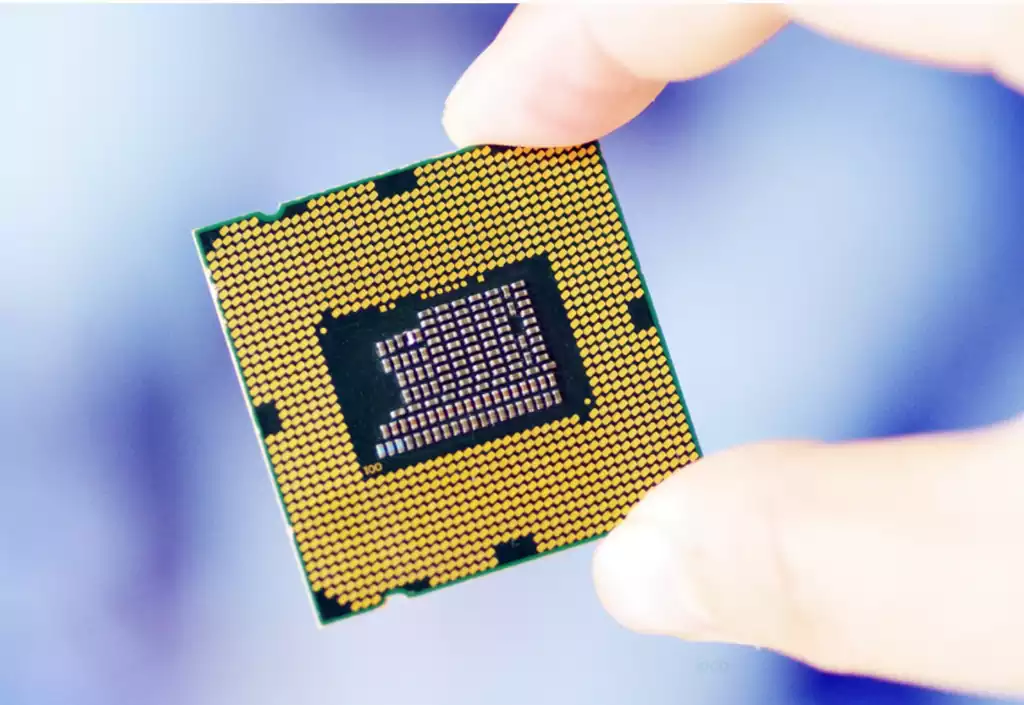

A chip pcb, also known as an integrated circuit, is an electronic component that integrates multiple electronic components on a small-sized substrate. Chips are typically made from one or more types of semiconductor materials, such as silicon and gallium arsenide. Compared to circuit boards, chips are smaller in size but more powerful, enabling higher performance and density.

The main function of a chip is to realize specific electronic functions, such as data processing, control, and communication. Several electronic components are integrated on the chip, such as CPU, GPU, memory, controller, etc., which can realize complex circuit functions in a very small space. Compared with circuit boards, chips are more specialized and powerful and can realize complex electronic functions at higher speeds and densities.

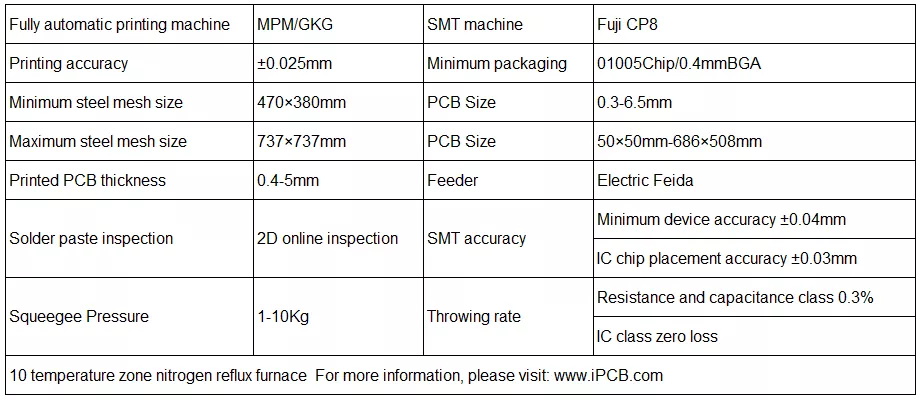

The manufacturing process for chips is very complex and consists of several key steps. First, a material preparation stage, typically using silicon as the substrate material, is performed by purifying and processing the silicon wafer to obtain high purity. Next, crystal growth is performed to form the basic framework of the chip by growing the desired crystal structure on the silicon wafer.

During the manufacturing process, the chip undergoes multiple processing and etching to form the desired circuits and components. One of the important process steps is doping, whereby the conductivity of a semiconductor material is altered by doping it with specific impurity elements. In addition, chip fabrication requires steps such as wiring, packaging, and testing to ensure chip performance and reliability.

The precision and complexity of the manufacturing process determine the performance and quality of the chip. As technology advances, chip manufacturing processes continue to evolve toward smaller size, higher integration, and lower cost.

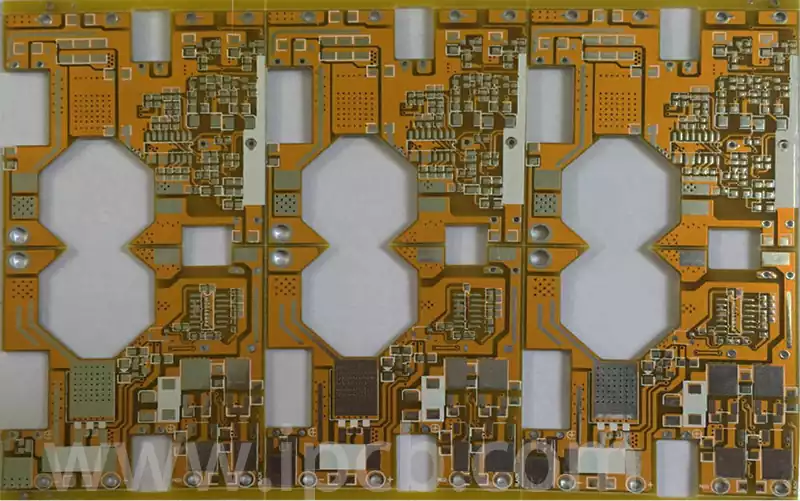

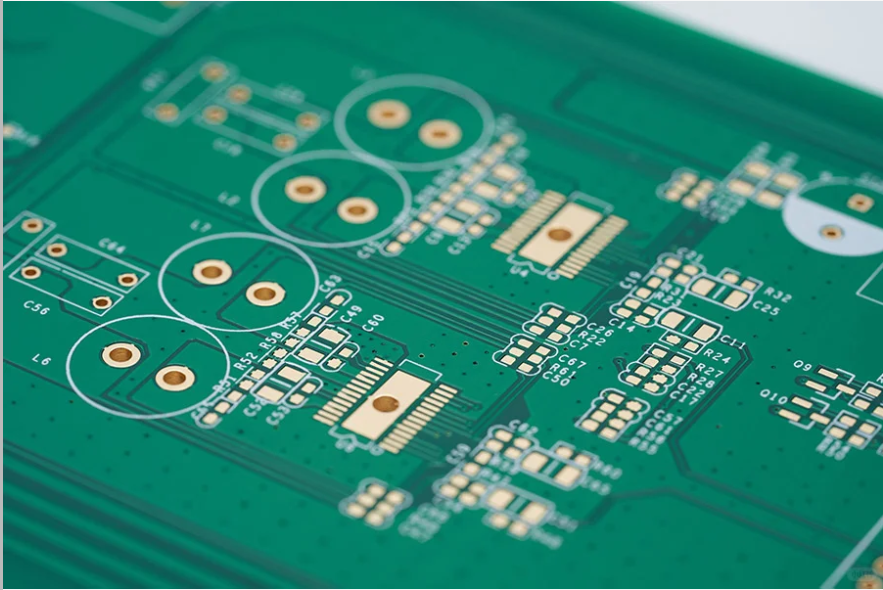

Chip pcb, as a crucial electronic component, has functions and application scenarios far beyond our imagination. They not only carry the transmission and distribution of current but also responsible for coordinating the communication and collaboration between various electronic components. In short, they are the “traffic commanders” in electronic devices, ensuring that data and information can flow unimpeded.

In smartphones, chip boards are responsible for running applications, storing and transferring data, and communicating with other devices. They ensure that we can make phone calls, send text messages, browse the web, and take photos and videos smoothly. Without them, smartphones would lose their intelligence and become like ordinary telephones.

In medical devices, chip boards play a crucial role. They are responsible for monitoring the patient’s vital signs, controlling the operation of medical devices and processing large amounts of medical data. For example, electrocardiographs, blood glucose monitors and CT scanners are all supported by chip boards.

In addition, in the field of aerospace, chip pcbs also play a pivotal role. They are not only responsible for controlling the navigation and stabilization of the vehicle, but also for processing a large amount of sensor data and communicating with other systems. Without them, the aircraft would not be able to take off and land safely.

As an important part of modern technology, chip pcb is not as conspicuous as smartphones or computers, but they are the “masterminds” that support the operation of the entire technological world. In the future, with the continuous development of science and technology, chip circuit boards will continue to play an indispensable role in promoting human society towards a smarter, more efficient new era.