The pcb board making machine is one of the key equipment in the production process of PCB circuit board. It mainly includes cutting machine, punching machine, milling machine and so on. Cutting machine is used to cut the large-size PCB board into the required size, punching machine is used to punch holes in the PCB board, and milling machine is used to remove the excess material from the PCB board. The accuracy and efficiency of these machines have a significant impact on the quality and productivity of PCB boards.

The main functions of PCB board making machine includes:

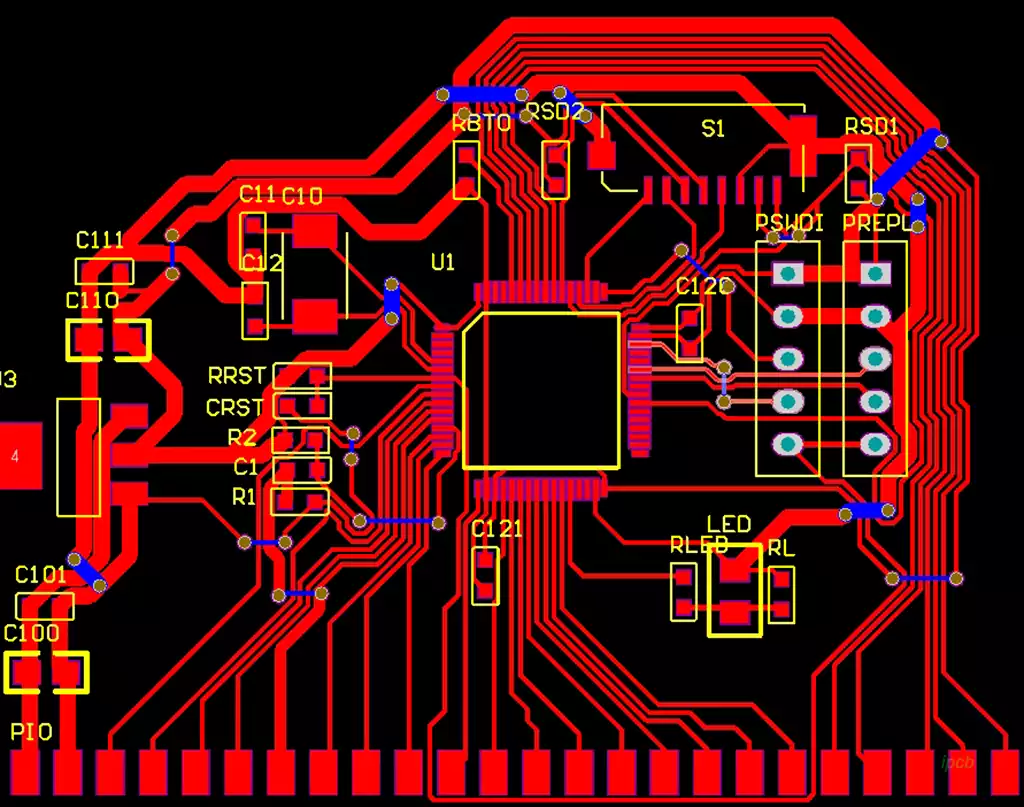

Line graphic processing: using photolithography to transfer the circuit design pattern to the substrate to realize the accurate division of the circuit.

Drilling: To open the necessary connection holes on the circuit board through high-precision drilling technology.

Coating Soldermask: To protect the copper layer of the PCB, soldermask material is coated to prevent oxidation and solder shorting.

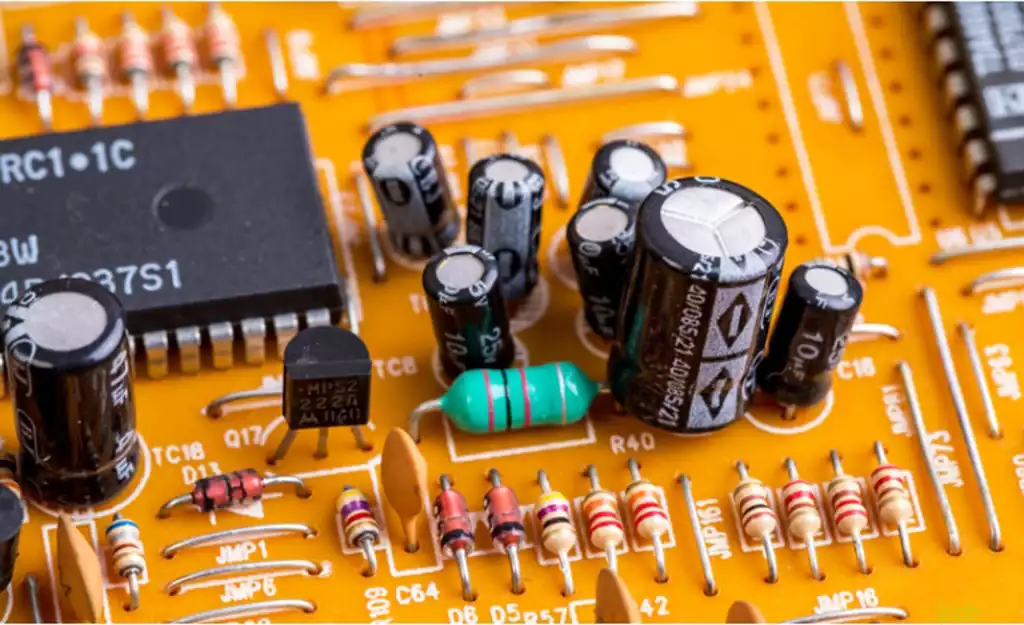

Copper Depositing and Plating: Depositing copper layers in specific areas to enhance the conductivity and connectivity of the circuit.

Types of PCB Fabrication Machines

PCB board making machine can be categorized into several main types based on different fabrication needs:

Photolithography Machine:

Mainly used to transfer circuit patterns to PCBs through photolithography.

Highly accurate and suitable for complex circuit board fabrication.

Drilling machine:

Dedicated to drilling holes accurately on the PCB to ensure the exact position and diameter of the connection holes.

High efficiency and precision are its main features.

Coating Equipment:

Responsible for coating solder resist materials to ensure uniform coating.

The choice of coating technology directly affects the protection effect of PCB.

Plating Machine:

Used to deposit metallic copper on specific areas to enhance circuit reliability.

Suitable for mass production.

PCB board making machine is vital in several industries. With the rapid development of electronic technology, the diversity and high efficiency of PCB board making machine make it become the core equipment of modern manufacturing industry, promoting the innovation and development of electronic products.

1.Application in medical equipment field

In the medical equipment industry, PCB board making machine is widely used in the manufacturing of various high-precision medical equipment, such as ECG machines, EEG machines, MRI machines and so on. The reliability and precision of these devices depend on high quality PCB boards, and the fabrication machine ensures efficient automatic assembly of line design and components.

- Applications in the automotive industry

The automotive industry has an increasing demand for electronic components, and PCB board fabrication machines play an important role in automotive electronics. They support the design of complex circuits, such as in-car navigation, infotainment systems and power control, to ensure that these systems operate normally in high temperature and vibration environments. - Industrial equipment applications

PCB board maker in industrial equipment has an important impact, especially in the need for high power output equipment, such as large servo motor drives and arc welding machines. These devices have strict requirements on the current carrying capacity of the PCB, the production machine is able to process a thick copper layer of PCB to adapt to the high current demand. - Consumer electronics applications

Consumer electronics, such as smart phones, tablets and computers, rely on miniaturized and high-performance PCBs, and the efficient production process of PCB fabrication machines makes it possible to rapidly iterate on these devices to meet changing market demands. - Aerospace applications

In the aerospace industry, PCB fabricators are used to create lightweight, high temperature and vibration resistant flexible PCBs, which are critical to the overall performance of spacecraft. These flexible PCBs can be installed in limited spaces, reducing overall weight and improving structural stability. - Application of Robotics

With the development of automation and robotics, PCBs have become a core component of robotic systems. the application of PCB fabrication machines in this area has enabled robots to operate more efficiently and has driven technological innovation and progress in the industry.

Advanced technologies in PCB board making machine plays a key role in improving the efficiency and accuracy of circuit board production. As the demand for electronic products continues to grow, these technologies continue to evolve to meet the needs of high performance, low cost and complex designs.

- Automation and Intelligent Technology

Modern PCB board making machine is increasingly using automation and intelligent technologies to make the production process more efficient and precise. These machines are able to automate all aspects of design, manufacturing and testing, reducing the need for human intervention while improving overall production efficiency and product consistency. - High-precision processing technology

High-precision CNC machine tools and laser cutting technology is one of the key factors to promote PCB processing accuracy. These technologies enable precise cutting and processing of line patterns, ensuring high-density layout of circuits and good transmission of signals. Especially in multilayer PCB design, high-precision processing helps to improve signal integrity and reduce interference. - Application of new materials

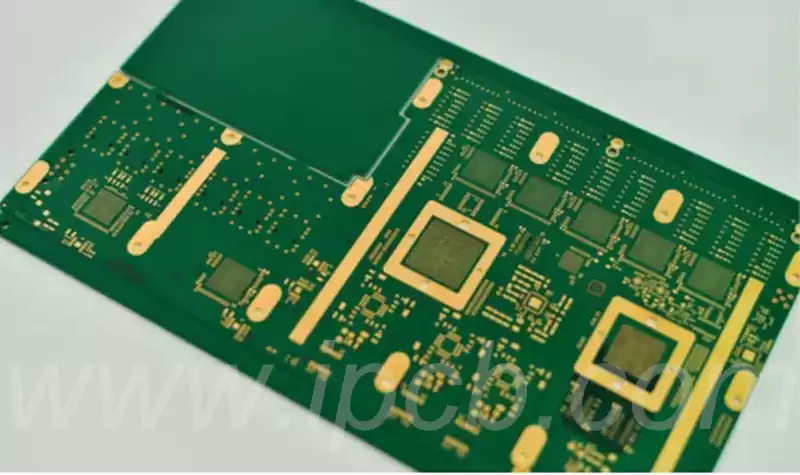

The application of new materials in the production of advanced PCB boards also significantly improves product performance. For example, the use of low dielectric constant and low loss materials can improve the signal transmission speed and stability of the PCB to meet the needs of high-speed communication and data transmission. The use of these new materials not only improves the overall performance of the PCB, but also extends its service life. - High Density Interconnect (HDI) technology

HDI technology is an important means of realizing high-density integration and complex circuit layout. This technology can realize more functions in limited space through fine line design and high-level integration, meeting the demand for compact design in modern electronic products.HDI technology enhances the performance of PCBs, making them widely used in mobile devices and automotive electronics. - Environmentally friendly and sustainable technologies

Environmental protection and sustainability are also becoming important developments in PCB manufacturing. Many companies are adopting lead-free materials and biodegradable production processes to minimize waste and environmental impact during production. This shift not only meets the market’s requirements for environmental protection, but also enhances the social image and competitiveness of companies.

As a key equipment in modern electronic manufacturing, PCB board making machine is crucial to the development of various industries with its precise and efficient production process. With the continuous progress of technology and changes in market demand, PCB board making machines will continue to promote the innovation of electronic products and enhance production efficiency and quality. In the future, these machines will be more intelligent and environmentally friendly, meeting the demands of more complex and high-performance designs.