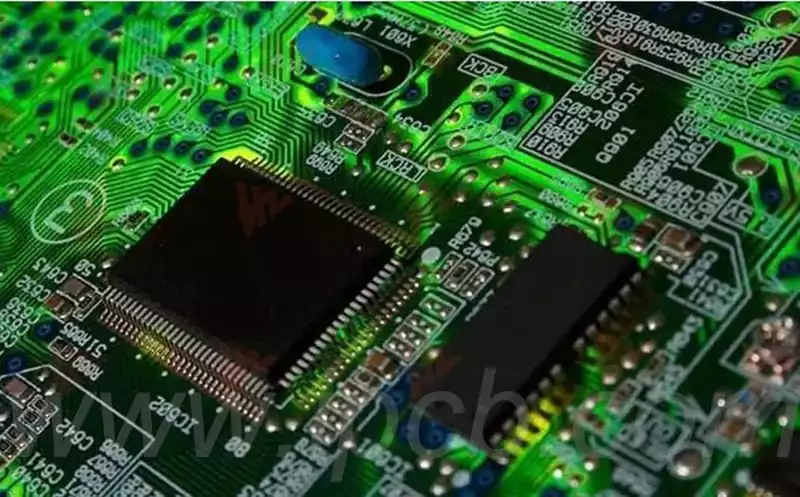

High speed pcb sheet has the characteristics of low dielectric constant and low dielectric loss, which helps to significantly reduce the energy loss and distortion during the signal transmission process, thus improving the transmission speed and stability of the signal. In the high-frequency and high-speed digital signal transmission scenarios, the appropriate choice of high-speed sheet can significantly reduce the signal transmission delay, effectively inhibit crosstalk and reflection phenomena, to ensure the integrity of the signal transmission and its reliability.

Why pcb manufacturing should use high speed pcb sheet?

Reduce the energy loss in signal transmission: High speed pcb sheet with low dielectric constant and dielectric loss characteristics, can reduce the energy loss in signal transmission, to ensure the integrity of the signal error-free transmission.

Enhance the efficiency of signal transmission: High speed pcb sheet helps to shorten the delay time of signal transmission, thereby increasing the transmission rate of the signal, which is perfectly suited to the stringent requirements of high-speed digital signal transmission.

Reduce signal interference and reflection: High speed pcb has a significant effect on reducing crosstalk and reflection between signals, effectively preventing signal interference and distortion and ensuring the stability and reliability of circuit operation.

High-frequency and high-speed HDI (High-Density Interconnect) multilayer board cost by a variety of factors, including the following key points:

Raw material costs: HDI multilayer board selection of special substrates, such as high-frequency, low-loss materials, etc., the price is far more than ordinary PCB materials. At the same time, copper foil specifications and optical fibre materials, etc. are also important factors in determining the cost.

Production Process Complexity: The production of HDI multilayer boards involves complex processes, such as micro-blind technology, high-density line layout and laser drilling, etc. These processes not only require high-precision production equipment, but also enhance the technical threshold, which in turn pushes up the production cost.

Number of layers and structural design: The number of layers and their structural design of multilayer boards directly affect the difficulty of production and the amount of material used. More layers means more complex stacking and processing, and the cost increases accordingly.

Production batch size: The impact of production scale on cost should not be ignored. Large-scale production can reduce unit costs by sharing fixed costs, while small-lot production leads to higher costs because of the inability to enjoy economies of scale.

Inspection and quality control: In view of high-frequency and high-speed applications of PCB quality requirements, it is necessary to increase the testing and inspection links, which will bring additional testing equipment and manpower costs.

Market demand and supply and competitive situation: market demand fluctuations and competitive situation will also affect the cost. When demand exceeds supply, prices may rise; conversely, they may fall.

The application of high speed pcb in PCB manufacturing, especially in high-frequency and high-speed digital signal transmission scenarios, has irreplaceable advantages, however, the application of high-speed boards is also accompanied by cost considerations. In the PCB manufacturing process, it is necessary to take into account the performance requirements and cost-effective, reasonable selection of high-speed sheet to achieve the best performance and cost balance.