PCBA control board is assembled printed circuit boards (PCBs) on which various electronic components have been soldered to realize specific functions. It usually consists of a substrate, electronic components, soldering points, etc., and is the core part of all kinds of electronic products. One of the electronic components can be resistors, capacitors, integrated circuits, etc., which are connected to the PCB through welding and work together to realize the function of the circuit.

The main role of PCBA control board is to realize the connection and control of the circuit. It forms a complete circuit system by soldering various electronic components onto a printed circuit board (PCB). These electronic components are connected together through the soldering points, together to realize the function of the circuit, to ensure that the equipment can operate normally.

In the field of consumer electronics products, such as cell phones, computers, tablet PCs, TVs, etc., pcba control board is the core components to realize the function and control of the equipment. They carry a variety of functional modules of the device, such as CPU, memory, camera, screen, etc., and by controlling the flow of current, to achieve the various functions of the device.

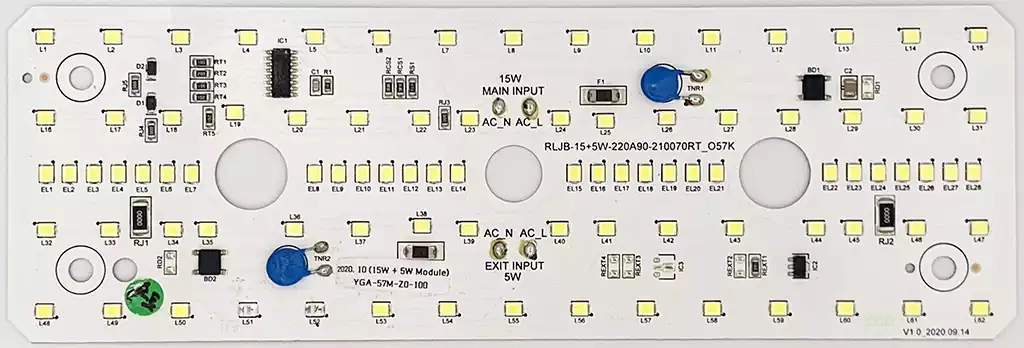

Smart home products such as smart sockets, smart bulbs, smart door locks, etc., it is responsible for receiving and processing user commands, controlling the switch, brightness, color temperature, etc. of the home equipment, providing users with an intelligent life experience.

For industrial equipment such as automated production lines, robots, sensors, etc., it is responsible for receiving and processing various sensor signals, controlling the operation and stopping of the equipment, ensuring the stable operation of the production line and product quality.

Production Process

Customer demand analysis: Define the customer’s demand, including the specification, function and quantity of the pcb board. This is the first step in the production process to ensure that the subsequent production process meets the customer’s requirements.

Design Documentation Preparation: Prepare the appropriate circuit diagrams (schematics), PCB design documents (e.g. Gerber documents) and BOM (Bill of Materials) according to the customer’s requirements. These documents will serve as an important basis for the production process.

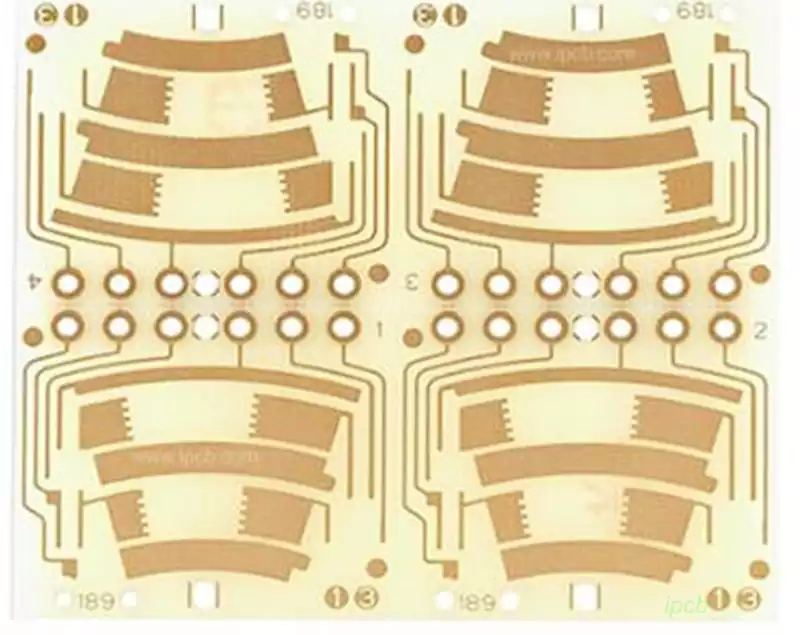

PCB Manufacturing: Entering the PCB manufacturing stage, which includes steps such as PCB board preparation, graphic transfer, etching, soldermask production, and silkscreen marking. These steps ensure that the quality and performance of the PCB meets the design requirements.

Component Procurement and Inspection: Procure the required electronic components, such as resistors, capacitors, integrated circuits, etc., according to the BOM list. And the appearance of the purchased components, electrical performance and other aspects of the inspection to ensure that the quality of components qualified.

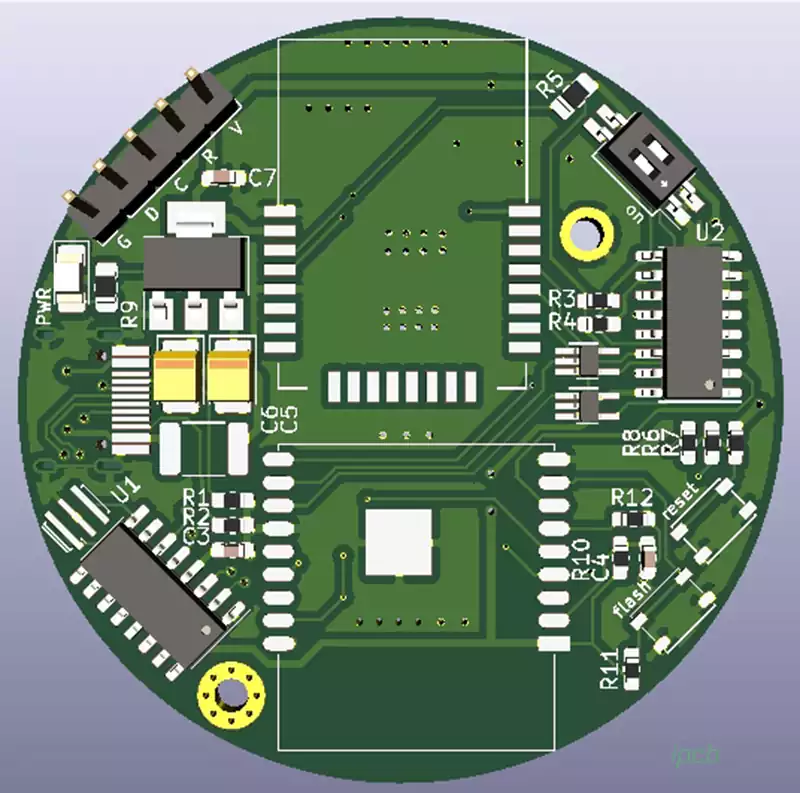

PCBA assembly: enter the PCBA assembly stage, including SMT mounting, DIP insertion, welding, cleaning and other steps. SMT mounting is the process of mounting small components onto the PCB, and DIP insertion is the components that can not be mounted by SMT mounting manual or machine insertion. The soldering step connects the components firmly to the PCB, and the cleaning step removes flux and oxide residues generated during the soldering process.

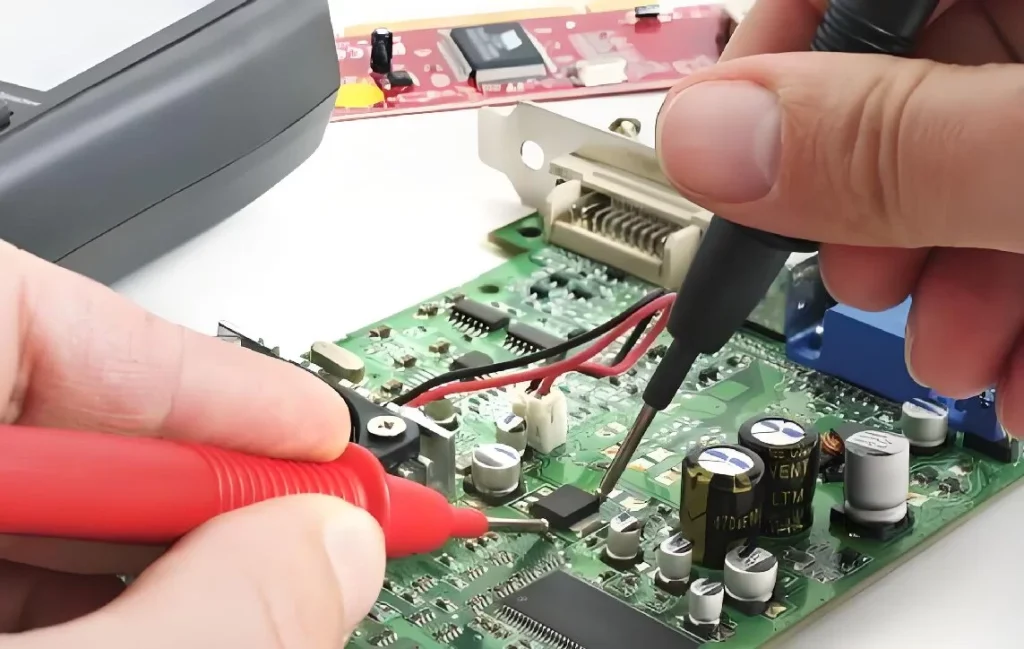

Testing and Inspection: After the assembly is completed, ICT testing, functional testing, appearance inspection and reliability testing are carried out. ICT testing is carried out through an in-line tester to test the electrical performance of the PCBA, functional testing simulates the actual working environment to verify the functionality of the PCBA, appearance inspection is carried out to check the appearance quality of the PCBA, and reliability testing is carried out to assess the performance of the PCBA in harsh environments.

Packaging and shipping: Finally, the qualified PCBA will be packaged according to the customer’s requirements to prevent damage during transportation and storage. And according to the customer’s requirements of the time and place of shipment, to provide the appropriate shipping documents and information.

PCBA control board is an indispensable part of electronic devices, they provide powerful functional support for various electronic devices by realizing the connection and control of circuits