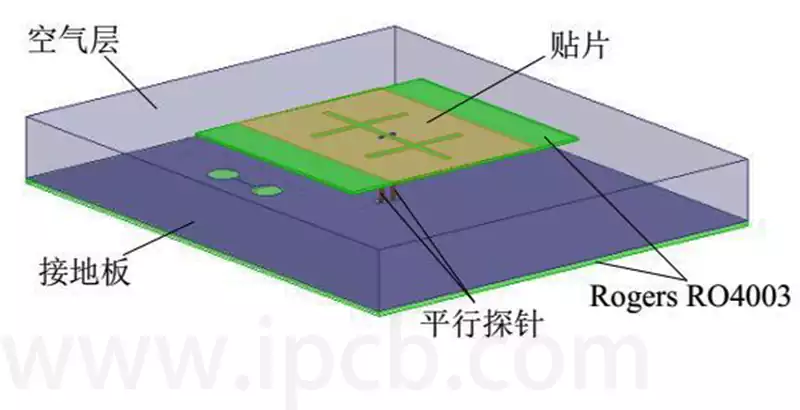

An ultrasonic circuit board is an electronic component that utilizes ultrasonic waves for signal transmission. It utilizes the piezoelectric effect of piezoelectric ceramics and other materials to convert electrical signals into ultrasonic signals for transmission. Ultrasonic circuit board is mainly composed of piezoelectric ceramics, metal electrodes, insulation layer and circuit board. When the electrical signal is added to the piezoelectric ceramics, the piezoelectric ceramics will vibrate, thus generating ultrasonic waves, ultrasonic waves propagate in the medium and are reflected back in the metal electrode, and then converted into electrical signals through the piezoelectric ceramics, thus realizing the transmission of signals.

Ultrasonic circuit board features:

- High-frequency transmission: ultrasonic frequency is very high, can be used for high-speed signal transmission, to achieve high-speed data transmission and high-capacity information transfer.

- low loss: ultrasonic propagation in the medium when the attenuation is small, can be used for long-distance transmission, and transmission loss is small, is conducive to signal fidelity and stability.

- High speed: the response speed is very fast, the signal transmission can be completed within milliseconds, suitable for high-speed signal processing and transmission.

- High reliability: the use of metal electrodes and piezoelectric ceramics and other materials, with high reliability and stability, can be adapted to a variety of harsh environments.

- Miniaturization: small size, can be used in miniaturized equipment, easy to integrate and assemble.

- At present, there is still much room for improvement in the energy conversion efficiency of ultrasonic drive circuit boards. In the future, with the continuous development of materials science and manufacturing technology, there will be more efficient and stable ultrasonic transducer and subsequent circuitry, thus improving the energy conversion efficiency of ultrasonic drive circuit board.

Principle of operation

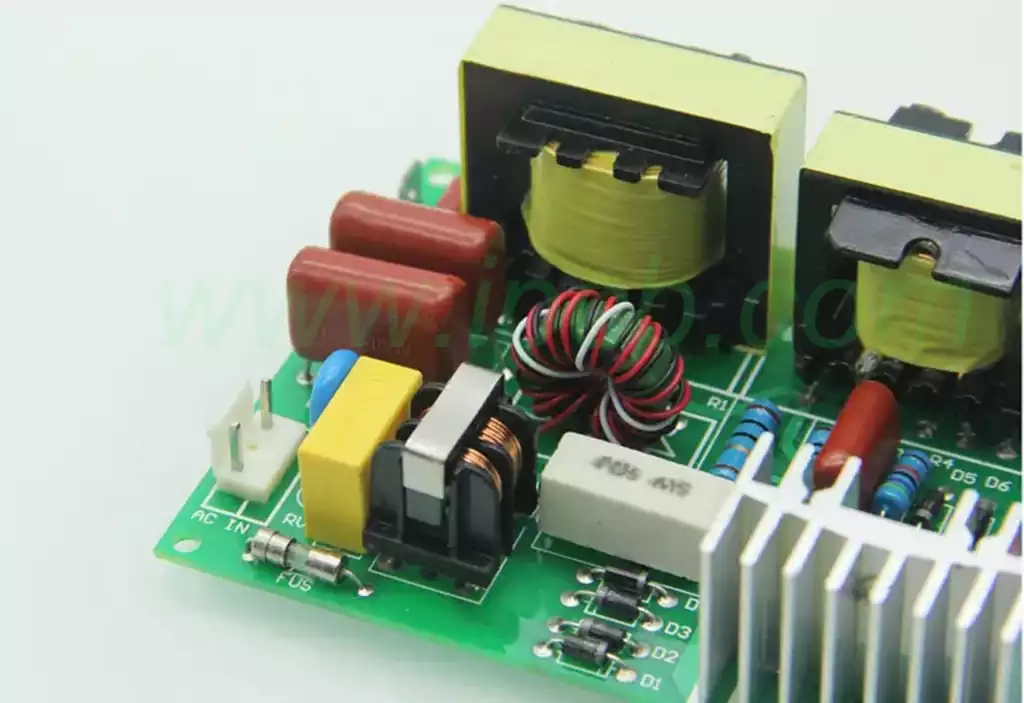

Mainly rely on the mechanical vibration and cavitation effect generated when ultrasonic waves propagate in the liquid. This vibration and effect can effectively remove dirt and impurities from the surface of objects. The following is a detailed explanation of the working principle of this circuit board: When ultrasonic waves propagate in the liquid, it will produce a series of tiny bubbles. These bubbles will rapidly expand and contract under the action of ultrasonic waves, forming a strong impact and shear force, thus effectively removing dirt and impurities on the surface of the object. Ultrasonic circuit boards usually use piezoelectric ceramic elements as the ultrasonic emission material. These components can convert electrical energy into ultrasonic signals, or ultrasonic signals into electrical signals, so as to realize the conversion of energy and signal processing. In some advanced ultrasonic circuit boards, such as low-power ultrasonic circuit boards, a digital signal processor (DSP) is used to control the transmission and reception of ultrasound. This technology increases flexibility and scalability while reducing cost and size.

The main application scenarios of ultrasonic circuit boards lie in the following areas:

- Medical field: In the medical field, it is widely used in ultrasound imaging, ultrasound lithotripsy, ultrasound therapy, etc.. It can convert electrical energy into mechanical energy, so as to detect, locate and destroy diseased tissues, which provides a new means for medical diagnosis and treatment.

- Industrial field: In the industrial field, it is used in ultrasonic cleaning, ultrasonic welding, ultrasonic processing and so on. It can generate high-frequency vibration to transfer energy to the surface of the workpiece, so as to efficiently clean, weld and process the workpiece, improving the efficiency and quality of industrial production.

- Scientific research field: In the field of scientific research, it is used in physical research, chemical research, biological research and so on. It can produce high-precision ultrasonic waves to manipulate and study microscopic particles, so as to make an in-depth investigation of the internal structure and properties of substances.

The design and fabrication process of ultrasonic circuit board includes the following steps:

- Selection of suitable piezoelectric ceramic materials: piezoelectric ceramics are the core components of such circuit boards, and suitable materials need to be selected according to the application scenario and actual needs. Different piezoelectric ceramic materials have different performance indexes, such as frequency range, mechanical quality factor, resistivity, etc., which need to be selected according to the actual situation.

- Design of suitable circuit: It is necessary to design suitable circuits to realize the conversion of electrical energy and mechanical energy. PCB design needs to consider the voltage, current, frequency and other parameters, as well as the signal input and output methods and the stability and reliability of the circuit.

- Production of metal substrates: metal substrate is an important part, it needs to have a certain degree of rigidity and stability, and need to have good thermal conductivity and electrical conductivity. Commonly used metal substrate materials include aluminum, copper and so on.

- Assembly and debugging: piezoelectric ceramics, circuits and metal substrates and other components are assembled together, and debugging to ensure that they can work properly and achieve the expected performance indicators. The debugging process needs to adjust and optimize the circuit to achieve the best electrical and mechanical energy conversion effect.

Ultrasonic circuit board, with its high frequency, low loss, high speed and high reliability characteristics, is leading the innovation of signal transmission technology. Looking to the future, with the continuous progress of technology, it will show unlimited potential in more fields, contributing more power for the progress of science and technology.