LTCC (Low-Temperature Co-fired Ceramic) technology, a multilayer circuit technique originating in the 1980s, holds a pivotal position in high-density and high-frequency electronics. This process commences with the use of green ceramic powder, meticulously formed into green ceramic tape via a casting process. Subsequently, each layer undergoes sequential punching operations, precise filling of through-hole metal pastes, and meticulous printing of circuit patterns and resistor designs. Finally, the individual ceramic layers are precisely aligned and stacked, subjected to pressure bonding, then sintered at temperatures between 850°C and 900°C. This process fuses the layers into a cohesive whole, ultimately forming a multilayer ceramic circuit with exceptional performance.

LTCC technology demonstrates formidable application potential in high-density packaging due to its significant technical advantages, including low dielectric constant and arbitrary multi-layer routing, establishing itself as an effective means for achieving high-density packaging. However, the manufacturing process for LTCC multilayer circuit substrates is exceptionally lengthy and highly complex. Critical parameters such as substrate shrinkage rate, warpage, and interlayer alignment accuracy exert a decisive influence on product performance. Presently, these factors represent critical control challenges in LTCC substrate manufacturing that require urgent resolution. Researchers must conduct sustained, in-depth investigations to continually refine and optimise LTCC production processes.

In-depth Analysis of Influencing Factors

Detailed Investigation into Causes of Shrinkage Rate Deviation

The shrinkage rate of LTCC exhibits a direct correlation with material density. Specifically, higher material density correlates with lower shrinkage rates, while lower material density corresponds to higher shrinkage rates. At the process parameter level, material density corresponds directly to lamination pressure. Therefore, by precisely controlling lamination pressure, the shrinkage rate of LTCC products can be effectively modified to meet design specifications with accuracy. However, it is crucial to note that the manufacturer’s provided ‘isostatic pressure – shrinkage rate’ curve is derived from measurements taken after sintering the white ceramic substrate. In actual LTCC substrate manufacturing, the presence of metal vias and printed conductive traces on the substrate introduces significant differences in shrinkage rates between these metallic components and the white ceramic substrate. Consequently, under identical lamination pressure conditions, the shrinkage rate of LTCC products will inevitably deviate to some extent from that of white porcelain. This necessitates researchers conducting further in-depth investigations into the underlying principles, extensively accumulating process data, and accordingly adjusting the lamination pressure to ensure the shrinkage rate meets design specifications.

Multidimensional Analysis of Substrate Warpage Causes

The sintering shrinkage rate and warpage of LTCC substrates constitute crucial indicators for evaluating LTCC substrate manufacturing quality. These properties are not only intrinsically linked to the sintering process but also closely related to substrate symmetry design, circuit layout, and paste selection.

Sintering Process Factors: The sintering process of LTCC substrates fundamentally involves an intricate interplay of exothermic and endothermic reactions. During the de-sizing stage (approximately room temperature to 500°C), organic compounds within the substrate decompose and volatilise, resulting in mass reduction. Subsequently, during the sintering stage (approximately 700°C to 850°C), crystallisation and recrystallisation reactions occur internally. As these reactions progress, the substrate gradually contracts. It is evident that the sintering duration at both low and high temperatures, alongside the heating rate, exhibits a close correlation with the substrate’s degree of shrinkage and warpage. To effectively control substrate shrinkage and warpage, meticulous optimisation of the sintering curve is required. This involves extensive experimentation to adjust critical process parameters such as the heating rate and duration during the de-gassing phase, the heating rate and duration during the sintering phase, and the air flow rate at each stage.

Substrate Structure and Metal Distribution Factors: The structural design of LTCC substrates is a key determinant of their sintering warpage. When LTCC substrates incorporate multiple cavity structures of varying specifications, achieving overall symmetrical balance becomes challenging. Concurrently, the presence of numerous vias and densely packed metallic conductors on the substrate often results in uneven distribution of these elements. Such structural asymmetry and non-uniform metal distribution readily cause excessive warpage during sintering. Consequently, the substrate design phase must prioritise structural symmetry and uniform metal distribution to mitigate warpage risks.

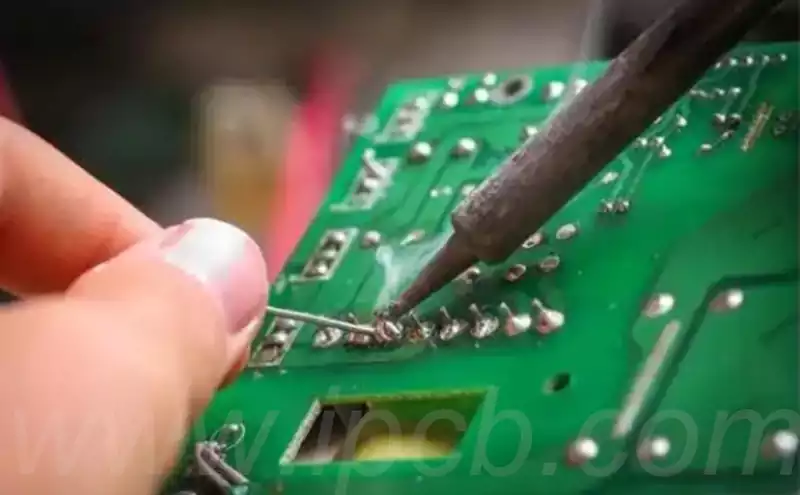

Factors in paste selection: The thermal expansion coefficients of different silver pastes, gold pastes, and green ceramic tapes exhibit varying degrees of compatibility. When employing different pastes across large printed areas, this discrepancy exerts a particularly pronounced effect on substrate warpage. Consequently, paste selection must prioritise thermal expansion coefficient compatibility with the green ceramic tape, favouring well-matched formulations to mitigate warpage issues arising from unsuitable paste choices.

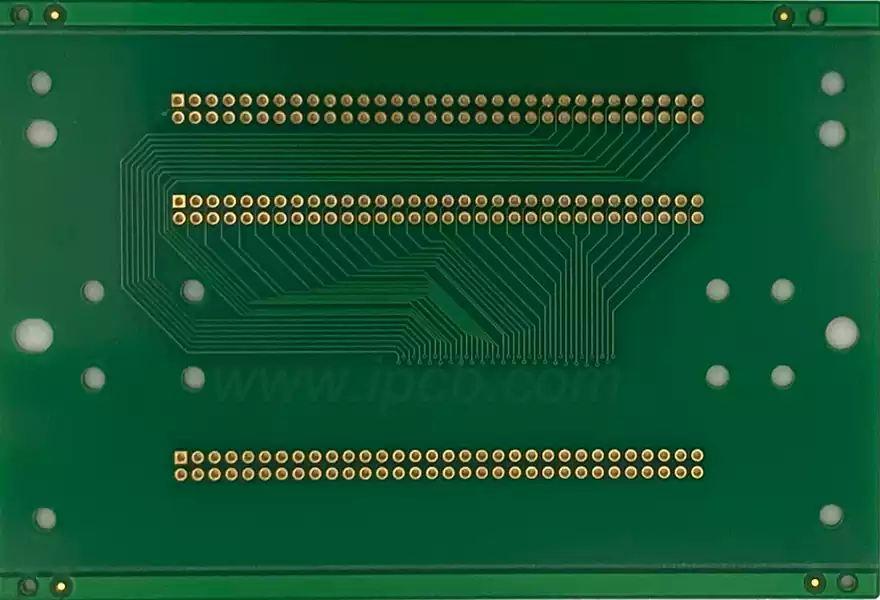

Comprehensive Analysis of Interlayer Misalignment Causes in Through-Holes

Interlayer misalignment in LTCC substrates presents a complex challenge, interrelated with numerous factors including drilling precision, the shrinkage characteristics of the green ceramic substrate itself, the condition of printed conductors across layers, and stacking alignment accuracy. This constitutes one of the most challenging aspects to control within the LTCC manufacturing process. To effectively control interlayer alignment deviation, comprehensive and meticulous monitoring of the entire process flow is required. Data analysis should identify primary influencing factors, followed by optimised control measures targeting these elements. For instance, enhancing the precision of drilling equipment, ensuring uniform shrinkage of green tiles during sintering, optimising printing conductor process parameters, and improving stacking alignment accuracy are all effective measures to reduce interlayer alignment deviation.

LTCC technology holds vast application prospects in high-density and high-frequency electronics, yet its manufacturing process confronts numerous challenges. Through in-depth analysis and optimised control of critical factors such as shrinkage rate deviation, substrate warpage, and via layer-to-layer alignment deviation, it is anticipated that the manufacturing process level of LTCC substrates will be continuously enhanced, propelling the widespread application of LTCC technology across more fields.