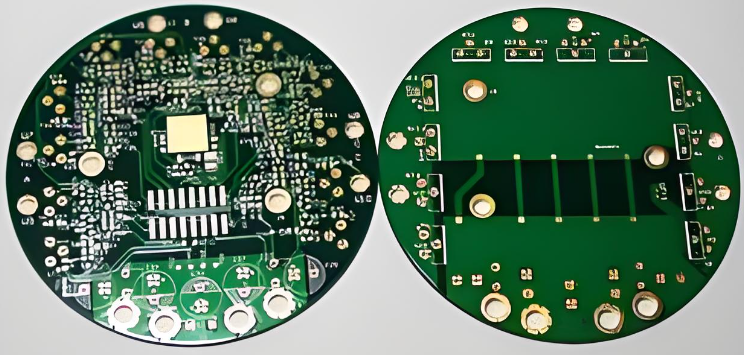

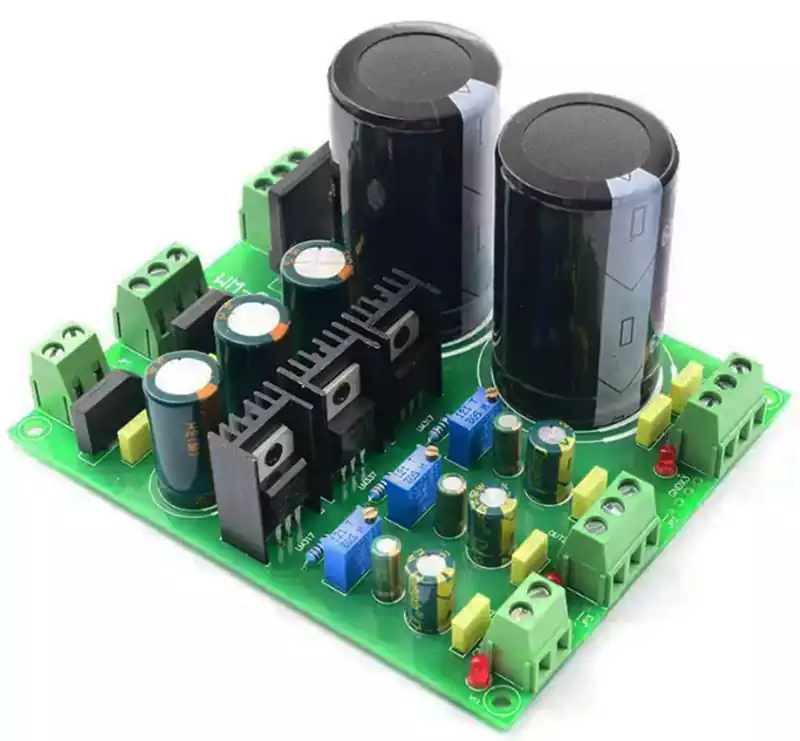

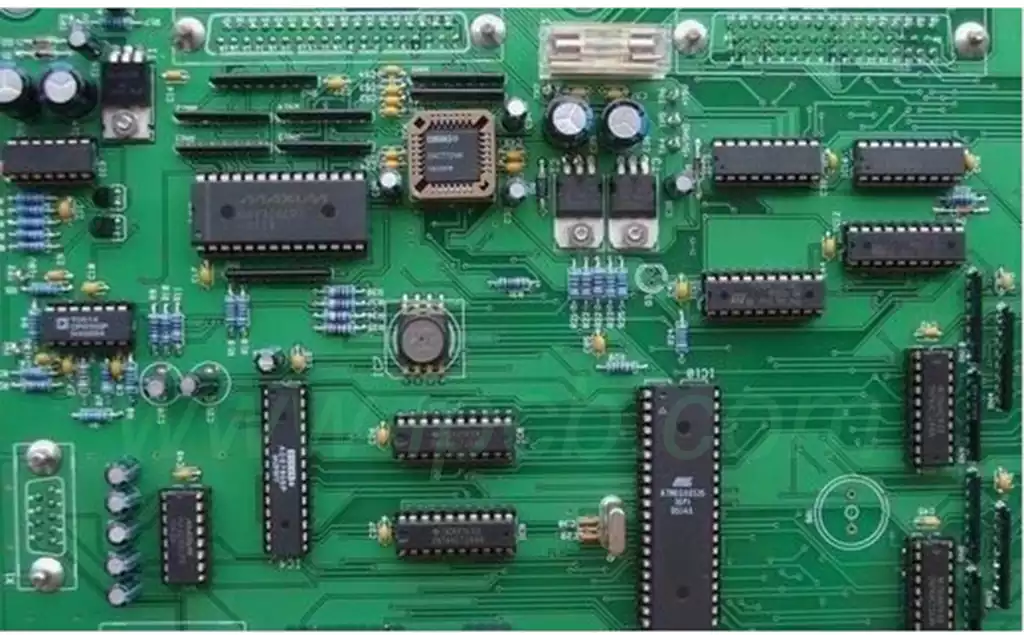

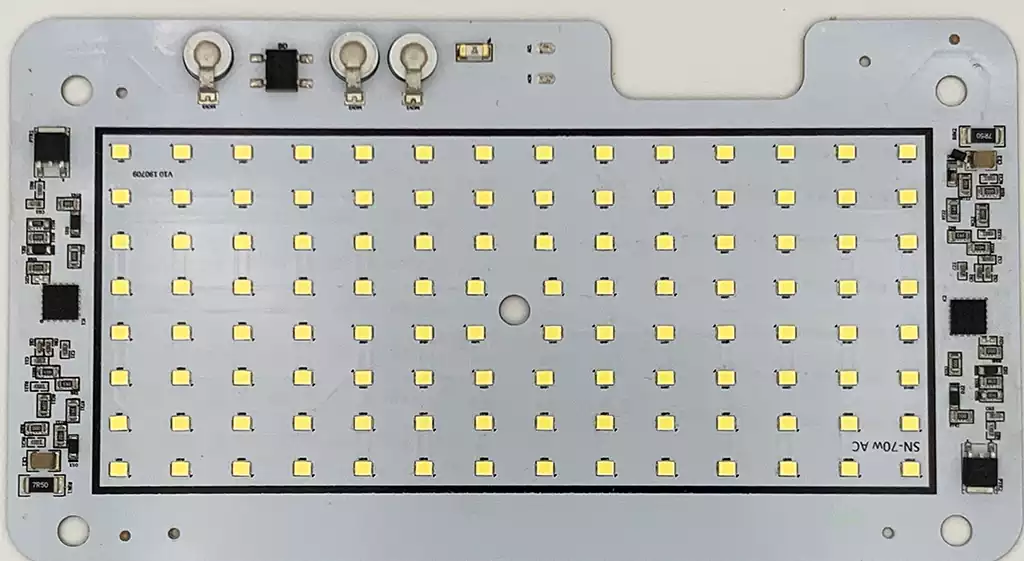

What is the pcba meaning in electronics?Its full name is Printed Circuit Board Assembly,refers to the electronic components, connectors, plug-ins, digital logic gates, micro-control units, etc. assembled to the circuit board, and then a variety of welding and insertion and other processes, so as to become a complete functional module of electronic products.

Difference between PCB and PCBA

Conceptually, PCB is an empty printed circuit board without any components, it only provides support for the fixing and electrical connection of electronic components.PCBA is a finished circuit board,the main function is to finish the Assembly and welding of components to enable normal operation.

The main advantages of the PCBA process are increased productivity and quality, and reduced costs. Compared with traditional manual soldering, it uses automated equipment and processes, which greatly reduces labor costs and error rates in the production process. In addition, the process can also ensure the quality and consistency of the products produced, reducing the rate of nonconforming products and improving product reliability and stability.

PCBA process is widely used in the electronics manufacturing industry. For example, it can be used to produce a variety of consumer electronics products, such as smart phones, tablet PCs, televisions and so on. In addition, it can also be used to produce a variety of industrial control equipment, automotive electronic equipment, medical equipment and so on.

PCBA manufacturing process mainly includes the following steps:

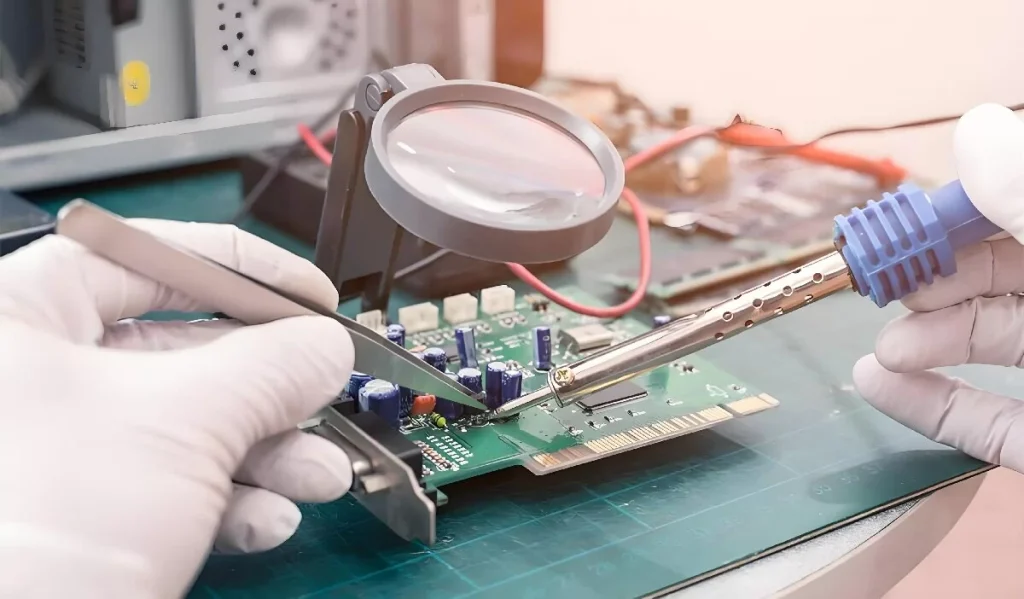

SMT SMD processing: this step includes solder paste mixing, solder paste printing, SPI (solder paste thickness tester) inspection, placement, reflow soldering.AOI (automatic optical inspection) inspection and rework.

DIP Insertion Processing. This step includes insertion, wave soldering, foot trimming, post-solder processing, board washing and quality control.

PCBA testing: This step includes functional testing, aging testing and vibration testing, etc., which requires different testing methods to be selected according to the different requirements of products and customers.

Protective Coating Processing: This step includes painting one side, curing, then painting the other side, room temperature curing, and spraying thickness. All coating work should be carried out at not less than 16 degrees Celsius and less than 75% relative humidity.

Finished Product Assembly: This step includes assembling the tested PCB boards for the enclosure, then testing them, and finally they are ready to be shipped.

The PCBA manufacturing process is a complex and delicate process that requires close cooperation and strict control of multiple roles such as designers, engineers, and workers.