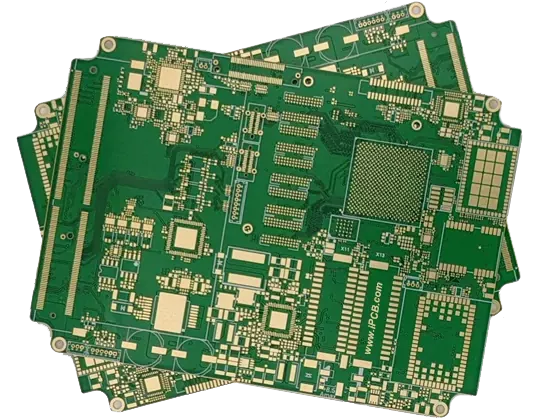

Printed Circuit Board = PCB, PCB is an important electronic component, the support body of electronic components, and the carrier of electrical connections.

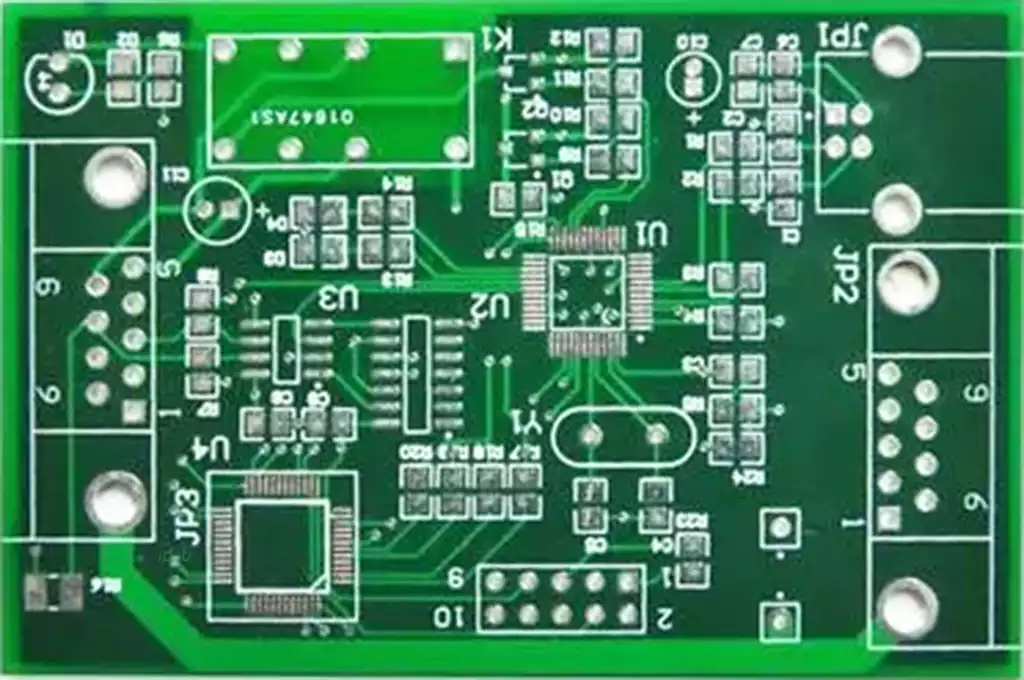

Circuit board realizes the connection between electronic components and signal transmission by printing lines on insulated substrates. There are various types of PCB boards according to different classification criteria.

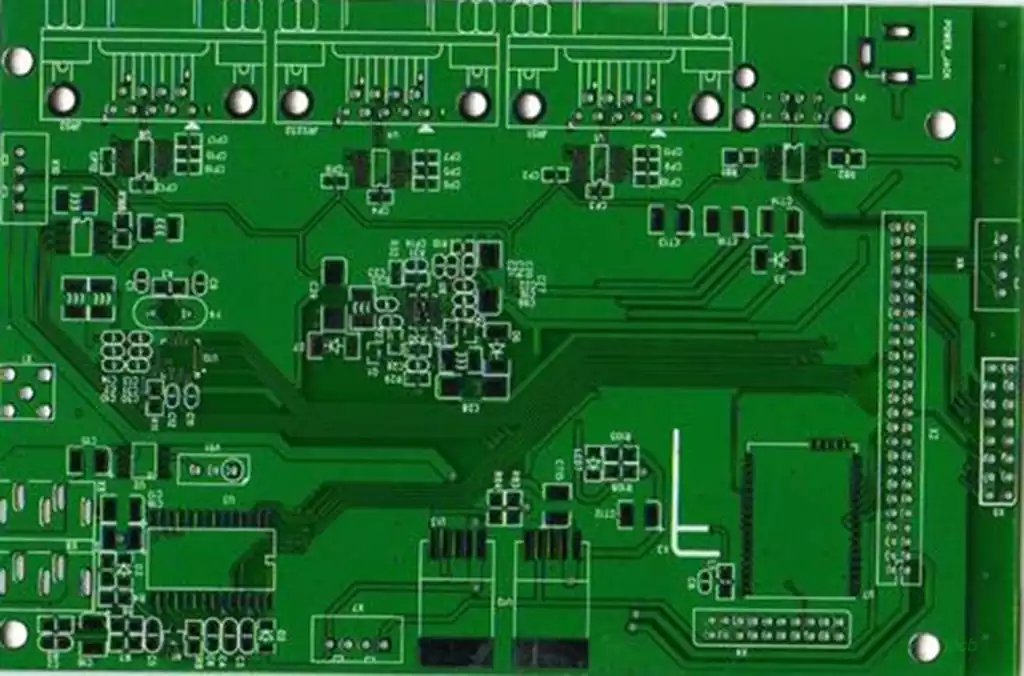

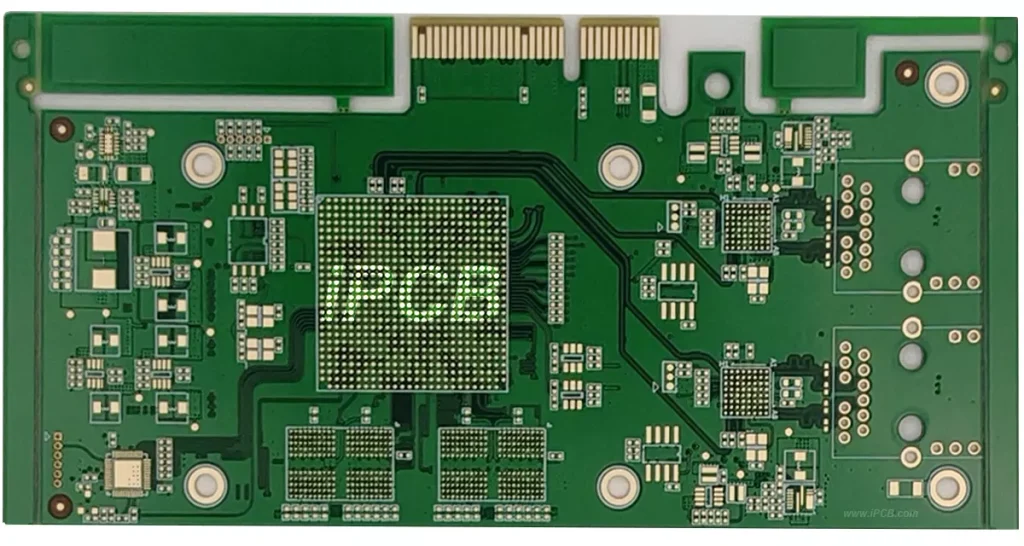

According to the number of Circuit Board layers, printed circuit boards can be categorized into single-sided Circuit Board, double-sided Circuit Board, and multilayer Circuit Board. Single-sided printed circuit boards have wires and components on one side only, while the other side is empty. double-sided printed circuit boards have wires on the front and back sides to connect components and multilayer printed circuit boards are composed of multiple layers of wires and insulation, allowing for more complex PCB circuit designs.

Depending on the layout of the wires and how they are connected, they can be categorized as rigid circuit boards or flexible circuit boards. Rigid circuit boards are made of rigid substrates with flat lines. flexible circuit boards are made of flexible materials that can be bent for easy installation.

According to the assembly method of electronic components, it can be divided into surface mount boards and through-hole insertion boards. Surface mount boards are suitable for surface mount components (e.g., chip resistors, capacitors, etc.), while through-hole cartridge boards are suitable for through-hole cartridge components (e.g., pin-type resistors, capacitors, etc.).

In addition, according to the use of different environments and performance requirements, they can also be categorized into ordinary Printed Circuit Board boards, high-density interconnect PCBs, high-frequency Printed Circuit Board, metal aluminum PCBs, thick copper foil PCBs, and so on. Different types of printed circuit boards have different characteristics and scope of application and need to be selected according to specific needs.

The production process of printed circuit boards mainly includes the following steps:

Line design: According to the circuit schematic diagram, use professional software for Printed Circuit Board line design. The design process needs to consider the signal transmission, component layout, wiring rules, and other factors.

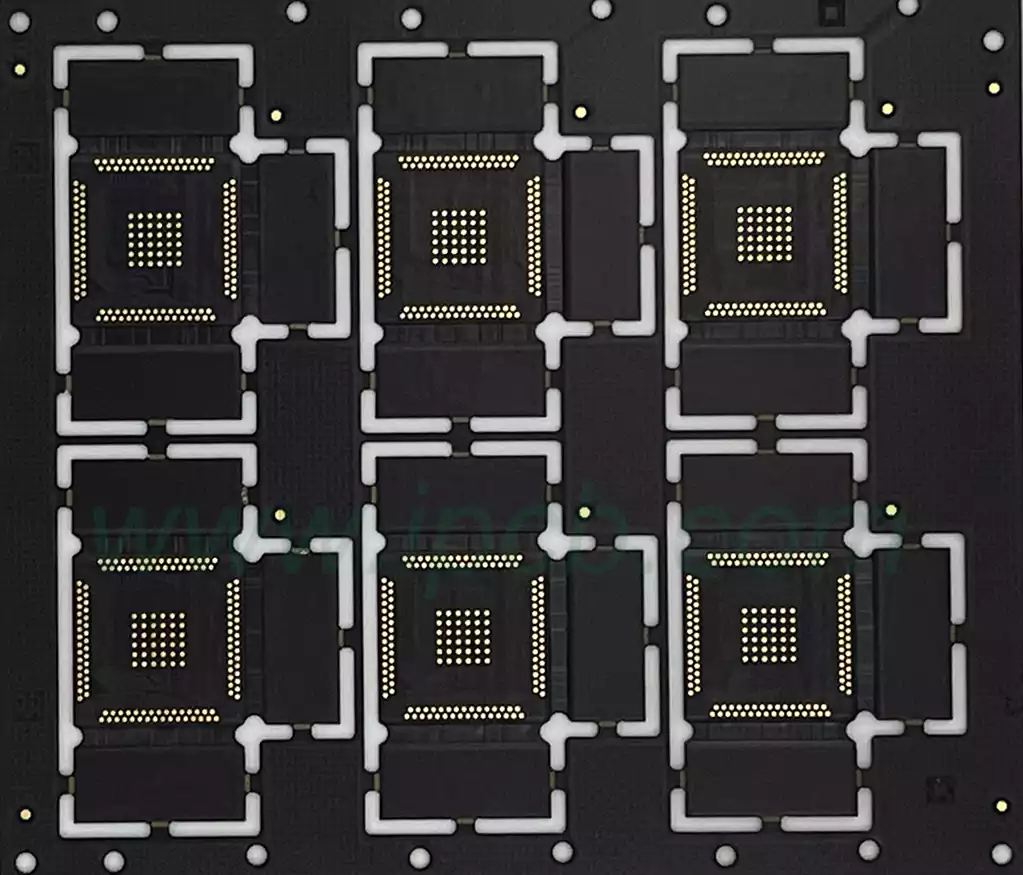

Copper-clad board production: insulating materials (such as FR4 or CEM-1) as a substrate, through photolithography and chemical etching methods, the line pattern is transferred to the copper foil.

Soldermask Fabrication: Soldermask is applied to the copper foil, which is dried and cured to form a soldermask used to protect the line from environmental influences.

Screen Printing: Using screen printing technology, coatings such as solder and insulating materials are printed onto copper cladding boards to form the various graphics and markings required.

Heat treatment and molding: After a series of heat treatment and molding processes, the PCB reaches the required mechanical properties and dimensional requirements.

Inspection and testing: the finished Circuit Board appearance inspection, electrical performance testing, etc., to ensure that the quality is up to standard.

Application of Printed Circuit Board

As a key component in electronic equipment, printed circuit boards have a wide range of applications. The following are some typical application scenarios:

Communication field: PCB in communication equipment is used to realize signal transmission, data processing interface connection, and other functions.

Medical field: PCBs in medical equipment are used to monitor physiological parameters and control the treatment process, such as electrocardiographs and MRI machines.

Aerospace: PCBs in aerospace equipment are used to provide highly reliable electrical connections to ensure the normal operation of the equipment.

Automotive field: PCBs in automotive electronics are used to control engines, brake systems, airbags, etc. to improve the safety and performance of automobiles.

Consumer electronics field: smartphones, tablet PCs, TVs, and other consumer electronics products in the PCB are used to achieve a variety of functional modules connected and controlled.

The future development of printed circuit boards

As technology advances and market demand changes, printed circuit boards are constantly developing and innovating. Future trends in printed circuit boards include the following:

High-Density Interconnect (HDI) technology: HDI technology realizes high-density integration of PCBs through microvia processing and fine line fabrication, which reduces the size and weight of products and improves performance and reliability.

Green: With the growing awareness of environmental protection, the environmental requirements in the production process of printed circuit boards are becoming more and more stringent. The application of lead-free, halogen-free, and other environmentally friendly materials is becoming more and more widespread, while the recycling and reuse of waste Printed Circuit Boards is also being emphasized.

Intelligent and multifunctional: With the development of the Internet of Things, artificial intelligence, and other technologies, the intelligence and multifunctionality of the printed circuit board have become an important development direction. Intelligent circuit board can realize a variety of functions such as data acquisition, processing, and transmission, providing strong support for the development of intelligent devices.

5G technology: the rapid development of 5G communication technology will further promote the development of the printed circuit board industry. 5G equipment in the PCB needs a higher degree of integration and smaller size but also needs to meet the requirements of high-speed signal transmission.

Application of new materials and new processes: the emergence and application of new materials will bring more possibilities for the production of printed circuit boards. For example, new materials such as high-performance resins and nanomaterials can improve the thermal conductivity, electrical conductivity, and mechanical properties of the line. new processes such as laser direct imaging technology can improve production efficiency and line accuracy.