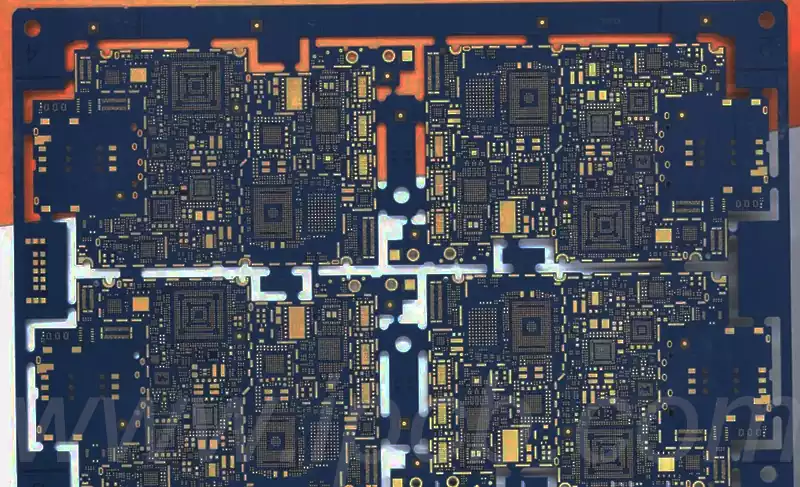

A circuit board enclosure is a material specifically designed to protect circuit boards from damage or contamination. It also enhances the mechanical strength and thermal resistance of the circuit board, ensuring that it is more robust and trustworthy. Choosing the right enclosure is an integral part of the design process as it directly affects the durability, functionality and appearance of the final product.

Based on factors such as material properties, manufacturing processes, and dimensional specifications, there are several types of pcb enclosure that can be used to protect printed circuit boards, the most common of which include:

Plastic Enclosures

Plastic is the material of choice for circuit board enclosures due to its versatility, durability and affordability. Common plastic materials are:

ABS (Acrylonitrile Butadiene Styrene) is a widely used thermoplastic favoured for its excellent strength, stiffness and impact resistance.ABS enclosures are not only lightweight and easy to mould, they are also available in a variety of attractive finishes.

Polycarbonate: An engineering grade thermoplastic, polycarbonate offers excellent impact resistance and flame retardancy for demanding applications. Although processability is good, be aware of its propensity for stress cracking.

Polyvinyl Chloride (PVC): PVC enclosures exhibit good chemical and moisture resistance, as well as high dielectric strength. It is inherently flame retardant, but has limited heat resistance.

Nylon: The nylon (polyamide) shell is abrasion- and chemical-resistant, and its mechanical strength is further enhanced by the addition of glass fillers. However, nylon is less stable under UV light.

Plastic housings can be easily moulded into a variety of shapes and colours and are easy to process and print.

Metal housings

Metal housings not only provide strong mechanical protection, but also provide effective shielding against electromagnetic interference (EMI) and radio frequency interference (RFI).

Commonly used metal materials include:

Aluminium: Aluminium is popular for its light weight, corrosion resistance and excellent thermal conductivity. Aluminium is easy to machine and surface treat.

Steel: Both cold rolled steel and stainless steel are highly durable. Steel housings provide solid protection for heavy-duty applications, but require attention to corrosion prevention treatments.

Die-cast alloys: Alloys such as zinc and aluminium can be die-cast into complex, high-precision housings with excellent dimensional accuracy and smooth surfaces.

Metal housings are ideal for rugged industrial applications, dissipating heat and protecting electronic components. Individual aesthetic customisation is possible through metal finishing and CNC machining.

Ceramic Housings

Ceramics are a high-temperature resistant material for circuit board housings. Common ceramic materials include aluminium oxide (Al2O3) and silicon nitride (Si3N4). Ceramic housings are commonly used in electronic equipment in high-temperature, high-frequency or high-voltage environments.

How to choose the right circuit board enclosure

- Grasp the circuit board specifications and characteristics

Before selecting the shell, the first task is to clarify the size of the circuit board . The first task before selecting the enclosure is to determine the size of the board, the shape of the board and its required thermal performance and other characteristics. These details will provide a strong basis for determining the type and specifications of the shell. - Selection of circuit board enclosure material

The choice of pcb enclosure material is based on the operating environment of the pcb board and the specific needs of the board. Common housing materials include metal. Plastic and composite materials. Metal shell with its excellent conductivity and thermal performance, suitable for higher thermal requirements of the circuit board; plastic shell with its lightweight. Corrosion resistance and other characteristics, suitable for ordinary environments; while the composite shell is a blend of metal and plastic advantages, suitable for specific environments. - Planning shell structure

Design shell structure, need to fully consider the installation of circuit boards. Fixed and heat dissipation and other factors. In general, the shell should have enough strength and rigidity to effectively resist external shock and vibration on the circuit board. At the same time, the shell should also be designed with efficient heat dissipation structure to ensure that the heat generated by the circuit board operation can be discharged in a timely manner. - Attention to electromagnetic shielding and dustproof and waterproof performance

For the need to prevent electromagnetic interference circuit board, should be selected with electromagnetic shielding function of the shell. In addition, if the circuit board operating environment there is dust. Moisture and other pollutants, but also need to pay attention to the circuit board shell dust and waterproof performance. - Installation and testing

After selecting and purchasing the appropriate housing, you need to follow the instructions or professional guidelines for installation and testing. Ensure that the connection between the enclosure and the circuit board is solid and reliable, and verify that the heat dissipation system is running smoothly.

The right choice of circuit board enclosure is critical, not only to protect the board, but also to enhance the performance and reliability of the device. Considering the material, structure and environmental requirements to ensure that the enclosure is a perfect match for the circuit board is the key to creating a quality electronic product.