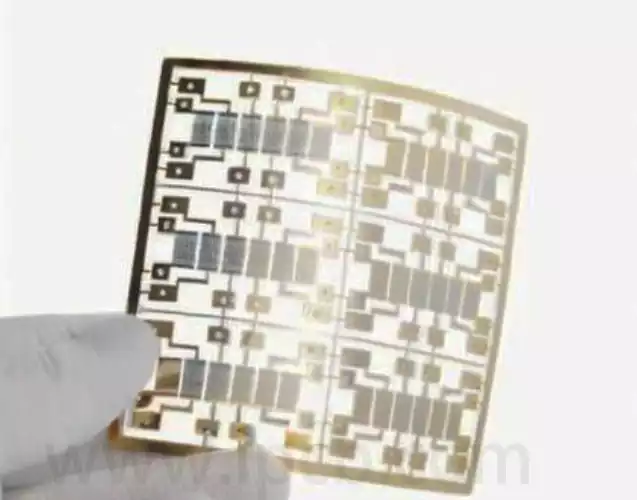

Circuit board stencil, also known as pcb stencil, is an important tool used to guarantee the quality of circuit boards and plays a key role in PCB manufacturing. It consists of a layer of metal mesh fixed on the surface of the printed circuit board, which is used to control the position of solder paste and solder to ensure the circuit board’s line accuracy and solder quality.

Classification of stencil circuit board

Frame type stencil: Frame type stencil is composed of frame and mesh, the frame is usually made of aluminum alloy or steel, and the mesh is made of stainless steel mesh structure. This stencil is suitable for various sizes of PCB substrate, easy to use and easy to replace.

Clamping stencil: Clamping stencil is a kind of stencil without frame, it is directly clamped on the PCB board for printing operations. This stencil is suitable for the production of small PCB boards, with low cost, short production cycle and other advantages.

Step Stencil: Step stencils are a type of stencil with different thicknesses and aperture ratios, which are suitable for the printing needs of electronic components of different heights and densities. This stencil can be adjusted and optimized according to the specific layout of electronic components to improve printing quality and efficiency.

Electroplated Diamond Stencils: Electroplated diamond stencils are diamond coated stencils with excellent abrasion resistance and service life. This stencil is suitable for high-precision, high-density electronic components printing needs, can effectively improve the printing quality and stability.

How to choose the right stencil circuit board for you

Specification parameters of printing plate stencil

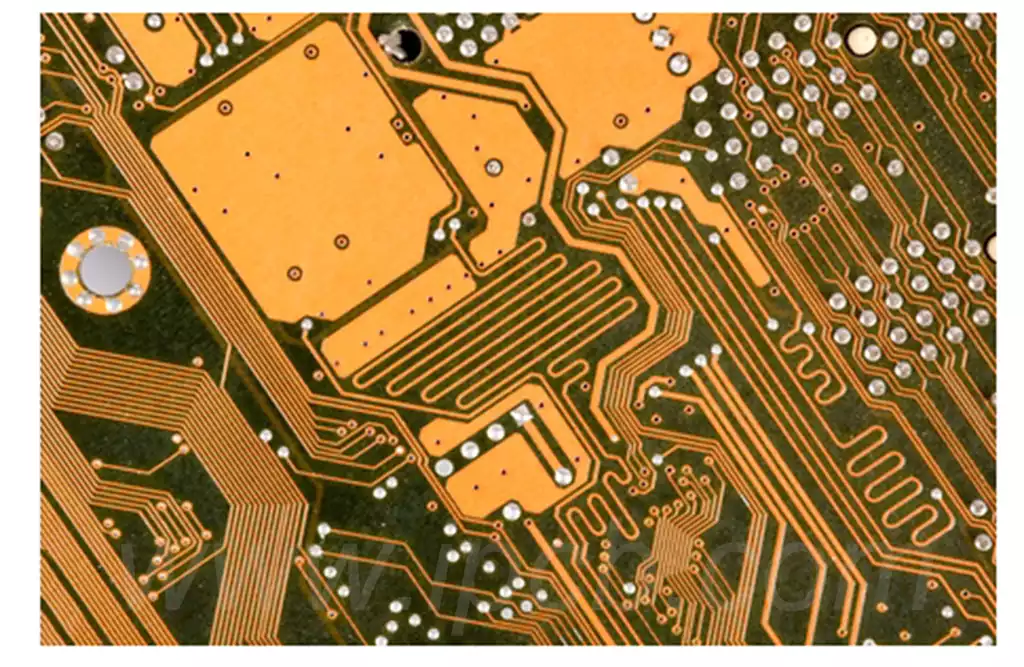

The specifications of printed circuit board stencils include thickness, aperture, tolerance and so on. Among them, the thickness is generally between 0.03mm-0.5mm, the aperture is related to the diameter of the component pins on the PCB, and the tolerance determines the processing accuracy.

When choosing a printed circuit board stencil, you need to take into account your actual needs, as well as the requirements of the PCB drawings. Generally speaking, the production of high-density PCB requires the use of thin thickness, small tolerance of the printed circuit board stencil.

Printed board stencil material

Printed board stencils are mainly made of stainless steel, copper and so on.Stainless steel has higher hardness, longer service life, and better corrosion resistance; copper has better conductivity, which can improve productivity.

How to choose the size of the printing plate stencil

Selecting the size of the printed circuit board stencil needs to correspond to the actual size of the PCB plate. Specifically, the appropriate size of the printed board stencil should be selected according to the shape of the PCB board and parameters such as pitch (line width/line spacing) to avoid errors in the production process.

Quality and Price of Printed Stencils

The quality and price of the printing plate stencil are the key factors to consider when selecting. Generally speaking, good quality printing plate stencils are more accurate and have a longer service life. The price is mainly related to the material, processing technology and other factors.

Points to note when choosing printing plate stencil

- Confirm the specification parameters of the plate stencil, select the appropriate thickness, aperture, tolerance and other parameters according to their own needs;

- Confirm the material of the plate stencil, according to their own use of the scene, choose stainless steel or copper and other materials;

- Confirm the size of the plate stencil, according to the actual size of the PCB plate;

- pay attention to the quality and price of the plate stencil, choose the more cost-effective plate stencil;

- Purchase the PCB stencil from regular manufacturers or distributors to ensure quality and after-sales service.

Stencil structure design

The structural design of the stencil directly affects the printing accuracy and efficiency of the solder paste. When designing, the following factors need to be considered:

- Mesh shape and size: The shape of the mesh should match the shape of the circuit board pads to ensure that the solder paste can be accurately printed onto the pads; the mesh size needs to be accurately calculated according to the pad size, solder paste thickness and other factors to meet the printing requirements.

- Mesh frame size and thickness: Mesh frame size should be matched with the printing machine to ensure the stability and positioning accuracy of the stencil in the printing process; mesh thickness needs to be selected according to the rigidity and flatness requirements of the stencil.

- Opening rate and mesh distribution: the opening rate can be reasonably designed to improve the printing efficiency and quality;mesh distribution needs to be optimized according to the distribution of the components on the circuit board, to avoid interference and blockage in the printing process.

Manufacturing Process Requirements

The manufacturing process of stencil is the key link to ensure its manufacturing quality. In the manufacturing process, there are the following requirements:

- High accuracy: The manufacture of stencils requires high-precision machining equipment and processes to ensure the accuracy of mesh shape, size and position. Commonly used manufacturing processes include laser cutting, electroforming and so on.

- surface treatment: the stencil surface needs to be polished, degreasing and other treatments, in order to remove surface burrs and oil, to improve the fluidity and smoothness of the printed solder paste.

- Strict testing: In the manufacturing process, the stencil needs to be strictly tested on various indicators, including mesh size, opening rate, flatness, etc.. Only stencils that pass the test can be put into use.

Use and Maintenance Requirements

In addition to the requirements in the manufacturing process, there are also the following requirements in the use and maintenance:

- Correct use: When using the stencil, it is necessary to follow the specified operating procedures to avoid overstretching,bending and other behaviors that lead to deformation or damage to the stencil.

- regular cleaning: the use of the process will be contaminated with solder paste, dust and other impurities, in order to ensure the quality of printing and extend the service life, the need for regular cleaning. Cleaning should use special cleaning agents and tools to avoid damage to the stencil.

- Proper storage: the stencil should be properly stored in a dry, clean environment to avoid deformation or damage caused by moisture, pressure and so on. At the same time, stencils should be labeled and categorized so that the required stencils can be found quickly.

Choosing the right tools, paying attention to the details of the design and manufacturing process, as well as the correct operation and maintenance, is to ensure the quality and efficiency of PCB production,stencil circuit board is an important part of this process, its accurate performance and efficient performance for the high quality of the production of electronic products to provide strong support.