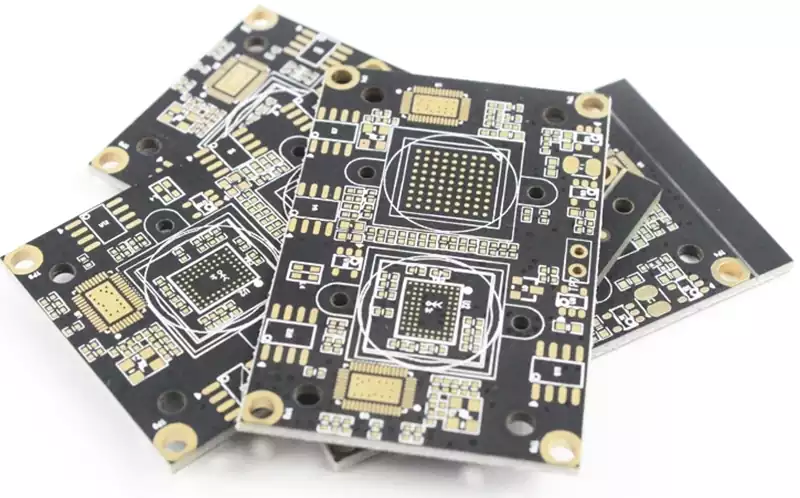

Keyboard circuit board is an important part of the keyboard, which is responsible for converting the key signals into electronic signals that are transmitted to the computer. Customizing a keyboard pcb means designing and building a circuit board that meets the user’s needs and preferences. This includes determining the layout of the keyboard, the number of keys, the connection methods, etc., and performing the corresponding circuit design and component layout on the circuit board.

Components of a Computer Keyboard circuit board

A computer keyboard PCB consists of three main parts: the processor, the scanning circuit and the matrix.

The processor, also called a microprocessor, is an electronic chip that processes computer instructions and sends information to it.It is located on the PCB inside the keyboard.The processor receives input from the computer and sends it to the scanning circuit.

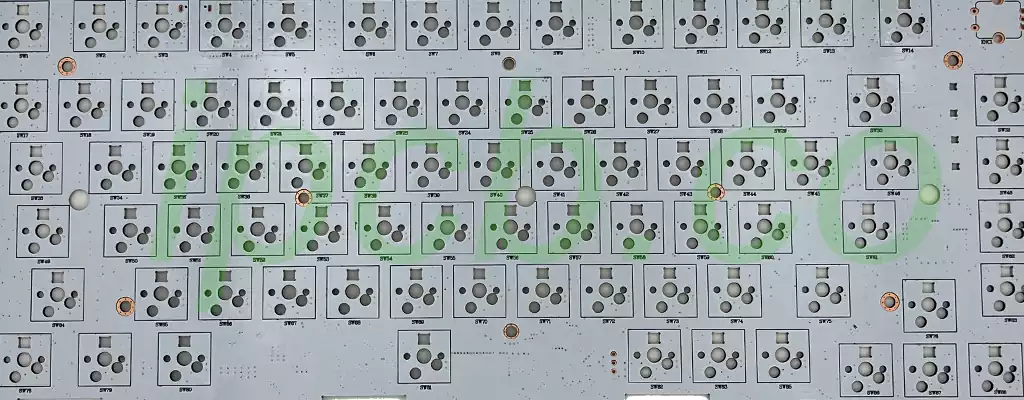

The scanning circuit is made up of a set of interconnected transistors that receive signals from the data lines that run with each key on the keyboard.When one of these lines is activated, it sends an electrical signal to the transistors within the scanning circuit. The transistors then activate switches on each key on the keyboard and send information to the processor.

The matrix is another set of interconnected transistors that receive signals from the rows and columns where each key on the keyboard is located. When one or more keys are pressed at a time, they send signals through their respective rows and columns to four additional transistors in the matrix.

The additional transistors then send signals through different paths to activate switches on each key on the keyboard and pass the information back to the processor to be converted into actions by software on the computer or mobile device.

How to choose the material and process for keyboard pcb boards

When choosing pcb board materials, the first consideration is electrical conductivity and mechanical strength.

Materials commonly used are fiberglass, epoxy and polyimide. Fiberglass is a common choice with good electrical conductivity and mechanical strength for most keyboards. Epoxy resin is a greenish-yellow solid with good insulating properties and mechanical strength for high-density circuit boards. Polyimide, on the other hand, is a high-performance material with excellent thermal conductivity, electrical properties, and mechanical strength, and is especially suitable for keyboards that are used for long periods of time and with high frequency keystrokes.

In addition to material selection, process is also one of the most important factors affecting the keyboard experience.

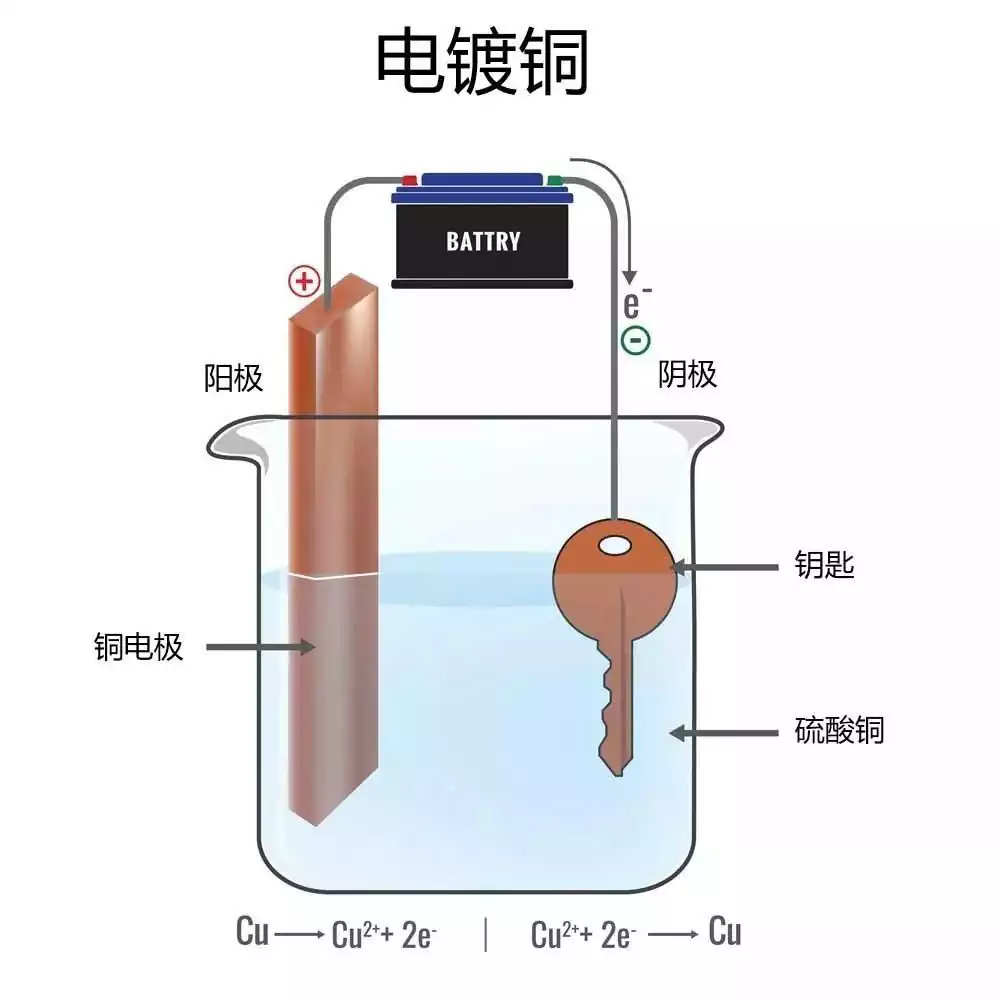

A common process is electroplating, which improves the conductivity and corrosion resistance of pcb boards. Common plating methods include metal plating, tin plating and nickel metallization. Metal plating increases the conductivity of the pcb board and provides better connectivity and reliability. Tin plating helps to improve the corrosion resistance and solderability of the keyboard, making it more stable and durable. Nickel metallization, on the other hand, provides better abrasion and corrosion resistance and is suitable for keyboards that are used frequently over long periods of time.

There are also a number of other processes that can further enhance the keyboard circuit board experience.

What is the manufacturing process of keyboard PCB design?

Keyboard PCB is the core component of a keyboard, taking on the functions of key switching and signal transmission. Its manufacturing process mainly includes the following steps:

Obtaining raw materials: mainly including copper foil, substrate, electronic components, etc.

Design the circuit: according to the product requirements, use professional software to design the circuit diagram.

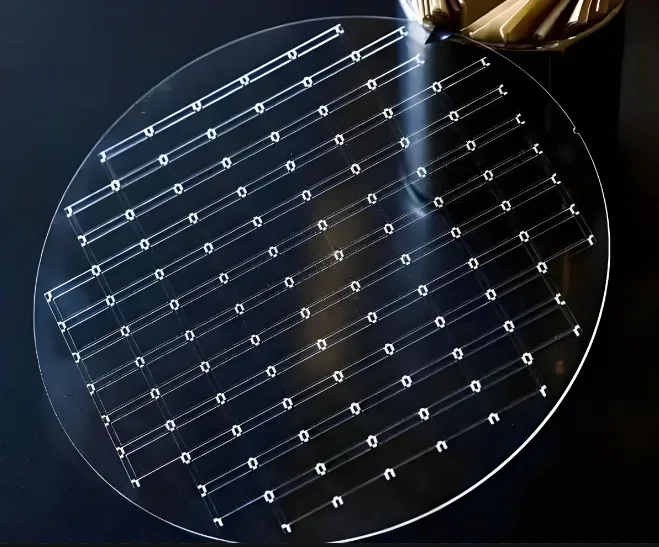

Making circuit boards: placing copper foil on the substrate, forming the required circuit graphics through exposure, development and other processes.

Etching: Utilize chemicals to etch away the unwanted copper foil to form a complete circuit.

Gong board and drilling: Precision processing of pcb substrate for mounting electronic components.

Mounting and Soldering of Electronic Components: Mount the electronic components on the PCB and make them fixed by soldering.

Functionality testing: testing of the finished product to ensure that it functions properly.

The main factors affecting the cost of customized keyboard circuit board

Design complexity: the design complexity of the keyboard circuit board is one of the important factors affecting the cost.If the customer has special requirements for the layout and function of the keyboard, which requires a complex design, then the cost will increase accordingly.

Material selection:high-quality materials have better durability and stability,but the price will be correspondingly higher.Therefore, when choosing materials, you need to weigh the balance between performance and cost.

Production process:Different production processes will have an impact on the cost of the keyboard pcb.Some high-end production processes, such as laser cutting, CNC machining, etc., can bring more delicate and beautiful products, but will also increase the cost.

Order quantity: Generally speaking, the larger the order quantity, the lower the customized cost of a single product will be. This is because mass production can reduce the manufacturing cost per unit of product.

The keyboard PCB is not only the soul of a computer keyboard, but also the vehicle for each keyboard user’s individual needs. By gaining a deeper understanding of the components of a computer keyboard circuit board, the materials and processes selected, and the manufacturing process, we can better understand and customize the keyboard to meet individual needs.