PCB and PCBA, as important components in the electronics industry, play a key role in electrical interconnection and circuit support. printed circuit boards provide the fixing and electrical connection of electronic components, while pcba, as the processing flow of printed circuit boards, completes the assembly and welding of components.

What is the difference between pcb and pcba?

PCB mainly plays the role of supporting and connecting electronic components, while PCBA is the process of integrating electronic components into a complete circuit system. They each play an integral role in the manufacture and application of electronic devices.

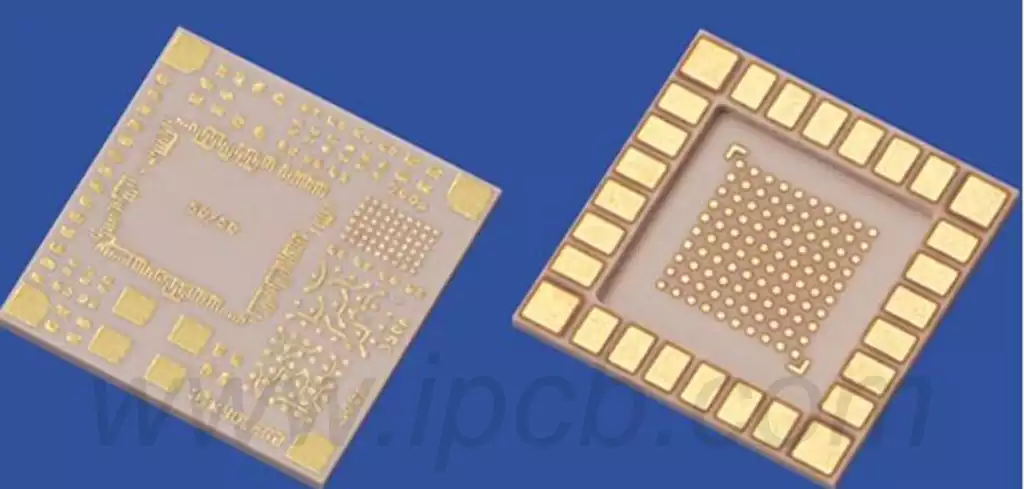

PCB, English full name Printed Circuit Board, Chinese name for printed circuit board, also known as printed circuit board. It is the support body of electronic components, but also the carrier of the electrical connection of electronic components. Since it is made using electronic printing technology, it is called a printed circuit board.

The PCB is the provider of electrical connections for pcb components and is the carrying part of the electronic original. The lines are designed to be used as a conduction tool between the original parts, and a large copper surface will also be designed as a grounding and power layer. The line and the surface are made at the same time, with high wiring density, small size and light weight, which is conducive to the miniaturization of electronic equipment.

The PCB’s substrate is made of insulating and heat-insulating material that is not easily bent, and the surface is covered with fine wiring material that is copper foil. Originally, the copper foil covers the entire board, but during the manufacturing process, part of the copper foil is etched away, leaving the part to become a mesh of fine lines.

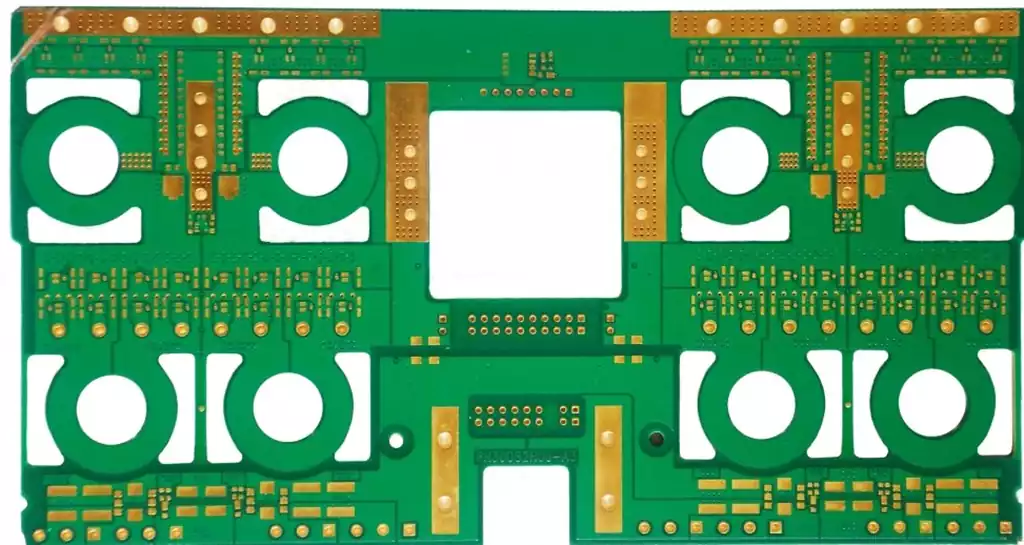

PCBs are differentiated according to the substrate material, for example, there are high frequency microwave boards, metal substrates, aluminum substrates, iron substrates, copper substrates, double-sided boards, and multilayer boards. According to the different signal layers, PCB can be divided into 4-layer board, 6-layer board, 8-layer board, etc., of which 4, 6-layer board is the most common.

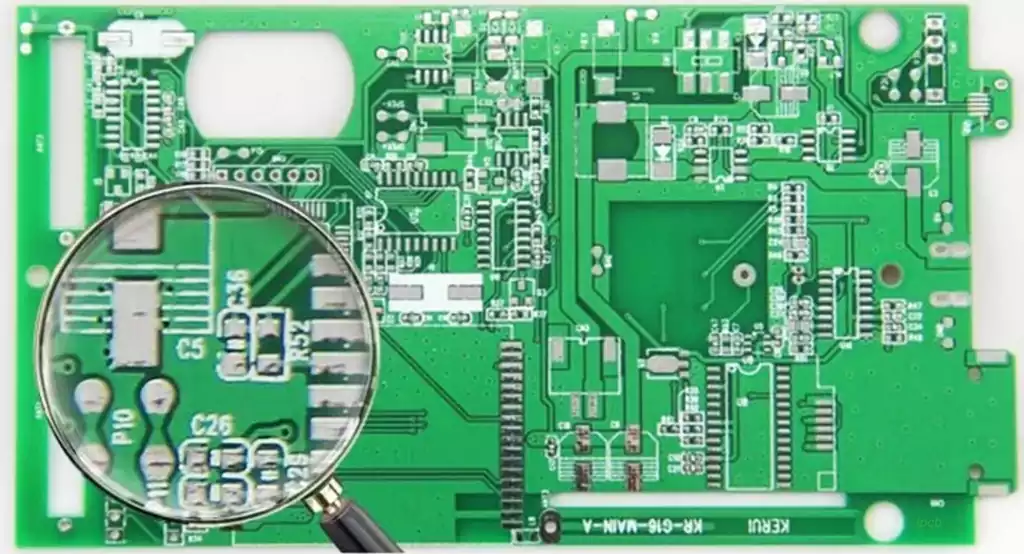

PCBA is the abbreviation of English “Printed Circuit Board Assembly”, which means printed circuit board assembly. It is a process that involves assembling electronic components, connectors, plug-ins, digital logic gates, micro-control units, etc. onto printed circuit boards, including SMT (surface mount technology) and DIP (double-sided plug-in) insertion steps to ensure that the components are correctly connected to the printed circuit boards in order to realize the function of the circuit design. PCBA is an extremely important part of all electronic product components and is widely used in a variety of electronic products, such as electrical appliances, 3C digital products , the main chassis of desktop computers, monitors , mice and keyboards , U-disks , etc., as well as network communications, Automotive electronics, military research and other industries.

pcb and pcba connection

The production process of both PCB board and PCBA includes the following major steps:

Design: Firstly, the circuit diagram of the PCB board or PCBA needs to be designed according to the requirements of the product. The designer needs to consider the layout of the circuit, the selection of components, the characteristics of the circuit and other factors.

Plate making: the PCB board or PCBA’s board is made according to the circuit diagram. This step requires the use of CAD software for plate-making design, and then use chemical etching or mechanical etching and other methods to produce the desired board.

On the pieces: the components will be automated on the pieces, this step is generally carried out using SMT technology.

Plug-in: for the need to use plug-in components, it is necessary to plug-in process, plug-in process is generally used in DIP technology.

Welding: components and PCB board or PCBA board for welding to complete the circuit connection. Generally use reflow or wave soldering technology.

Testing: After completing the welding, the PCB board or PCBA needs to be tested to ensure that the circuit works properly.

Packaging: Tested PCBs or PCBAs need to be packaged for subsequent storage and transportation.

PCB and PCBA are two indispensable links in the field of electronic manufacturing. Together they form the core part of electronic equipment, providing a solid foundation for the rapid development of modern technology.