In high-power, high-reliability electronic products, solder joint cracking remains one of the key failure modes affecting system longevity and stability. Particularly in power modules, automotive electronics, industrial control, and aerospace applications, solder joints endure prolonged thermal cycling, mechanical stress, and current surges. Compared to conventional organic substrates like FR-4, ceramic substrates demonstrate significant advantages in preventing solder joint cracking. This superiority stems not from a single factor, but from the combined effects of material properties, structural stability, and thermal management capabilities.

Superior thermal expansion coefficient matching significantly reduces thermal stress

A primary cause of solder joint cracking is thermal expansion mismatch between different materials during thermal cycling. Silicon chips typically exhibit linear expansion coefficients (CTE) of approximately 2.6–4 ppm/℃, whereas conventional organic substrates (e.g., FR-4) often possess CTEs as high as 14–18 ppm/℃. Under repeated power cycling and environmental temperature fluctuations, this substantial expansion disparity generates shear stresses at solder joints, ultimately leading to crack initiation and propagation.

Ceramic substrates (e.g., Al₂O₃, AlN, Si₃N₄) exhibit a CTE within the 3–8 ppm/℃ range, aligning more closely with silicon chips and metallisation layers. This favourable thermal expansion matching significantly reduces stress concentration at solder joints during thermal cycling, suppressing crack initiation at its source.

High rigidity and dimensional stability prevent substrate deformation-induced failure

Ceramic materials exhibit high elastic modulus and outstanding dimensional stability. During reflow soldering, high-temperature operation, or thermal shock, ceramic substrates resist warping or plastic deformation. This contrasts sharply with FR4 organic substrates, which are prone to creep or localised deformation at elevated temperatures, thereby imposing additional mechanical tensile or bending stresses on solder joints.

A stable substrate geometry ensures more controllable and uniform stress distribution across solder joints, thereby retarding crack initiation and propagation while enhancing fatigue life.

Superior thermal conductivity minimises thermal gradients at solder joints

Solder joint cracking arises not only from overall temperature differentials but is also closely linked to localised thermal gradients. Uneven temperature distribution induces microscopic stress concentrations within joints, accelerating metal fatigue.

Ceramic substrates, particularly aluminium nitride (AlN) and silicon nitride (Si₃N₄), possess thermal conductivity far exceeding that of FR-4. Their efficient thermal diffusion rapidly conducts and evenly distributes heat generated by chips, significantly reducing thermal gradients and hotspot effects in the solder joint area. This minimises thermal fatigue damage to the joint structure.

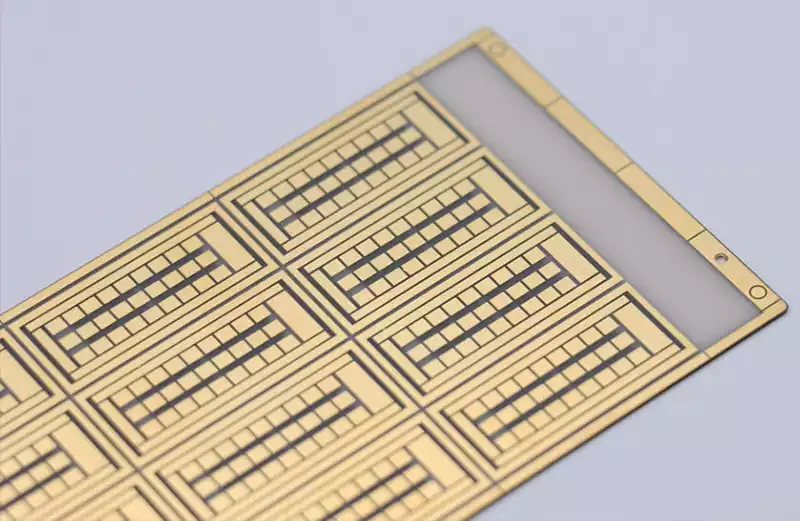

High bonding strength of metallisation layers enhances joint interface reliability

Modern ceramic substrates predominantly employ metallisation techniques such as DBC (Direct Bond Copper) and AMB (Active Metal Bonding). These processes create a metallurgical-grade bond between the copper layer and ceramic substrate, yielding interface strengths substantially exceeding those of conventional laminated organic copper-clad laminates.

The robust metallisation layer not only enhances overall structural integrity but also ensures more uniform stress transfer between solder joints and pads. This minimises the risk of interfacial delamination and microcrack propagation into the solder joints.

Long-term environmental stability mitigates material ageing effects

Solder joint cracking typically arises not from single-event failure but through gradual accumulation during prolonged service. Ceramic materials exhibit resistance to high temperatures, humidity, and chemical corrosion, avoiding moisture absorption, ageing, or performance drift characteristic of organic materials. This enduring stability maintains solder joints within a relatively predictable stress environment, thereby preserving structural integrity.

The effectiveness of ceramic substrates in preventing solder joint cracking stems not from any single property, but from their systemic advantages across multiple dimensions: thermal expansion matching, structural rigidity, thermal conductivity, interfacial bonding strength, and long-term stability.

Consequently, in high-power, high-reliability, and long-life applications, ceramic substrates have progressively become a critical foundational material for reducing solder joint failure risks and enhancing overall system reliability.