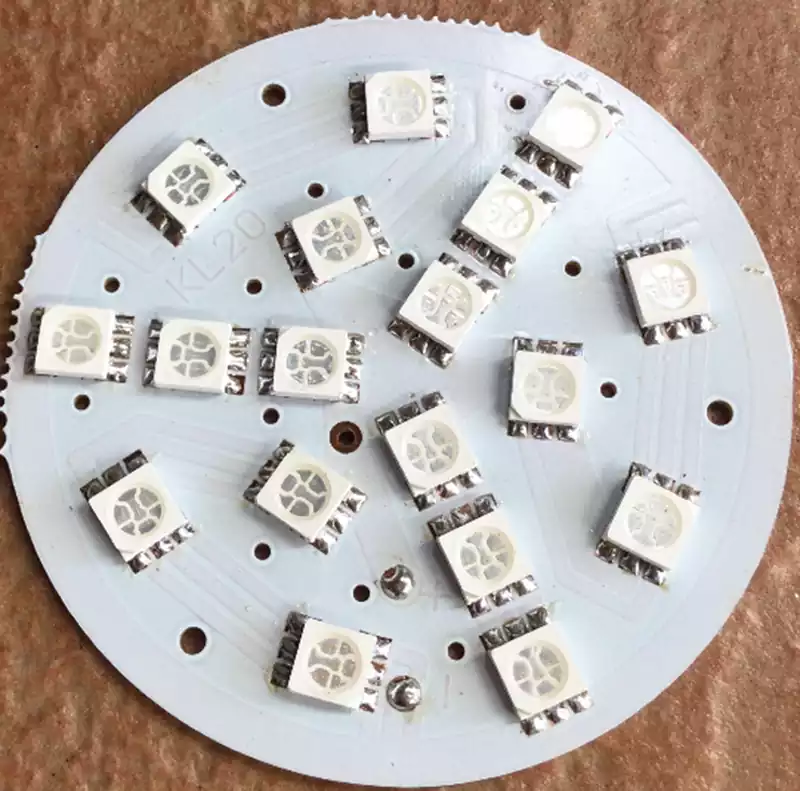

LED round pcb board is a circular printed circuit board specially designed for light emitting diodes (LEDs). It makes the overall design more compact and aesthetically pleasing by integrating the LED components on a circular substrate. This circuit board not only effectively supports the installation of LED components, but also provides them with electrical connections to ensure that the LEDs work properly.

LED round pcb board utilizes a unique circular design. This design effectively distributes light, making it more visually pleasing and harmonious.The circuit boards are usually made of a metal substrate (e.g. aluminum) to enhance heat dissipation and prevent the LEDs from overheating and affecting their service life. In addition,circular PCBs usually contain multiple LED arrays that can be flexibly configured to optimize light output and electrical connections according to specific needs.Due to their unique shape,these boards are also convenient for use in different furniture and decorative environments, providing greater design flexibility.

LED round pcb board is widely used in several industries,especially in lighting and advertising.For example, they are commonly used in indoor and outdoor lighting systems,stage lighting,billboards,and decorative lighting.In addition,LED round pcb board plays an important role in the automotive industry and are often integrated into automotive headlights and interior lighting to increase aesthetics and functionality.As LED technology continues to advance,its use in medical devices,displays and electronic equipment is also increasing,demonstrating its importance in modern technology.

Design considerations for making led round pcb board

- Determine the size and shape

First, the size and shape of the led round pcb board needs to be determined for the specific application.This involves evaluating the board’s thermal requirements and space constraints to ensure good performance is maintained in component layout and signal transmission. Select the appropriate diameter and thickness to resist the effects of mechanical stress and thermal expansion. - Circuit Layout

When designing the circuit layout,reasonable spacing between components should be ensured to avoid signal interference and heat buildup. Some layout principles should be followed, such as keeping high-frequency components close together to reduce inductance and electromagnetic interference, and separating high-power components from low-power components. Layout also needs to consider the pin direction of components, signal flow direction and shorten the length of connecting wires. - Thermal design

Led roound pcb board is often used for light-emitting diodes (LEDs) and other heat-generating components installed, so the design must take into account the heat dissipation channel. Heat can be effectively managed by adding heat sinks or using aluminum substrates so that the LEDs can operate at a safe temperature to avoid overheating. - Selection of suitable materials

The choice of material is critical to the thermal conductivity and electrical characteristics of the circuit board. Aluminum-based circuit boards are widely used for their excellent thermal conductivity, while FR-4 electronic grade materials are suitable for general purpose applications. Ensure that the material selected meets current and voltage requirements as well as durability under environmental conditions. - Drawing circuit diagrams

When designing circuit diagrams, ensure that power management, signal processing, and connection logic are correct. In addition, the layout of power and ground wires should be as wide and low impedance as possible to provide good return paths and avoid electromagnetic radiation problems caused by loop area. - Soldering and Assembly

The soldering process is also very important. Standard soldering procedures should be followed to ensure the quality of the solder joints. At the same time, attention should be paid to the position and polarity when integrating components to ensure that the circuit works properly. Good soldering and assembly can avoid subsequent failures and damage. - Production and Testing

Finally, adequate testing, including electrical testing and physical inspection,should be performed after the circuit board design is completed to ensure the reliability and functionality of the circuit. Identifying problems in advance helps to make necessary modifications and optimizations before production to improve production yields.

Choosing the right electronic design automation (EDA) software is crucial when creating circular circuit boards. The following are a few recommended EDA software with good features and ease of use for circular PCB design.

- KiCad

KiCad is a free and open source EDA software with powerful features and flexible design capabilities. Users can easily draw circular graphics and perform PCB layout and circuit simulation. Meanwhile, KiCad supports multiple output formats to meet different production needs. - Litron EDA

Litron EDA is a domestic design tool for electronic engineers,offering permanent free use.The software supports a variety of PCB design functions,including the ability to generate circular circuit boards.Its user-friendly interface and rich features make the design process more efficient. - Altium Designer

Altium Designer is a powerful and professional EDA tool that supports complex PCB design,including circular circuit boards.Although it is a paid software, its powerful design and simulation features make it very popular in the industry and suitable for design projects that require high accuracy and performance. - Protel

Protel is a classic PCB design software that supports the design of various circuit boards,including circular circuit boards. It has an intuitive user interface and a wealth of features to assist with fabrication and wiring, making the design process smoother and more efficient. - Garritron EDA

Garritron EDA is designed for the Chinese market and is especially suited to the needs of local users. It supports circular PCB design and provides convenient online collaboration features, which is ideal for teamwork.

Each of these EDA software programs has its own characteristics, allowing users to choose the most suitable tool for their specific needs.

LED round pcb board is increasingly used in modern lighting and electronic devices, and their unique design and superior heat dissipation performance make them ideal for many industries. A variety of factors, from design considerations during fabrication to applicable electronic design automation (EDA) software, combine to determine the performance and functionality of such circuit boards. In the future, as LED technology continues to evolve and innovate, circular PCB boards are sure to show their potential in more areas, providing users with more efficient and aesthetically pleasing lighting solutions. Choosing the right design software and raw materials will undoubtedly further promote the development of its applications, providing reliable support for a variety of lighting needs.