FR-4 fixture, its core material is FR-4 glass fibre board, which is a composite material with epoxy resin as the binder and electronic grade glass fibre cloth as the reinforcing material. This material not only has high mechanical strength and stable dielectric constant, but also maintains excellent electrical insulation performance under high temperature and high pressure environment.According to the test, the dielectric strength of FR-4 material can be as high as 35kV/mm, and the heat distortion temperature can be up to 130℃ or more, these data undoubtedly proves its excellent performance in the field of electronic testing.

‘FR-4’ is a flame-resistant material grade code, which means that the resin material must be able to self-extinguish after combustion state of a material specification, it is not a material name, but a material grade, so the general circuit boards used in the FR-4 grade material has a very wide range, but most of them are the so-called four-function (Tera-Function) epoxy resin plus filler (Filler) and glass fibre composite materials. The so-called four-function (Tera-Function) epoxy resin plus filler (Filler) as well as glass fibres made of composite materials.

The mechanical properties, dimensional stability, impact resistance and humidity resistance of fr4 epoxy board are higher than paper substrate. It has excellent electrical properties, high working temperature, and its own performance is less affected by the environment. In the processing technology, than other resin glass fibre cloth substrate has great superiority. These products are mainly used for double-sided PCB, with a large amount. Epoxy glass fibre cloth substrate, the most widely used product type FR-4, in recent years, due to the electronic product installation technology and PCB technology development needs, and the emergence of high Tg fr4 products.

FR4 material electrical properties

1.Dielectric Constant (Dielectric Constant, Dk): FR4 material dielectric constant is usually between 4.0 and 5.0, the specific value is affected by frequency and temperature. A lower dielectric constant helps to reduce signal delay and crosstalk, improving the overall performance of the circuit.

2.Dielectric loss angle tangent value (Dissipation Factor, DF): FR4 dielectric loss angle tangent value is generally below 0.02, the lower the value, indicating that the material’s electrical performance is better, suitable for high-frequency applications.

3.Insulation Resistance (Insulation Resistance, IR): The insulation resistance of FR4 materials is usually between 106 and 109 Ω, which means that it can effectively prevent leakage while maintaining high insulation.

4.Breakdown Voltage (Dielectric Strength): The breakdown voltage is usually above 20kV/mm, reflecting the material’s ability to withstand high voltage environments.

5.Temperature coefficient (Coefficient of Thermal Expansion, CTE): FR4 CTE is generally (55-60) ppm / C, suitable for combining with other materials (such as copper) to reduce the stress and deformation caused by thermal expansion.

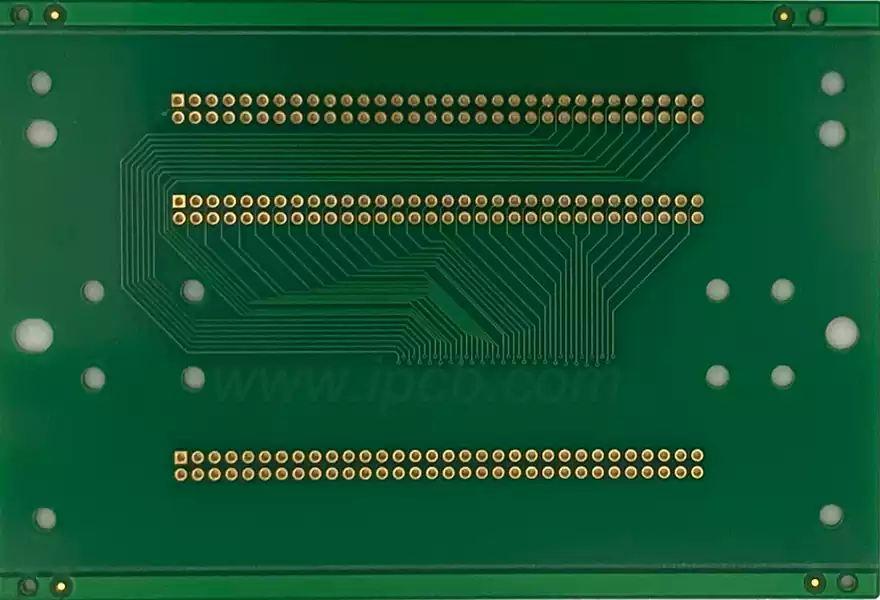

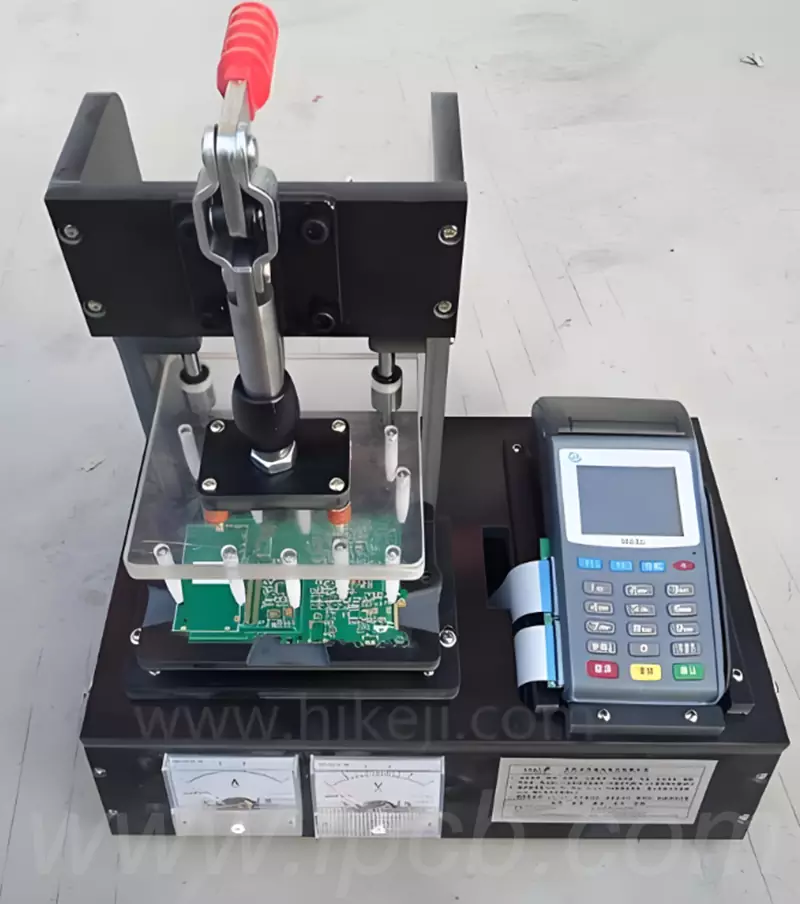

In terms of processing,FR-4 fixture has great superiority over glass fibre cloth substrates of other resins. It can be customised to meet different testing needs, such as adding test points and optimising test paths, which further improves testing efficiency and accuracy.At the same time,the FR-4 fixture also has good flatness and surface finish,which makes it ideal for precision machining and manufacturing,enabling precise positioning and testing of individual components on the motherboard to ensure that every detail meets the design requirements.

The versatility and applicability of FR-4 fixture is especially important today as electronic products become increasingly smaller and more precise. For example, in smartphone motherboard testing,FR-4 fixture can accurately position and test each component on the motherboard to ensure that every detail meets the design requirements.At the same time,its good processing performance allows the test stand to be customised according to different testing needs,such as adding test points,optimising test paths,etc.,which further improves testing efficiency and accuracy.

With its excellent performance,wide range of applications and reliable safety, FR-4 fixture plays an irreplaceable role in the electronics industry. With the continuous development and innovation of electronic technology, FR-4 fixture will continue to provide powerful support for testing and quality assurance of electronic products with its unique charm.