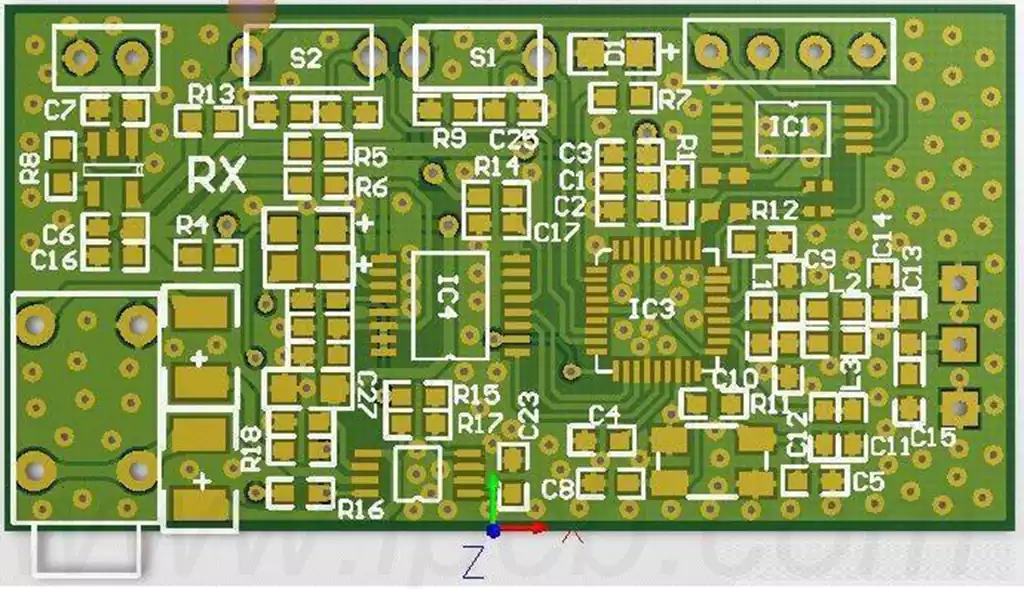

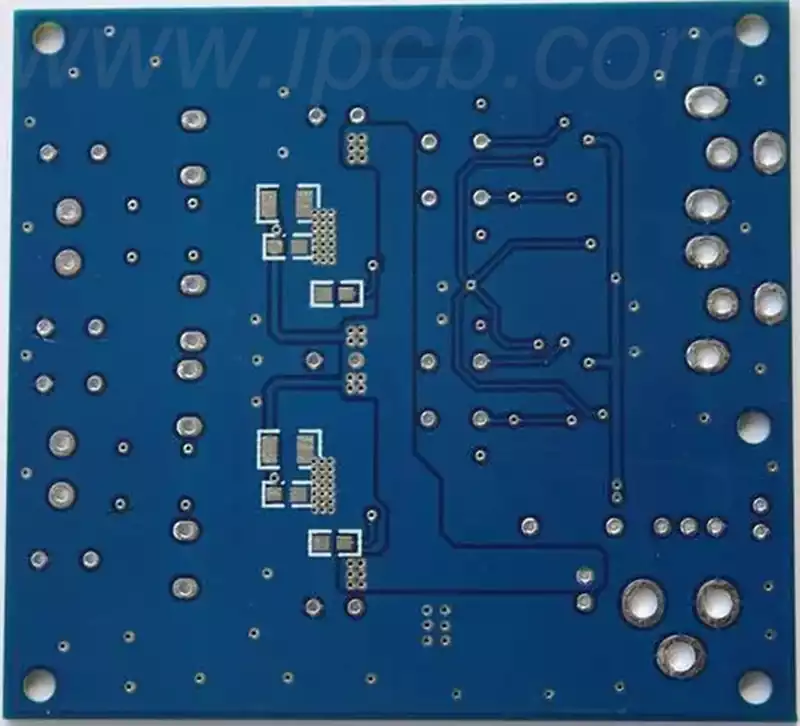

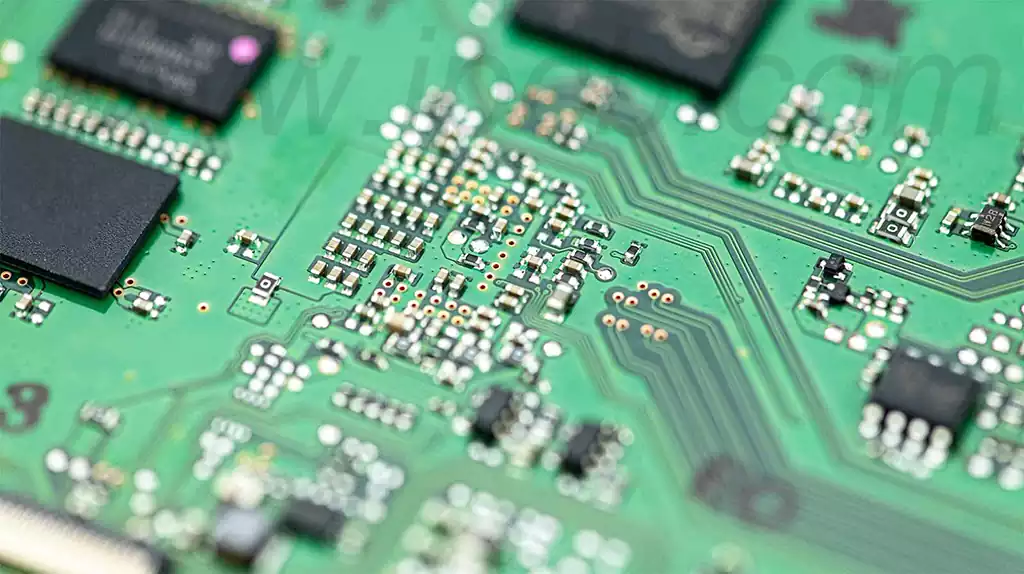

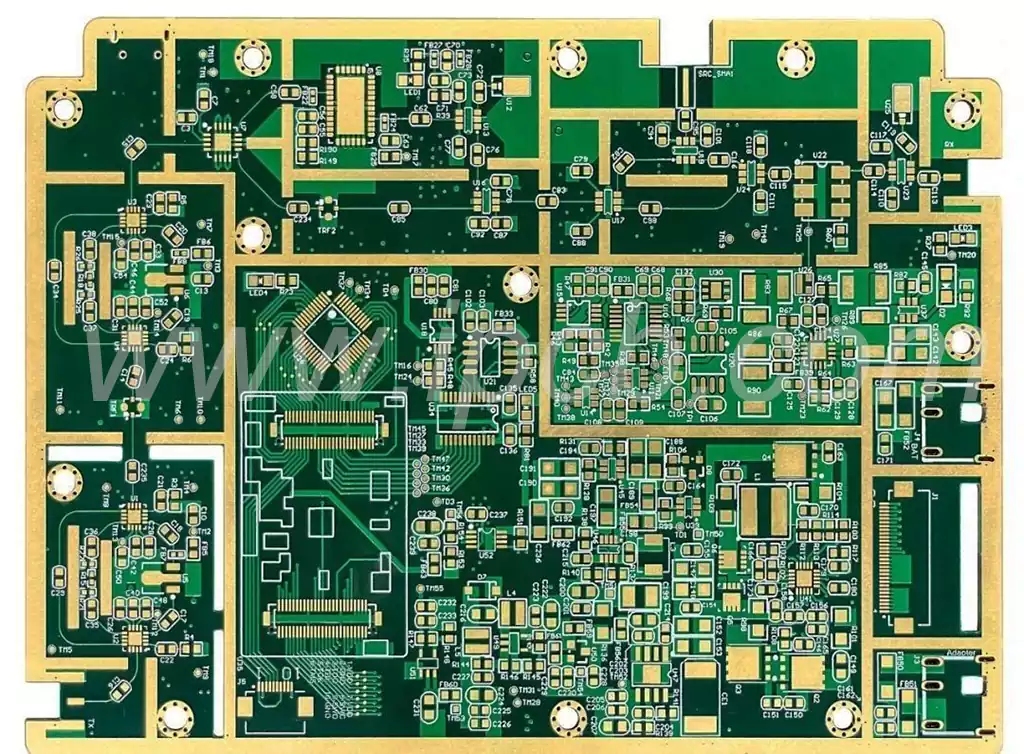

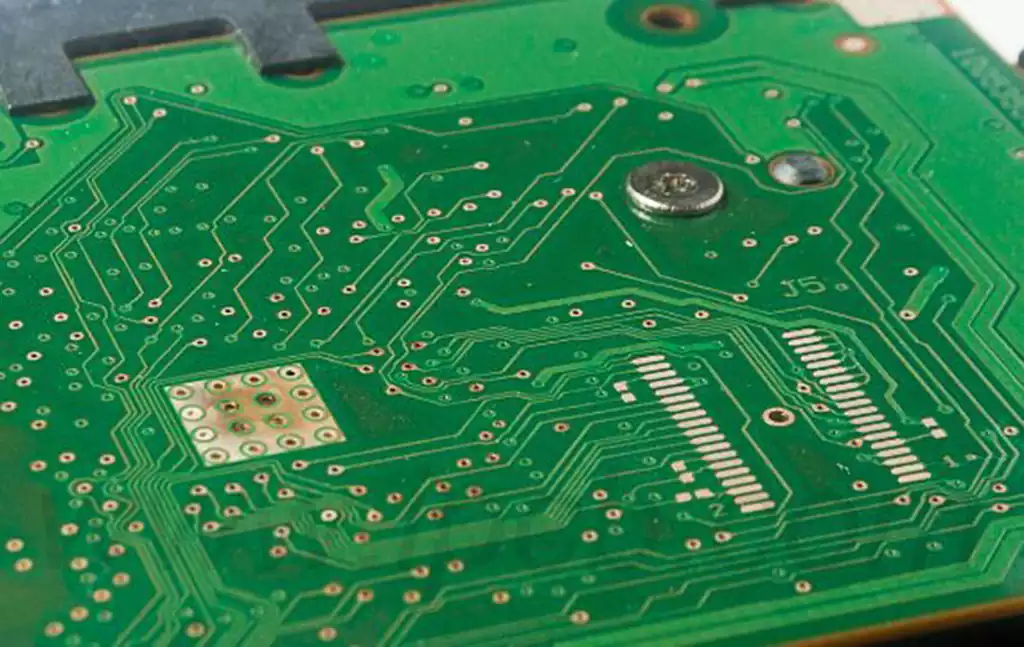

RF PCB Stackup Design Overview

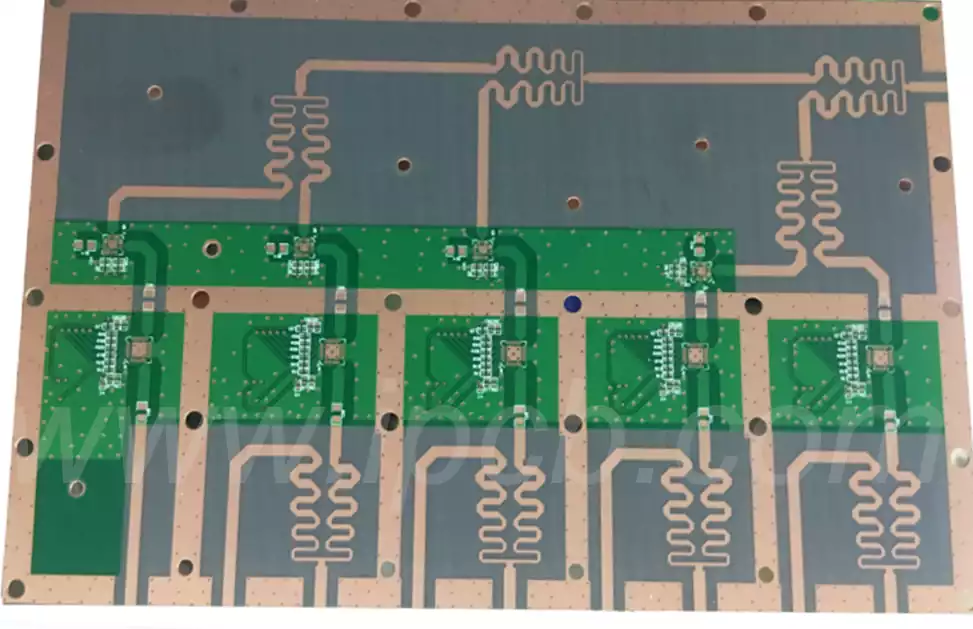

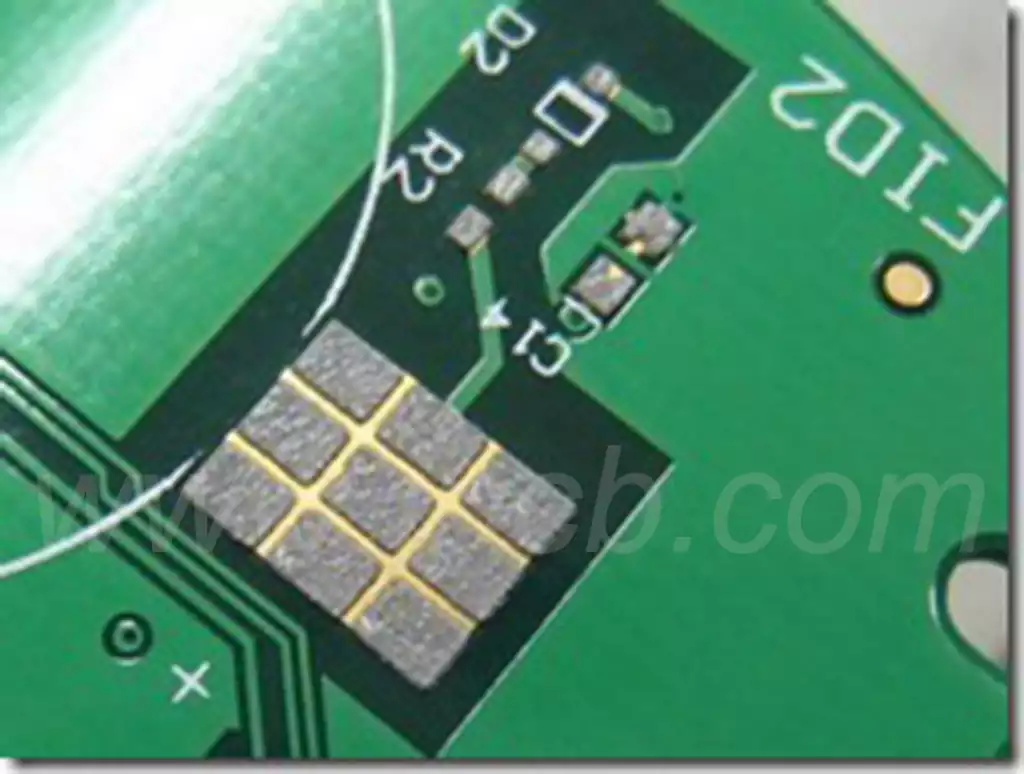

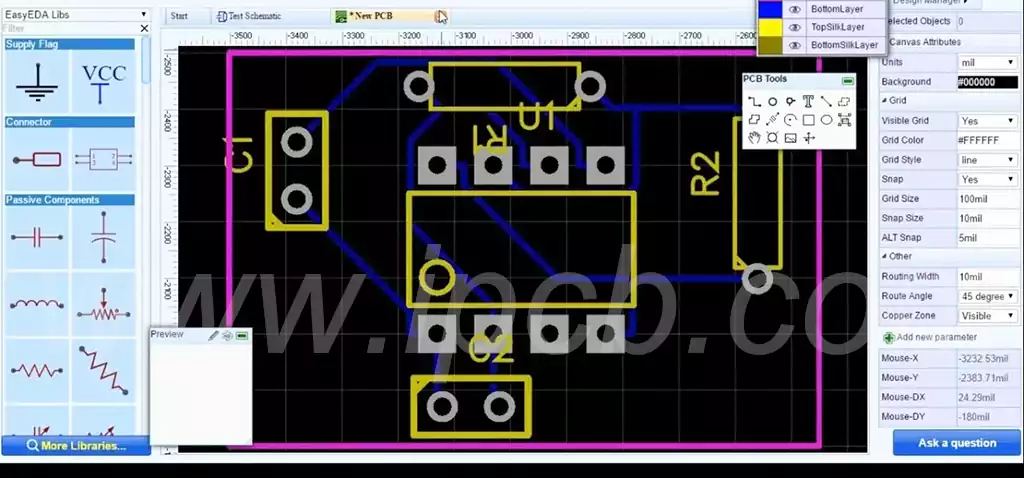

RF PCB stackup involves combining multiple board layers in a specific order and structure to form a complex circuit board. This structure not only accommodates the different functions of the circuits, but also ensures that interference between components is as low as possible and signal transmission is as stable as possible in the presence of […]