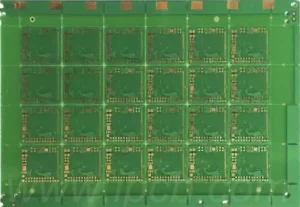

PCB Circuit Board Layer Structure

PCB circuit board infrastructure is equivalent to a building’s foundation and framework, which consists of four main layers: top layer (Top Layer), bottom layer (Bottom Layer), inner layer (Inner Layer)

Printed circuit board switches

What is printed circuit board switches?Printed circuit board switches is an electronic component used to control circuit on/off, function selection, etc. It is one of the more common components on

PCB Etching Process Essentials

In the PCB circuit board printing process, the transformation of a bare board into a finished product with clear circuit graphics requires a series of sophisticated physical and chemical reactions,

The central role of Photoresist pcb boards

Photoresist pcb boards are printed circuit boards manufactured using photoresist technology.The photoresist used in Photoresist pcb boards is a light-sensitive material that is usually applied to the surface of the

Impact and selection of active high frequency components

Active components are key components in electronic circuits that can be powered from an external source to perform functions such as signal amplification, conversion, and generation. Active high frequency components

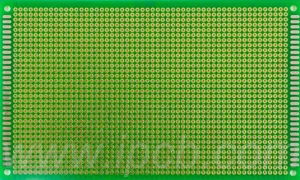

What is a protoboard?

What is a protoboard?A protoboard, also known as a ProtoType board, is essentially an early sample of a product that is designed to test a design idea and see if

Crazing pcb causes and prevention

Crazing pcb is the phenomenon of cracks or breaks in a circuit board, which can lead to impaired functionality or even complete failure of the board. The causes of crazing

How to choose the right pcba process

Selecting the right PCBA process is a strategic decision that can have a decisive impact on product quality, productivity and cost-effectiveness. In the face of a wide range of process

Impact of the HASL process on PCB Board

The tin spraying process, also known as hasl, is a long-established technology for PCB (Printed Circuit Board) surface treatment. The process starts by immersing the PCB in molten solder, which

How to Make a Breadboard Permanent

When a circuit design has been tested many times and confirmed to be feasible, it is necessary to consider how to make the breadboard permanent to ensure the stability and

Application of board electronics with holes

A board electronics with holes is a substrate used for the layout of electronic components and its function is to connect electronic components. It is a design element on a

Selection and Importance of circuit board enclosure

A circuit board enclosure is a material specifically designed to protect circuit boards from damage or contamination. It also enhances the mechanical strength and thermal resistance of the circuit board,

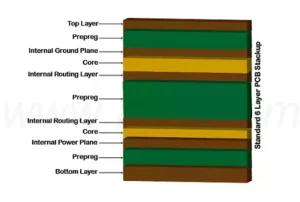

6 layer pcb stackup design

A 6 layer pcb stackup structure is a design in which six layers of conductive and non-conductive materials are stacked together during the circuit board manufacturing process to achieve complex

Selection of 96% and 99% alumina ceramic substrate

Alumina ceramic substrates consist mainly of a white amorphous powder commonly known as aluminium oxide, or simply Al2O3. It has a density of between 3.9 and 4.0 g/cm3, a melting

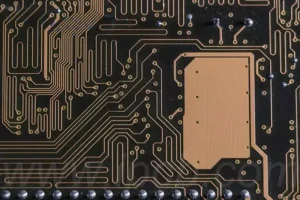

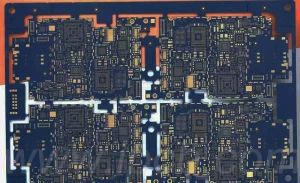

IC Board Component Layout Optimisation

As a core component, the design and layout of an integrated circuit board (IC board) has a direct impact on the performance, reliability, and productivity of the device.The layout of

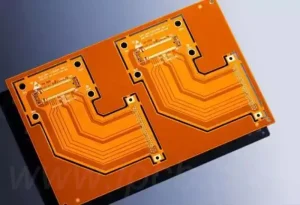

Flexible board moulding process selection and application

The choice of moulding process for flexible board directly affects product quality and production efficiency. According to the product demand, accuracy requirements and production volume, manufacturers need to reasonably select

Flexible board vs. rigid pcb and their cost impact factors

Flexible board, is the so-called flexible circuit board, in fact, also belongs to a kind of printed circuit boards, but with the traditional printed circuit boards and has a great

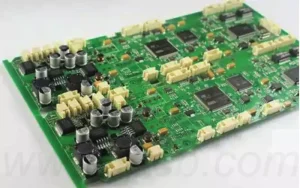

Classification and Manufacturing Challenges of IC Board

IC board, i.e. packaging substrate, is a kind of circuit board used to carry chips, belongs to a branch of PCB, has the characteristics of high density, high precision, high

Automotive circuit board PCBA manufacturing and technology

As the core component of automotive electronic system, the manufacturing quality of automotive circuit board (PCBA) is directly related to the performance and safety of the whole vehicle. Due to

High speed pcb sheet in PCB manufacturing

High speed pcb sheet has the characteristics of low dielectric constant and low dielectric loss, which helps to significantly reduce the energy loss and distortion during the signal transmission process,

Key Elements of RF Circuit Board Design

Although the field of radio frequency (RF) circuit board design is still full of unknowns, there are a number of guiding principles that can be followed. However, the main challenge

Why do PCB circuit boards choose more even layers?

PCB circuit boards are divided into single-sided, double-sided and multilayer type, which the number of layers of multilayer boards are not strictly limited, there are more than 100 layers of

PCB lamination process

PCB lamination is a key process step in the manufacture of multilayer printed circuit boards (PCBs). In this process, multiple thin, pre-processed circuit board layers (including copper foils, insulating substrates,

Capacitors And Resistor Enhanced EMS and ESD Protection

Agnetic environments and the control of interference with other equipment. ESD protection is the key to ensure that the equipment is not damaged in the electrostatic environment. This article will