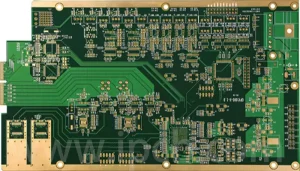

Types and cost of hdi pcb

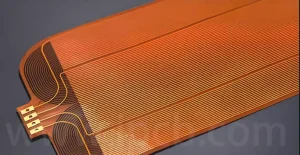

HDI PCB definition, High Density Interconnect Board, is a circuit board with high line distribution density using micro-blind/buried hole technology. It is able to achieve higher line density and finer

Application and Manufacturing of Thermistors in Circuit Boards

On a circuit board, RT usually stands for Thermistor, a component that is extremely sensitive to temperature. The resistance value of a thermistor changes significantly with temperature, so by measuring

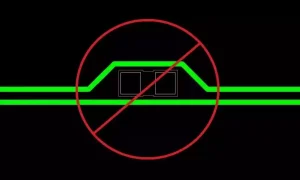

PCB Test Point Layout

PCB test points may look like just some pads or exposed copper skins, but their role in the entire production, debugging, testing and repair process is very critical. If the

Glass PCB Technology and Its Future in High-Performance Electronics

With the development of cutting-edge technologies such as 5G, artificial intelligence, and the Internet of Things, electronic products have put forward higher requirements for high-frequency, high-speed, low-loss, and low-dielectric circuit

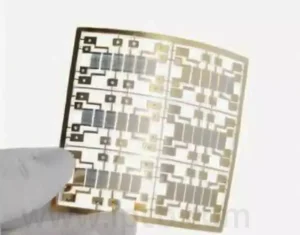

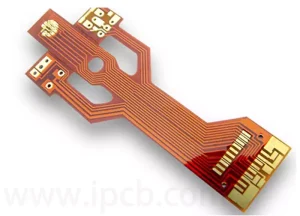

Future challenges and application for transparent flexible pcb

A transparent flexible PCB is a pcb board that can be bent and has a certain degree of flexibility without affecting its functionality. It is made of flexible materials such

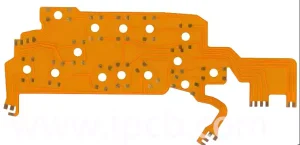

Key points and strategies for soldering flexible circuit board

FPC flexible circuit board is widely used in modern electronic products due to their thin, lightweight and bendable characteristics. However, its unique physical properties also bring many challenges to the

Deformation and Delamination Prevention in Flex Board Manufacturing

In the production of flex board, material deformation and delamination are important factors affecting product quality. In order to avoid such problems, the following detailed coping strategies can be adopted:

Key considerations and applications for high speed digital pcb

High speed digital pcb is circuit boards that can support high speed digital signal transmission, and are usually used in scenarios where the frequency of digital logic circuits reaches or

mSAP and SAP Technology in Next-Gen IC Substrate Manufacturing

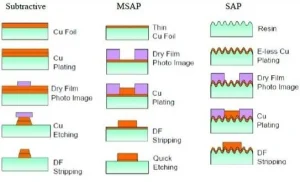

Process principles and differences between SAP and mSAP In traditional PCB manufacturing, the most commonly used method is the subtractive process, which is to remove unnecessary copper from the entire

Differences between leadless chip carrier and leaded chips

Leadless chip carrier refers to a chip substrate material that does not contain lead. Traditional chip carriers often use leaded materials because leaded materials have high plasticity and are easy

Common defects in pcb board assembly processing

PCB board assembly processing, there may be a variety of defects, these defects can be categorised as the following major aspects, designed to improve product quality and reduce the defective

Technology and Challenges of AMB Ceramic substrate

Ceramic substrate in accordance with the process points there are many kinds of, in addition to direct bonding copper (DBC) method, direct copper plating (DPC) method, laser activated metal (LAM)

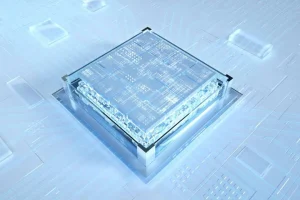

What is a chipset and what does it do?

What is a chipset? A chipset is a processor that consists of multiple chips. Each chip in a chipset may be produced by a different manufacturer. These individual chipsets are

Process analysis and industry value of CSP Package

In just a few decades, electronic products have been developing towards miniaturization, multi-function and high performance. Chip packaging is a key link to achieve this goal. Among the many packaging

Comparison of ceramic substrate and normal pcb

Ceramic substrates and PCBs play an important role in the electronics industry, each with unique material properties, manufacturing processes and application areas. Ceramic substrate is a ceramic material made of

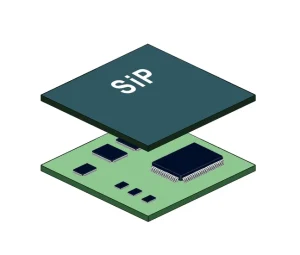

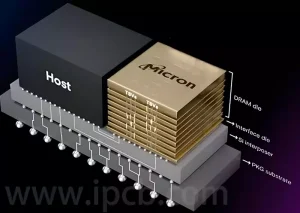

Application and Prospect of SIP Package

System in Package (SIP) is a packaging method that integrates multiple semiconductor chips and passive components vertically or horizontally in a single package module. Compared with traditional multi-chip packaging (MCM),

What is dual inline package?

What is dual inline package? Dual inline package (DIP) is a type of integrated circuit package whose main feature is that the integrated circuit chip is mounted on two parallel

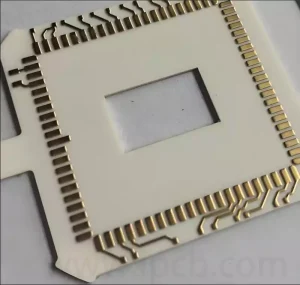

Production considerations for ball grid array socket design

The ball grid array socket is an adapter that allows for pluggable mounting without directly soldering BGA-packaged integrated circuits (ICs) to the test substrate. By connecting the solder balls of

Camera pcb board design

The design layout of a camera pcb board is a central aspect of ensuring camera performance, reliability and stability. An optimised layout can effectively reduce signal interference, improve signal integrity,

Introduction to Camera PCB Board

The camera motherboard, also called the camera pcb board, is one of the core components inside the camera and contains the camera’s processor. Memory. Interface chip. Sensor control chip and

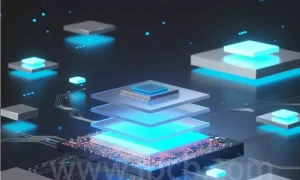

Process Principles and Development of Hybrid Bonding Technology

Hybrid Bonding is an advanced IC packaging technology used to achieve high-density, high-performance interconnections between different chips. The key feature of this technology is to replace the traditional bump or

Hybrid bonding technology process and application

Hybrid bonding is an emerging packaging technology that combines the features of inter-chip bonding and intra-chip bonding. It utilises different bonding techniques to achieve interconnections between wafers and package substrates

FPC Bonding Technology Process

FPC Bonding (Flexible Printed Circuit Board Bonding) is a technology that electrically and mechanically connects flexible circuit boards (FPC/FPCB) to other electronic components, rigid circuit boards (PCBs), or components such

Differential Signal Cabling Design and Optimisation

Differential signal line is mainly the difference between the traditional signal line corresponds to a ground line signal transmission mode, differential signal transmission is mainly two lines on the signal