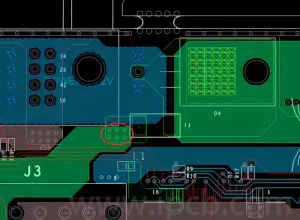

HDI board Design

HDI circuit boards are highly integrated printed circuit boards with high density, miniaturization, and light weight, which can significantly improve the performance and functional density of electronic products. HDI board

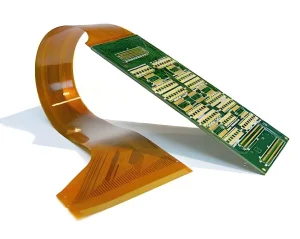

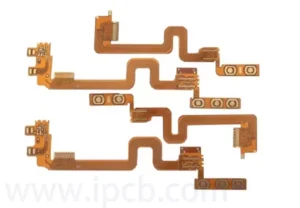

BGA packages on flexible circuit boards

BGA packages is solder ball array package, is an integrated circuit using an organic carrier board packaging method. With the continuous development of society, in order to meet the demand

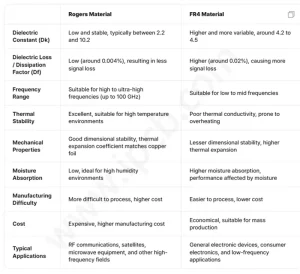

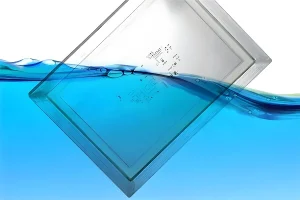

Why is Rogers material not FR4?

Rogers material is a specialised laminate used in the manufacture of high frequency, high performance Printed Circuit Boards (PCBs) and is manufactured by Rogers Corporation. Rogers materials typically do not

The role of pcb Prepreg

PCB prepreg is a soft material, similar to the black tape, also called ‘semi-glue’ or ‘film’, commonly used in the production of circuit boards. In the PCB PP is sandwiched

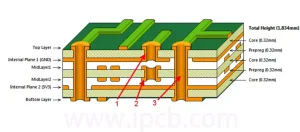

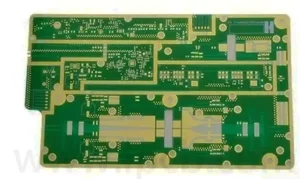

PCB circuit board Layer Stacking Structure Optimisation Strategies

The laminated construction of PCB circuit boards refers to the stacking of multiple layers of circuit boards together to form a single structure. Electronic components can be arranged on each

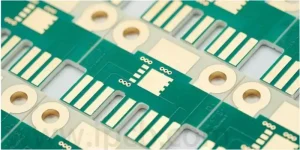

Advantages and Processes of Rogers Ceramic PCB

Rogers ceramic pcb is a kind of circuit board using ceramic material as the substrate, which has the advantages of high thermal conductivity, high insulation, corrosion resistance and high temperature

Rogers RO4003C Substrate Performance and Design Points

Rogers RO4003C substrate is known for its dielectric constant Dk of 3.38+/-0.05 and low dielectric loss Df of 0.0027 at 10 GHz. It is a unique glasscloth-reinforced, ceramic-filled hydrocarbon composite

PCB plating hole filling process

PCB plating to fill vias is a treatment performed to connect different layers of circuits during the manufacturing process. In the manufacturing of High Density Interconnect (HDI) boards and multilayer

Relationship between pcb circuit board line width and current-carrying capacity

In electronic circuit design, pcb circuit board line width is closely related to its current carrying capacity. Wire width directly determines the cross-sectional area of the wire, thus affecting the

Advantages of through hole assembly

Through-hole assembly, also known as through-hole technology, is a mounting method for electronic components. It consists of inserting components into existing holes in printed circuit boards (PCBs) using the component’s

Innovation Through PCB Flex Rigid Technology

As electronic devices continue to develop towards miniaturization, lightness, and multi-function, the limitations of traditional rigid circuit boards and flexible circuit boards have gradually emerged, and they cannot fully meet

Multilayer RF PCB Design Essentials

A radio frequency circuit board (RF PCB) is a type of circuit board specifically designed to handle high frequency and radio frequency signals. Compared to ordinary PCBs, RF PCBs have

Advantages and Manufacturing Challenges of Heavy Copper Flex PCB

Heavy copper flex PCB refers to circuit boards with thicker copper layers in the flexible circuit board, which are usually between 100 and 400 microns thick, far exceeding the 35

Reliability of automotive pcb assembly

With the rapid development of automotive electronics technology, automotive PCB assembly as a key electronic manufacturing link, its reliability is directly related to the safety and performance stability of the

Differences between automotive circuit boards and ordinary

Automotive circuit board, full name of automotive printed circuit board, is a kind of electronic products using printing technology to print the copper foil line on the insulated substrate. It

Automotive PCB assembly and development outlook

Automotive pcb assembly is the process of assembling automotive printed circuit boards, which has more stringent quality requirements than PCBA in other fields. This is mainly because the automotive electronic

Printed circuit board single-sided, double-sided and multilayer PCB differences and applications

Printed circuit boards are the bearers of electronic components, which provide a master for connecting the various components in a circuit. Structurally, PCBs are mainly classified into single-sided, double-sided and

Flex PCB Edge Connectors Explained

A flex pcb edge connector is an electrical connector designed for flexible printed circuit boards (FPCs) to provide a reliable electrical connection between the circuit leads of a flexible circuit

Flex pcb thickness selection guide

The flex pcb thickness varies depending on the material, manufacturing process and application requirements, typically ranging from 0.1mm to 1.6mm. Choosing the right thickness is critical to ensure product performance

Common Defects in Printed Circuit Boards

Printed circuit board (PCB) as a core component of modern electronic equipment, its quality and reliability of the performance of the entire electronic system plays a vital role. However, during

The Solder Paste Stencil Behind SMT Quality

In the entire process of SMT, precise printing of solder paste is the first step to achieve high-quality welding. To achieve this goal, a widely used and crucial tool is

PCBA mass production common problems and solutions

In the PCBA mass production process, due to the expansion of production scale and process complexity increases, often encounter some common problems. The following will explore these issues in depth

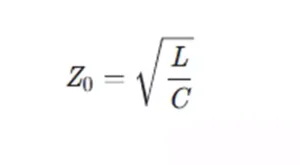

Difference and Calculation of Characteristic Impedance and Impedance

Characteristic impedance, also known as features impedance, is the pure resistance of a circuit or transmission line per unit length when the frequency tends to infinity. It is an inherent

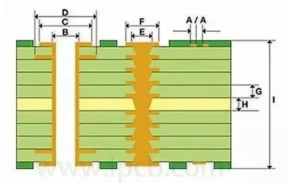

HDI pcb stackup structure and rational design

HDI PCB is usually manufactured using the stackup method, the so-called ‘stackup’ refers to the formation of complex multilayer structures through the stacking and compression of multiple layers of circuit