Key Considerations and Strategies for High Speed PCB Design

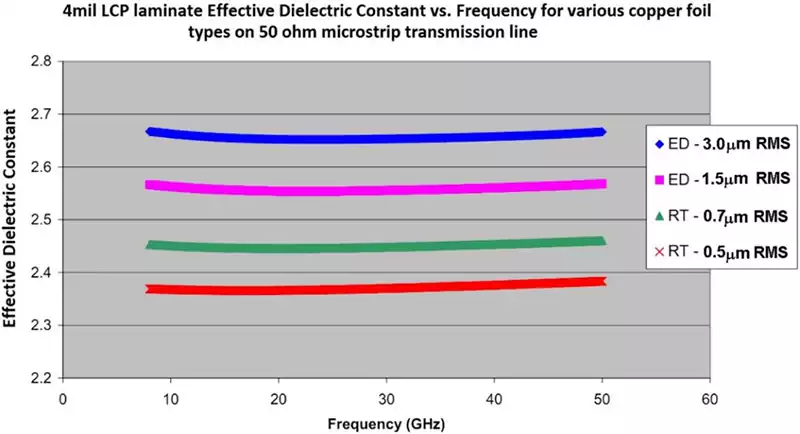

High speed PCB design specifically refers to systems that utilise high speed digital signals to transmit data between components. The boundary between high-speed digital design and simpler circuit boards employing slower digital protocols is not always clear cut.Typically,the key indicator determining whether a system qualifies as ‘high-speed’ is the edge rate (or rise time) of […]