Conformal coating, also known as triple-proof coating, is a functional polymer coating material specifically developed for printed circuit boards (PCBs). Its core function is to form a dense protective film that closely conforms to the contours of the PCB surface and component gaps, achieving the ‘triple protection’ effect of moisture, dust and corrosion resistance. It also provides auxiliary protective functions such as electrical insulation, temperature and vibration resistance, and mould prevention, thereby significantly enhancing the reliability and service life of the PCB board.

Unlike conventional physical protective casings, the greatest advantage of conformal coating lies in its ‘seamless encapsulation’. It neither impedes the PCB’s heat dissipation nor signal transmission while effectively shielding against various environmental threats. For PCB boards, moisture causes copper foil corrosion and component pin oxidation; dust accumulation may trigger circuit short-circuits; while corrosive gases in chemical environments accelerate substrate ageing. Conformal coating serves as the ‘first line of defence’ against these hazards, enabling stable PCB operation in non-ideal conditions such as outdoor environments, high temperatures and humidity, and industrial corrosion.

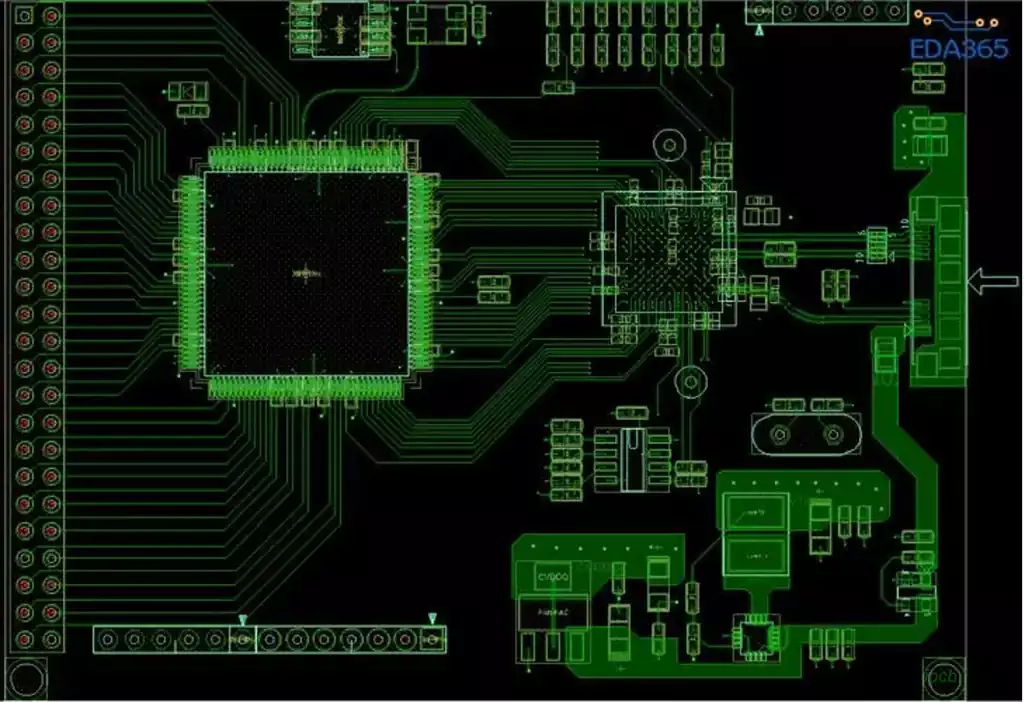

Core Requirements for Conformal Coating on PCB

1.Targeted Protection: PCB boards in different applications face distinct environmental threats. For instance, outdoor equipment PCBs require enhanced moisture and UV resistance, industrial control PCBs prioritise chemical corrosion protection, while automotive electronics PCBs must balance high/low temperature endurance with vibration resistance. This necessitates precise matching between coating processes and materials.

2.Production Adaptability: The coating process must align with PCB manufacturing volume requirements, accommodating both high-efficiency automated production for large batches and customised coating for small-batch, precision PCBs, balancing efficiency and precision;

3.Cost Control: While ensuring protective efficacy, optimise the coating process to minimise material waste and reduce rework rates, achieving a balance between quality and cost. This is also key to enhancing profitability in the PCB manufacturing sector.

Core Types and Applications of Conformal Coatings

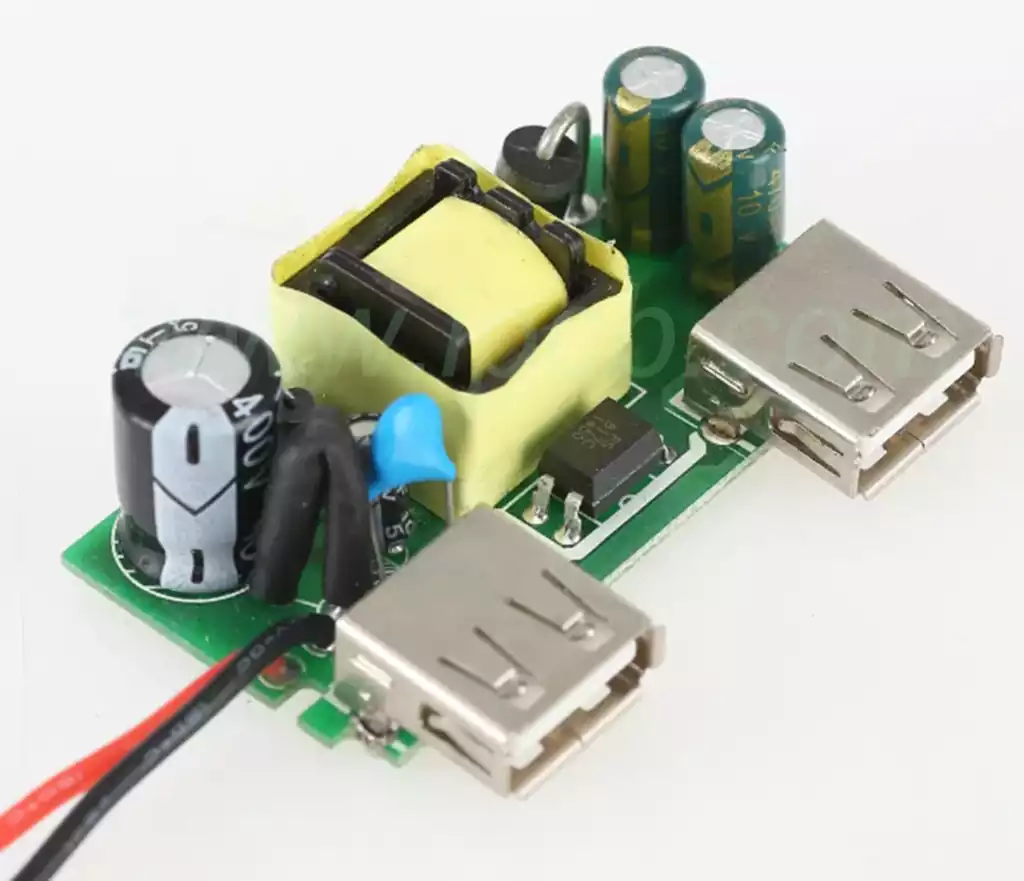

Acrylic resin-based conformal coatings offer excellent dielectric properties and rapid drying characteristics. They present low application difficulty and moderate cost, with easy solvent-based stripping for subsequent maintenance. Suitable for spray or brush application, they cater to mass-produced consumer electronics PCBs and prototype PCB production. However, their limited chemical and temperature resistance renders them unsuitable for harsh industrial environments.

Polyurethane conformal coatings excel in moisture/heat resistance and chemical tolerance, offering superior flexibility to withstand temperature fluctuations and mechanical vibration. Suitable for spraying or dip coating, they are commonly used in automotive electronics and outdoor equipment PCBs. Their drawback is the difficulty in removal post-curing, making them unsuitable for products requiring frequent rework.

Epoxy conformal coatings exhibit high hardness, chemical corrosion resistance, and exceptional moisture protection, withstanding high-temperature environments. Suitable for dip coating and dispensing processes, they are compatible with industrial control and military electronics PCBs. However, their brittle nature makes them unsuitable for severe vibration and extremely difficult to remove.

Silicone-based conformal coatings demonstrate outstanding high and low temperature resistance, with a long-term temperature tolerance spanning -60°C to 200°C. They offer good elasticity and strong moisture resistance, suitable for spray or dispensing application. Primarily used in automotive electronics and aerospace PCBs, their drawbacks include higher cost and susceptibility to dust adhesion.

Parylene conformal coatings are formed via vapour deposition, resulting in pinhole-free, ultra-thin, and highly uniform layers that achieve complete coverage without dead zones. They are suitable for precision medical electronics and micro-sensor PCBs. However, the coating equipment requires significant investment and is costly, making it applicable only for high-value products with zero-fault tolerance.

The Complete Process of Applying PCB Conformal Coating

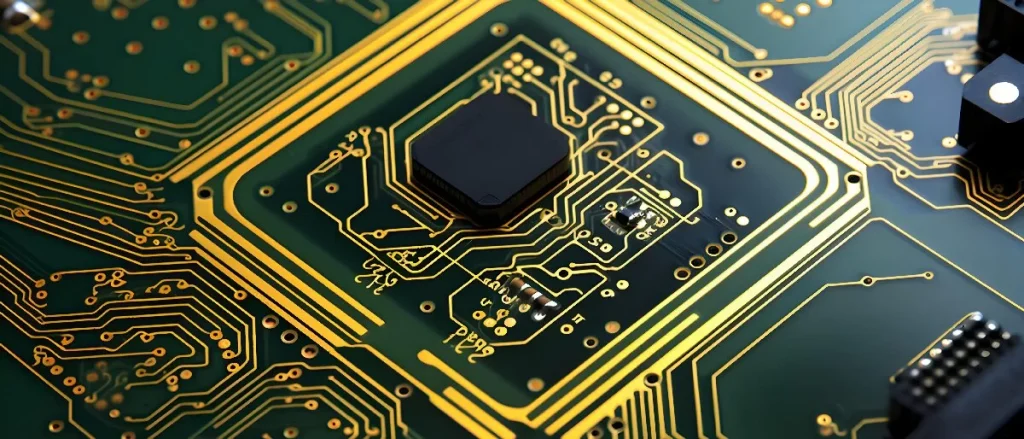

1.Key Pre-Treatment Processes for PCB Substrates Prior to Coating

Pre-treatment forms the foundational stage for conformal coating application and is critical in determining coating adhesion. Its core objective is the thorough removal of contaminants from the PCB surface to prevent defects such as coating delamination, pinholes, or delamination caused by oil residues, dust, or flux residues. The pass rate of pre-treatment directly dictates the yield of subsequent coating processes. Pre-treatment comprises two stages: cleaning and drying, adhering to the principle of ‘thorough cleaning and complete drying’ – there are no shortcuts.

The cleaning stage requires selecting appropriate methods based on PCB contamination types:

- Conventional oil stains and fingerprints may be removed using isopropyl alcohol or specialised PCB cleaning agents via wiping or ultrasonic cleaning.

- Stubborn flux residues necessitate ultrasonic cleaning, with cycle times controlled between 5-10 minutes. Military-grade or medical-grade PCBs may undergo plasma cleaning for micron-level surface purification. Avoid highly corrosive cleaning agents during this process to prevent damage to the PCB substrate and components.

The drying stage must ensure no moisture residue remains on the PCB surface. Two drying methods are available for cleaned PCBs: standard PCBs may be oven-dried at 60°C for 10-20 minutes or dried using compressed air; high-precision PCBs require oven-drying at 80°C for 30 minutes or ambient drying in an environment with humidity <30% for 24 hours. Post-drying PCBs must undergo immediate coating to prevent re-absorption of airborne dust and moisture. Should storage exceed two hours, re-cleaning and drying are required.

2.Precise Control of Process Parameters During Coating

The coating process is central to process optimisation. While parameter control varies across different coating techniques, all must adhere to the principle of ‘uniform coating, thin multiple layers, no missed areas or accumulation’. Core parameter control encompasses film thickness, coating speed, and paint flow rate: – Film thickness must be precisely controlled according to application requirements, avoiding excessive thickness or thinness. – Coating speed must be uniform and stable to prevent paint accumulation or missed coverage. – Paint flow rate must match coating speed to ensure continuous coating without breaks.

For automated coating processes (automatic spraying, selective coating), optimal parameters must be determined through process debugging. Initial sample inspection is required to verify coating uniformity, film thickness, and coverage before proceeding to batch production. During production, random sampling inspections must be conducted every hour to promptly adjust parameter deviations caused by changes in paint viscosity or equipment wear. For manual coating processes (brush application, hand spraying), standardised operating manuals must be established and operators professionally trained to minimise process fluctuations caused by human error.

Common defects in conformal coating application and targeted solutions

Pinholes: Microscopic pores appearing on the coating surface, primarily caused by excessive spray pressure, overly thick paint film, or moisture/dust on the PCB surface. Solutions include adjusting spray pressure to 0.2-0.4MPa, employing a thin-layer multi-coat process, thoroughly cleaning and drying the PCB, and allowing 3-5 minutes for levelling before curing.

Bubbles: Air pockets forming within or on the coating surface. For solvent-based paints, this occurs when curing temperatures are excessively high or paint viscosity is too thick, preventing solvent evaporation. For UV-curable paints, air ingress during application is the cause. Solutions include optimising oven temperature profiles, reducing paint viscosity, employing diaphragm pumps to prevent air entrainment, and thoroughly deaerating stirred paint.

Haze: A milky, foggy appearance on the coating surface. Caused by excessive ambient humidity (>80% RH) leading to moisture condensation. Solutions include maintaining humidity below 75%. Affected coatings may be baked at 60°C for 2 hours; severely affected areas should be removed and recoated.

Delamination / Peeling: Separation of coating from PCB substrate. Caused by surface contaminants or paint-substrate incompatibility. Solutions: Reclean PCB surface, replace with substrate-compatible conformal coating, apply primer before coating to enhance adhesion.

Sagging / Piling: Localised coating thickness leads to sagging, caused by low paint viscosity or excessively slow application speed. Solutions include increasing paint viscosity, accelerating application/lifting speed, adopting a thin-layer multi-coat process, and avoiding excessive thickness in a single application.

Technical Development Trends in PCB Conformal Coating Application Processes

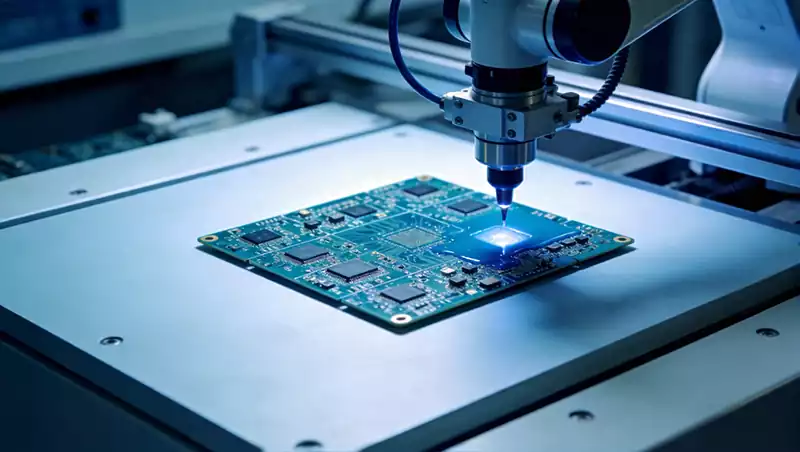

With the advancement of industries such as 5G, new energy vehicles, and the Internet of Things, PCB manufacturing is upgrading towards higher precision, density, and reliability. Concurrently, green manufacturing policies impose increasingly stringent environmental requirements. The conformal coating application process for PCB conformal coatings is undergoing a technological transformation from ‘traditional manual operation’ towards ‘intelligent, environmentally friendly, and customisable’ solutions. This evolution centres on triple upgrades in materials, equipment, and processes, achieving dual enhancements in protective efficacy and production efficiency.

Intelligent automation represents the core developmental trajectory for conformal coating application. Traditional manual coating will progressively be supplanted by automated, intelligent equipment, substantially enhancing both process precision and production efficiency. Currently, selective coating systems integrating AI vision with robotic arms have become the industry standard. These utilise AI algorithms to identify PCB board types and component locations in real-time, automatically planning coating paths while dynamically adjusting resin flow and application speed. This achieves coating thickness control within ±5μm. Simultaneously, intelligent equipment can interface with MES/ERP systems to enable digital traceability of the coating process. Combined with big data analytics to optimise process parameters, this facilitates ‘adaptive coating’.

Looking ahead, intelligent coating processes will evolve towards unmanned production lines. This will encompass the entire workflow—from PCB feeding, pre-treatment, coating, curing to inspection—achieving full automation. This approach reduces manual intervention, further enhances process stability and production efficiency, and meets the demands of high-volume mass production for high-precision PCBs.

Through meticulous process design, the conformal coating application for PCB protective coatings ensures high compatibility with the end-use scenarios of PCBs, thereby guaranteeing reliability throughout the entire lifecycle of electronic products.