Etching, is a key part of the printed circuit board manufacturing process. Simply put, etching is the process of chemically or physically removing unwanted metal parts from a circuit board to obtain the desired circuit pattern. This process has a critical impact on the accuracy and performance of the circuit board.

Technology of Etching Process

The etching process mainly utilizes a chemical solution to react chemically with the metal surface to form the desired pattern and shape on the metal surface. Etching process is mainly categorized into the following types:

Acid etching: Acid etching utilizes an acidic solution to react chemically with the metal surface, thereby forming the desired patterns and shapes on the metal surface. Acid etching has the advantages of high speed and high efficiency.

Alkaline etching: Alkaline etching is the use of alkaline solution and metal surface chemical reaction, so as to form the desired pattern and shape on the metal surface. Alkaline etching has less impact on the environment, but is slower and less efficient.

Electrolytic etching: Electrolytic etching is the use of electric current through the electrolyte solution and the metal surface electrochemical reaction,so as to form the desired pattern and shape on the metal surface. Electrolytic etching has the advantages of high precision and high efficiency,but at the same time, it also requires specialized equipment and higher energy consumption.

Application of Etching Process

Etching process is widely used in the production process of all kinds of metal products, such as stainless steel, aluminum, copper and so on. Through the etching process, metal products can present a unique texture and aesthetics, improve the added value of the product and market competitiveness.

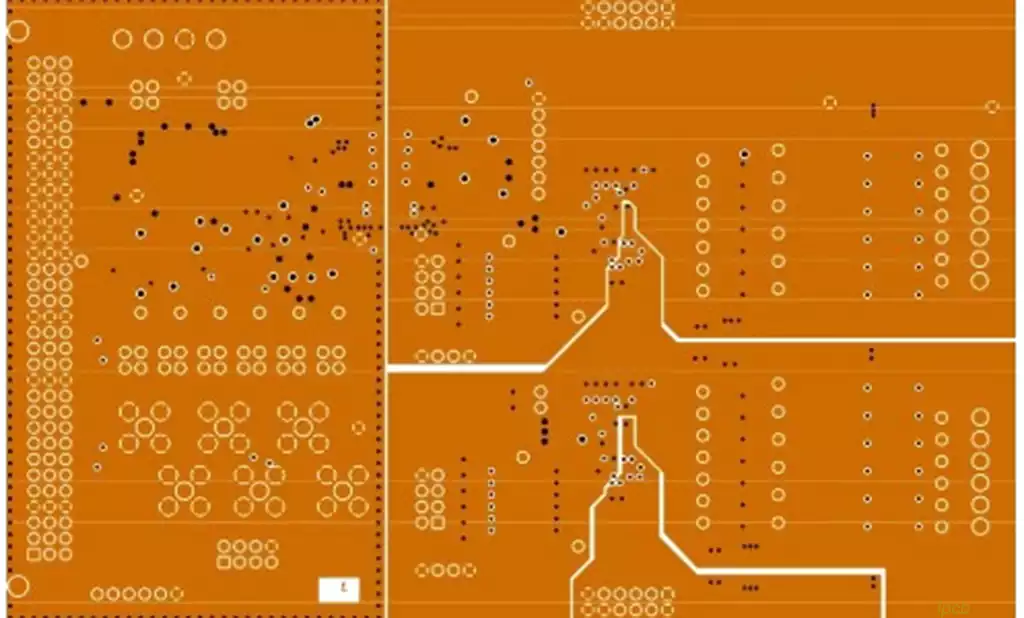

Before etching, the surface of the circuit board will be covered with a layer of photoresist. This layer of photoresist will form a pattern corresponding to the desired circuit pattern after exposure and development. The circuit board then enters an etching machine where it reacts with an etching solution. The chemicals in the etching solution react with the metal parts that are not protected by the photoresist to dissolve them away. This process requires precise control of time, temperature, and concentration of the etchant to ensure that only the unwanted metal parts are removed without causing damage to the rest of the board.

Once the etching is complete, the board is washed and dried to remove any residual photoresist and etchant. Eventually, a printed circuit board is born, which carries the mission of connecting and supporting electronic components, providing a solid foundation for the normal operation of electronic equipment.

Etching process considerations

Uniformity of lines

PCB prototyping circuit boards generally need to go through etching operations. For example, the full-plate copper-plating process needs to be etched off the photographic film outside the part, but in the etching operation must also maintain the uniformity of the line, while the board surface of each place should be plated twice copper, but also need to etch off the periphery of the panel, so as to maintain the line and the panel’s uniformity and reliability.

Suitable etchant

The vast majority of PCB multilayer circuit boards in the etching operation, are based on sulfate etching solution, in which the copper is separated by electrolysis. PCB multilayer circuit boards in the etching process, in which the copper is generally separated by electrolysis, only the right corrosive agent can be reused, so etching operations must be to choose the right corrosive agent.

Etching speed

PCB multilayer circuit board etching process also requires reasonable control of the corrosion rate of the corrosive agent. Today’s market commonly used corrosive agent is water/ammonia chloride etching solution, in the use of reasonable corrosion rate is also needed, because the corrosion rate is too fast may lead to the PCB board board are experiencing corrosion, while the corrosion rate is too slow may lead to poor corrosion of its board.

Although the printed circuit board etching is only a part of the electronic equipment manufacturing process, but it carries a vital mission. It is through this fine process, we can get stable performance, powerful electronic devices for our lives to bring more convenience and fun.