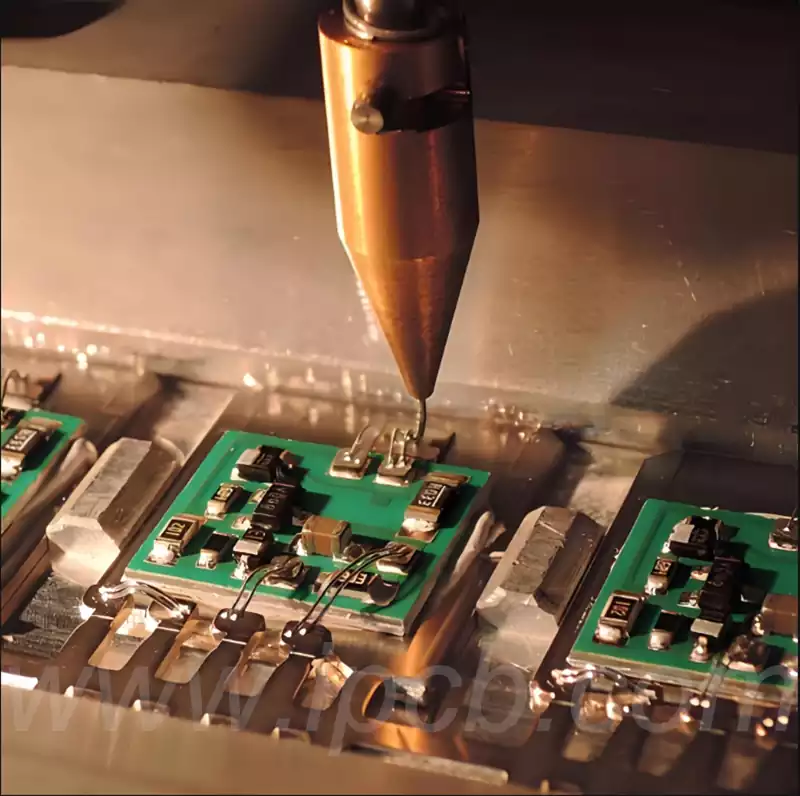

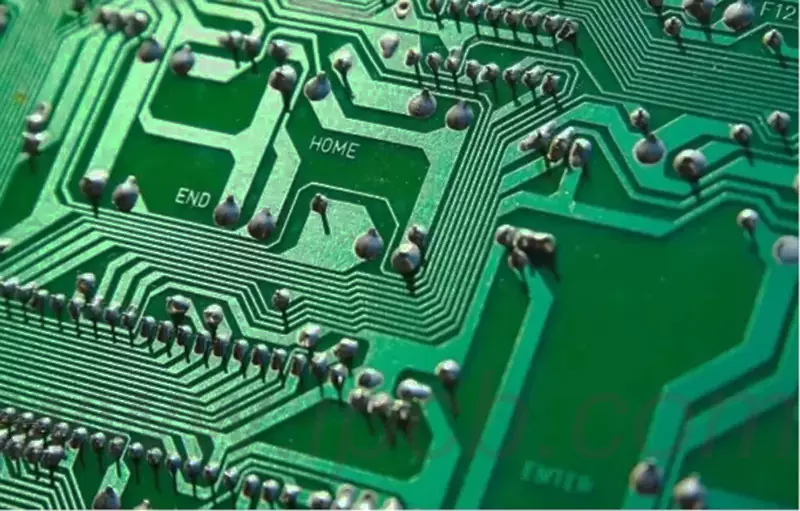

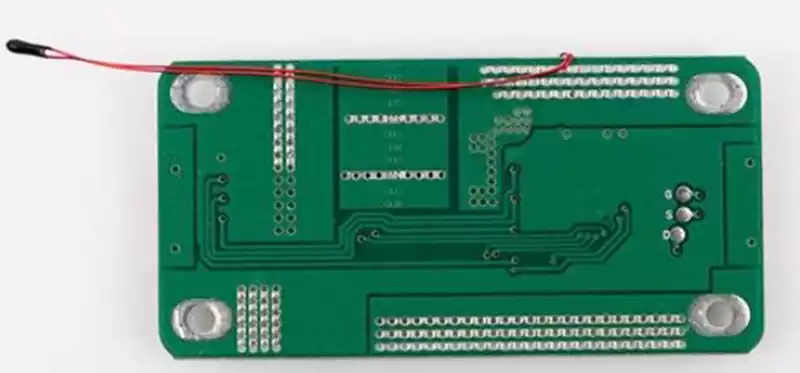

What to cut pcb with nipper

PCB cutting is a common operation in electronics manufacturing. While specialised equipment such as laser cutters and shears can provide highly accurate cuts, what to cut pcb with nipper is still a practical and cost-effective option in some cases. Common types of nipperDiagonal Nose nipper: Diagonal nose pliers are the most commonly used cutting tool […]