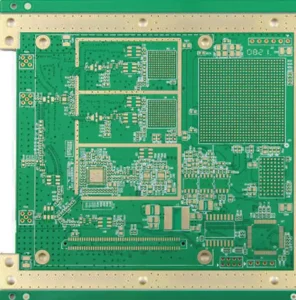

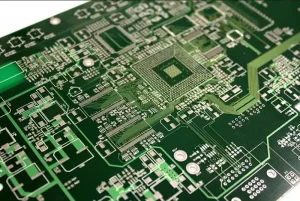

Preventing reference plane gap hazards in 4 layer PCB Boards

In a 4 layer PCB board, although signal crossing over reference plane gaps may seem minor, it can trigger a series of issues such as signal distortion, electromagnetic interference (EMI),

Key Considerations for Differential Wiring Switching in 4 layer pcb

When routing differential wiring on 4 layer pcbs, inadvertent interlayer transitions can readily cause signal distortion and a sharp decline in product yield. Unlike single-layer or thick multilayer boards, the

Breaking Through with Ultra-Fine Circuit Design on HDI Boards

In the context of the PCB manufacturing industry’s upgrade towards high-end and miniaturization, HDI boards, with their unique technological architecture, have become the core carrier for solving the challenges of

Causes and Remedies for PCB Pad Detachment

The PCB pad, as a critical part connecting components to the PCB, directly determines the performance and stability of the entire circuit. However, in actual production and maintenance processes, pad

PCB Conformal Coating Application Process

Conformal coating, also known as triple-proof coating, is a functional polymer coating material specifically developed for printed circuit boards (PCBs). Its core function is to form a dense protective film

Inner Layer Black Oxide Process for PCBs

The inner layer black oxide process is one of the earliest surface treatment technologies applied in multilayer PCB manufacturing. With mature technology and relatively low cost, it is still widely

Impedance Boards and Production Tolerance Control

Impedance Boards (commonly referred to as impedance boards) are specialized circuit boards in PCB manufacturing that require precise design, calculation, and strict production control of signal trace characteristic impedance. Their

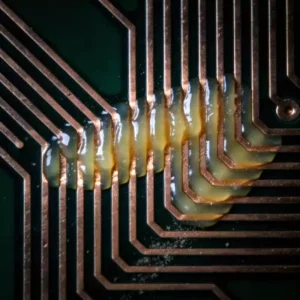

Analysing the Hazards of Flux Residue on PCB

In PCB soldering processes, the role of flux is indispensable. Without high-quality flux, even with premium solder and precision equipment, achieving acceptable solder joints remains challenging. Yet flux exhibits a

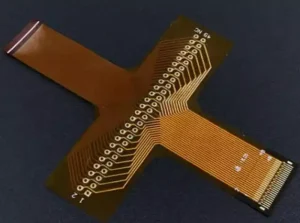

Key Considerations for Material Selection and Routing Design in FPC Design

FPC has gained increasing application in the trend towards miniaturisation and portability of electronic devices, owing to their unique flexibility. However, FPC design is complex and specialised, involving multiple critical

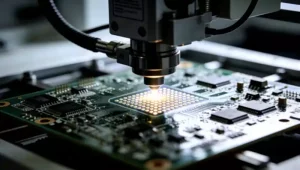

PCB Board Soldering Machine: Ensuring Consistent and Reliable Assembly

The Core Role of PCB Board Soldering Machines in Electronics Manufacturing In the electronics manufacturing process, PCB board soldering machines are one of the key links determining product reliability and

Optimising control loop area within the inner layers of 4 layer board

PCB loop area refers to the physical spatial area enclosed by the closed circuit formed by current flow on a printed circuit board (PCB). It is a critical factor influencing

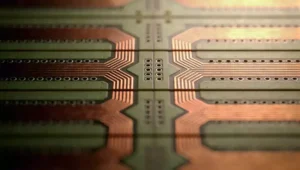

The Impact of 4 Layer Board Via Parasitic Parameters on Signals and Optimisation Strategies

In 4 layer board designs (typical stack-ups such as signal layer-ground layer-power layer-signal layer), vias serve as the core carriers for interlayer interconnections, facilitating signal, power, and ground continuity between

Causes and Hazards of Warpage in 4 Layer PCBs

In actual production and usage, warping issues in 4 layer PCBs are frequently encountered. This not only impacts production yield and assembly efficiency but also poses long-term reliability risks for

The role of the core board and prepreg in a 4-layer PCB

4-layer PCBs find extensive application across numerous sectors including consumer electronics, industrial control systems, and automotive electronics. Their pivotal role owes much to the core materials—the core board and prepreg.

Moisture Resistance of FR4 PCBs

The moisture resistance of FR4 PCBs is directly linked to the stability and longevity of electronic products. Material selection, process optimization, and strict environmental control are all indispensable. Only through

Reflow Soldering Temperature Profile for Ceramic Circuit Boards

Ceramic circuit boards, owing to their high-temperature resistance and superior thermal conductivity, have progressively become the preferred substrate for high-power electronic components. However, their inherent ceramic properties pose significant challenges

Why Prototype SMT Assembly Determines Manufacturing Success

The Core Value and Industry Positioning of Prototype SMT Assembly In today’s world of increasingly compressed electronic product development cycles, Prototype SMT Assembly is no longer just a simple step

Aluminium nitride ceramic circuit boards empower laser diode applications

Behind the faint light pulses of laser diodes lies an uncompromising demand for substrate material. From the precise detection of autonomous driving lidar to the high-speed transmission of 800G optical

Thermal Conductivity Properties and Development Trends of Ceramic Circuit Boards

When the thermal conductivity of conventional FR-4 substrates, typically below 1 W/(m·K), proves inadequate for managing the thermal loads of high-power devices, ceramic circuit boards emerge as the preferred solution.

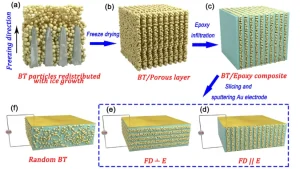

Analysis of high dielectric constant

In the wave of nanotechnology, two-dimensional materials have become a focus in the field of materials science due to their atomic scale thickness and unique physical properties. Among them, High-k

PCB Circuit Board Connection Methods

Connections between pcb circuit boards are primarily achieved through conductive connectors, wires, flexible printed circuits (FPC), board-to-board connectors, and soldering techniques. Among these, flexible printed circuits (FPC) serve as a

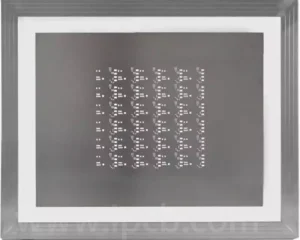

The Role and Classification of SMT Stencils in Surface Mount Technology

SMT stencils, commonly referred to as ‘templates’, are an indispensable component of the SMT (Surface Mount Technology) process; they serve as the template for printing solder paste onto the PCB

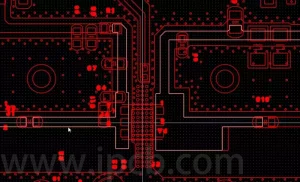

Factors Affecting PCB Trace Impedance and Calculation Methods

PCB trace impedance refers to the total resistance encountered by electrical signals during transmission across a PCB board. In layman’s terms, it represents the ‘resistance’ encountered by electrical signals as

Characteristics and Applications of Semi Flex PCB

Semi flex pcb is essentially “standard” multilayer PCBs manufactured using specific grades of FR4. The thickness of the FR4 is subject to particular tolerances, enabling thinner sections to provide the