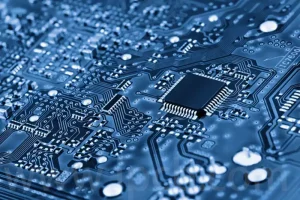

Special Rogers HDI PCB Board Design and Applications

Introduction and Background Amid the rapid development of today’s high-speed digital and radio frequency electronics industries, circuit board materials and structural design are becoming crucial for corporate competitiveness. While traditional

Principles and Applications of Microwave Radio Frequency Technology

Microwave radio frequency technology refers to techniques utilising radio waves within the frequency range of 300MHz to 300GHz for information transmission, processing, or application. Radio frequency (RF) typically denotes electromagnetic

Characteristics and Applications of Microwave RF PCB

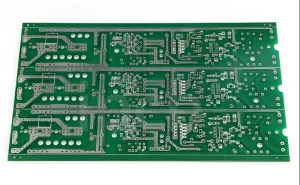

Microwave RF PCB refers to microwave components manufactured using conventional rigid PCB fabrication methods on specific microwave-grade copper-clad laminates. In printed circuit board wiring for high-speed signal transmission lines, products

PCB Design and Material Selection for 4D Millimeter-Wave Radar

4D millimeter-wave radar represents an upgrade from conventional millimetre-wave radar, with “4D” denoting four dimensions: velocity, distance, horizontal angle, and vertical height. Compared to conventional 3D millimeter-wave radar, 4D millimetre-wave

Milling PCB Board Precision Processing and Applications

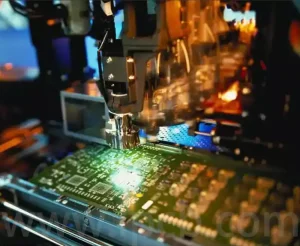

Introduction and Clarification In the electronics manufacturing industry, printed circuit boards (PCBs) are fabricated using a variety of methods. Milling, as a key process, is gaining increasing attention from companies

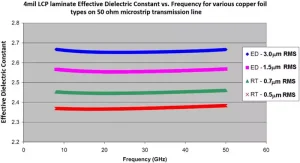

Key Performance Characteristics of PCB Materials for 77GHz Automotive Radar

The significance of high-frequency PCB materials in 77 GHz automotive radar applications. Within the high-frequency spectrum, although numerous novel PCB materials have been developed, not all are suitable for such

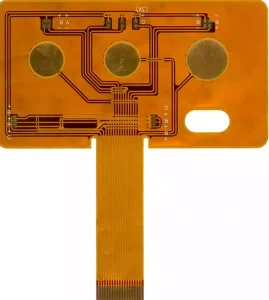

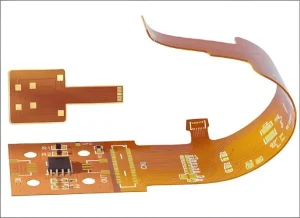

Differences in Layout and Routing for Single- and Double-Sided Flexible Printed Circuit Boards

Flexible printed circuit boards (FPCs), serving as core components for interconnecting electronic devices, have their layer count design directly impacting product performance, cost, and application scenarios. Based on the number

Features and Advantages of Flexible LED Strip Lights

Flexible LED strip lights, also known as flexible ribbon lights, utilise FPC as the substrate circuit board and are assembled with surface-mount LEDs, resulting in a product thickness of merely

High Frequency PCB Design and Manufacturing Challenges and Solutions

With the rapid proliferation of electronic products and the swift advancement of technology, demand for high-frequency, high-speed printed circuit boards continues to grow. High frequency PCB plays a pivotal role

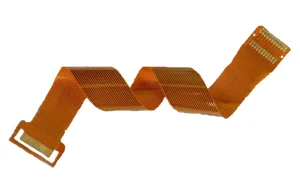

Manufacturing Techniques And Challenges For Multilayer Flex PCB

Multilayer flex pcb is formed by laminating three or more layers of single-sided or double-sided flexible circuit boards together. Through-holes are created via drilling and plating, establishing conductive pathways between

Applications and Technical Challenges of Flexible PCB Assembly

Flexible PCB assembly refers to circuit boards manufactured using flexible substrates, offering superior bendability and adaptability compared to traditional rigid PCBs. Flexible PCB assembly enables higher-density routing, saving space and

The Application of Photoresist in Electronics Manufacturing

Photoresist, also known as photo-resistive material, refers to an etch-resistant thin-film material whose solubility changes upon exposure to ultraviolet light, electron beams, ion beams, X-rays, or other forms of radiation.

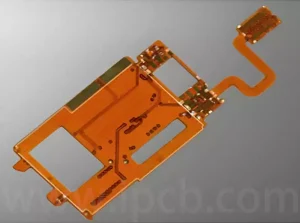

Flex PCB Prototype Design Verification and Future Directions

Overview and Basic Concepts of Flex PCB Prototypes In modern electronics design and manufacturing, flex PCB prototypes (flexible printed circuit board prototypes) have become an essential component of innovative product

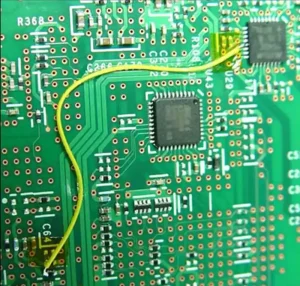

Key Considerations for Fabricating PCB Jumper

PCB jumper refers to spaces reserved on a printed circuit board for connecting circuits, achieved by adding conductive wires and connectors. They serve a broad purpose in circuit design, effectively

Distinction between Lead-Free and Leaded Hot Air Reflow Processes for PCB Circuit Boards

The surface treatment process of PCB circuit boards is crucial to their performance and environmental credentials. Among these, the tin-plating process is widely favoured for its cost-effectiveness and solderability. Tin-plating

What are leaded and leadfree processes?

What are leaded and leadfree processes? Leaded solder typically consists primarily of tin-lead (Sn-Pb) alloys, such as the classic Sn63/Pb37 (63% tin, 37% lead), which has a low melting point

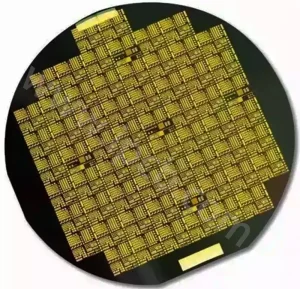

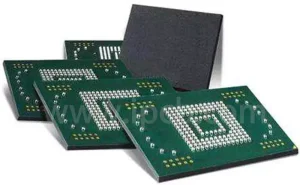

Semiconductor encapsulation process and development

The encapsulation process, also known as the packaging process, involves the secure enclosure of semiconductor chips using specific materials. This provides effective defence against environmental degradation, ensuring stable chip operation.

PCB Board Transformer Fundamentals and Practical Applications

Definition and Function of a PCB Board Transformer In modern electronics manufacturing, the term “PCB board transformer” is a common yet often misunderstood concept. It typically refers to a transformer

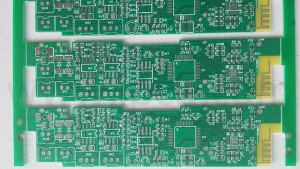

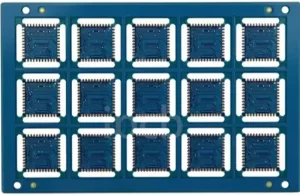

Differences Between Multilayer and Double-Layer PCB Board

As electronic products demand increasingly diverse functionalities, pcb board structures have grown ever more complex. Constrained by spatial limitations, PCB circuit boards have progressively “evolved” from single-layer to double-layer and

Ionic cleanliness Testing Methods and Importance for PCB Boards

Ionic cleanliness testing serves as a critical quality control measure for evaluating ionic contaminant levels on pcb boards surfaces. Its primary objective is to prevent electrical faults such as short

Characteristics and Applications of FR1 PCB

FR1 pcb is constructed from glass fiber-reinforced epoxy resin laminates. FR1 PCBs are rigid, flat materials composed of thin copper layers on a non-conductive phenolic resin substrate. FR1, fully known

Application and Advantages of PCB Laser Depaneling Technology

In electronic manufacturing, circuit boards must be divided into distinct sections to meet the design requirements of various electronic products. Traditional mechanical cutting and punching techniques struggle to satisfy modern

OSP process ensures stable PCB performance

OSP (Organic Solderability Preservative) is a surface treatment process for PCBs (Printed Circuit Boards). It involves coating the copper foil surface with an extremely thin organic protective film (approximately 0.2-0.5μm

Methods and Significance of PCB Board Ion Cleanliness Testing

Ion cleanliness typically refers to the ion cleanliness of pcb board. Residual ions from various materials during the cleaning process can compromise the functionality and reliability of electronic products. Common