Advantages and influencing factors of electroplating hole filling process

Electroplating via filling is a key technology in the field of modern high-density electronic packaging. It not only greatly enhances the design flexibility and performance of PCB boards, but also

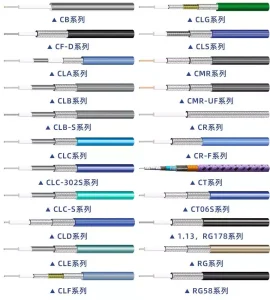

Performance testing and transmission distance of RF cable assembly

RF cable assembly is cable that transmit radio frequency (RF) signals from one device to another. They consist of coaxial cable and RF connectors at both ends. Coaxial cable has

What is a RF cable?

What is a RF cable? A RF cable is a type of cable used for transmitting high-frequency signals, and its construction differs from that of ordinary cables. RF cable typically

Key Techniques for RF Circuit Board Design Interference Resistance

As a core component of electronic devices, the performance stability of RF circuit boards directly affects the overall operational effectiveness of the device. However, in complex electromagnetic environments, RF circuit

RF PCB Shielding Methods

RF pcbs are core components in electronic devices, and their performance stability directly affects the overall operational effectiveness of the device. However, in complex electromagnetic environments, RF circuit boards are

Application and advantages of dry film solder mask in PCB manufacturing

IntroductionAs electronic devices increasingly move toward higher density, higher performance, and smaller form factors, the manufacturing requirements for printed circuit boards (PCBs) are also increasing. As the foundation of electronic

The Function and Design Points of PCB Teardrop

What is a PCB teardrop? A PCB teardrop is an additional copper pad, either straight or circular, located at the connection point between a pad or via and a trace,

Sputtering target materials contribute to the development of EMI coating

EMI coating is a thin film made from materials that shield electromagnetic interference signals, capable of blocking the propagation of electromagnetic waves. EMI coating is typically made from conductive materials

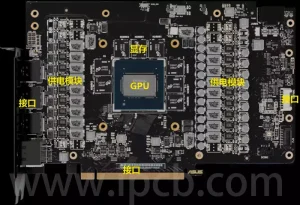

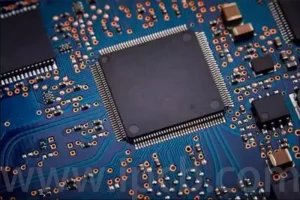

The impact of graphics card pcb layer count on performance

A graphics card circuit board, also known as a graphics card motherboard or graphics card PCB, is a circuit board used to transmit signals from the graphics processing unit (GPU).

The core role of the graphics card PCB power supply system

On a graphics card pcb, the power supply section is just as critical as the graphics processing unit (GPU). If the GPU is the ‘brain’ of the graphics card, then

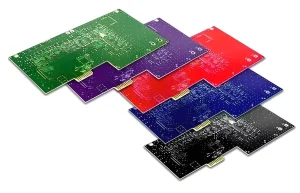

Exploring the Future of Solder Mask Material in PCB Design

Definition and Function of Solder Mask Material in PCB Design In the printed circuit board (PCB) manufacturing process, solder mask is a crucial protective coating. It’s typically green, hence the

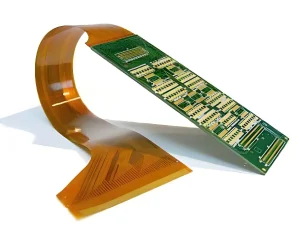

Advantages and disadvantages of FPC coverlay

What is coverlay in fpc?FPC coverlay is polymer film made from materials such as polyimide (PI), primarily used to protect and insulate the external circuits of flexible PCB. FPC coverlay

Introduction to PCB overmolding process

PCB overmolding is a technique that involves coating printed circuit boards (PCBs) with protective polymer resin. This process is designed to protect PCBs from external factors such as humidity, dirt,

Causes and Countermeasures for PCB Warping in SMT Processing

PCB warping is a common quality issue in surface mount technology (SMT) processing, severely affecting the performance and reliability of electronic products. This phenomenon is not caused by a single

Strategies for dealing with solder contamination on PCB gold fingers

In the field of electronic product manufacturing, solder contamination on PCB gold fingers is a common and challenging issue that significantly impacts product performance and reliability. Especially during critical processes

Challenges in the production of microwave pcb

The production process for high-frequency microwave pcb is complex and requires extremely high precision, encompassing multiple critical stages from engineering data processing to final forming. To ensure product quality and

Exploring the Value of HDI Flex PCB in Electronic Design and Manufacturing

Definition and Development Background of HDI Flexible Circuit Boards Driven by the trend toward increasingly thinner, smaller, and highly integrated electronic products, traditional rigid circuit boards are no longer able

Features of microwave pcb manufacturing

The manufacturing of microwave pcb has multiple distinctive features, primarily manifested in the diversity of substrate materials, stringent requirements for design precision, computer-controlled manufacturing processes, specialised graphic production, diverse surface

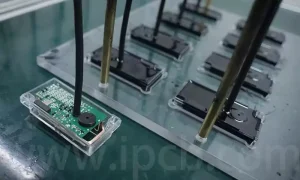

PCBA Test Fixture Principles and Manufacturing Process

PCBA test fixtures, also known as ‘test fixtures, play a crucial role in the PCBA manufacturing process. They are primarily used to conduct comprehensive testing on PCBs that have undergone

Classification and Selection of RF Connectors

RF connectors are electrical connectors used for transmitting radio frequency signals. They are also referred to as coaxial connectors within the industry, as RF connectors are typically connected to coaxial

Some Factors Affecting the Performance of Microstrip Patch Antennas

Microstrip patch antennas and their arrays may not be seen much but are the most widely used form of antenna. They are simple in structure and can be formed by

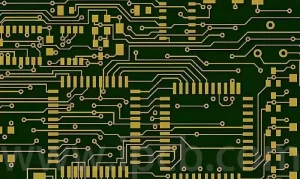

High Frequency PCB Materials and Selection

High frequency pcb is special circuit board dedicated to higher electromagnetic frequencies, applicable to high-frequency (frequency over 300MHz and wavelength less than 1 metre) and microwave (frequency higher than 3GHz,

High-Tg PCB and Selection

What is a high-Tg PCB? What are the advantages of using high Tg PCBs? When the temperature of a high Tg printed circuit board rises to a certain range, the

What is 94v-0 on a pcb?

What is 94v-0 on a pcb? The 94v-0 standard is a standard set for the combustion characteristics of plastic materials in electronic and electrical products. It was established by Underwriters