PCB prepreg is a soft material, similar to the black tape, also called ‘semi-glue’ or ‘film’, commonly used in the production of circuit boards. In the PCB PP is sandwiched between the core board and copper foil or two core boards before the dielectric layer to play an insulating role. It is made of polymer material. It is made of polymer materials, its main component is silicone rubber. Hydrogenated silicone rubber, etc., has a very good resistance to high temperature. Corrosion resistance.

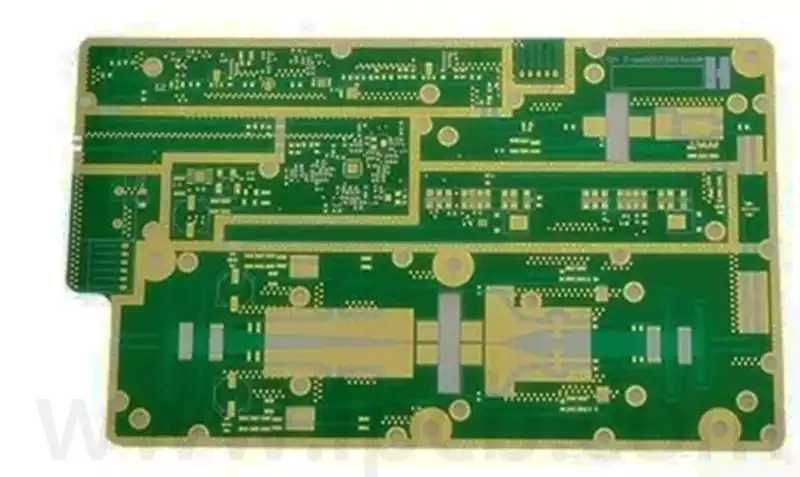

PP semi-cured sheet, also known as pcb prepreg material, impregnated with resin and cured to an intermediate degree (B order) of sheet material. It is mainly used as the adhesive material and insulating material for the inner conductive pattern of multilayer printed boards. After Prepreg is laminated, the semi-cured epoxy resin is squeezed out, starts to flow and solidifies, bonding the multilayer boards together and forming a layer of reliable insulator.PCB industry Simply put, prepreg semi-cured sheet is equivalent to the role of glue, using prepreg to link several cores into a multilayer board by lamination (lamination). The resin impregnated on the adhesive sheet is only the resin that is impregnated.

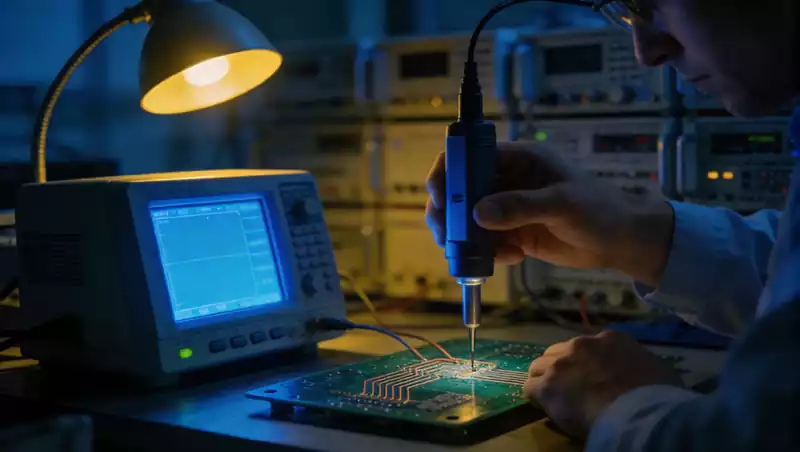

The impregnated resin on the film is only solid but not fully cured, in the pressing process, the core board, pcb prepreg and copper foil in accordance with the design of the stacked structure for stacking, at this time, PP film in the role of heat and pressure, the impregnated resin on the PP began to bond the adjacent layers. After cross-linking and slow curing, the material properties of the pressed PCB begin to approach those of the core board.

PCB prepreg is a polymer material consisting of Glass Fabric, Resin, Curing Agent, Accelerator, Solvent and Additive. Simply put, PP is mainly formed by the glass fibre cloth infiltrated in the resin, after a series of process reaction.

Glass Fiber Cloth: referred to as Glass Fiber Cloth or Glass Cloth, is made of woven glass fibre Glass Fiber. Glass fibre cloth has two weaving directions: the horizontal direction is generally referred to as the ‘weft’ and the vertical direction is generally referred to as the ‘warp’. Depending on the type of semi-cured sheet, the type and tightness of the glass fibre cloth is different. The gap and uniformity of the glass fibre cloth inside the PCB affects the signal transmission and is often referred to as the glass fibre effect.

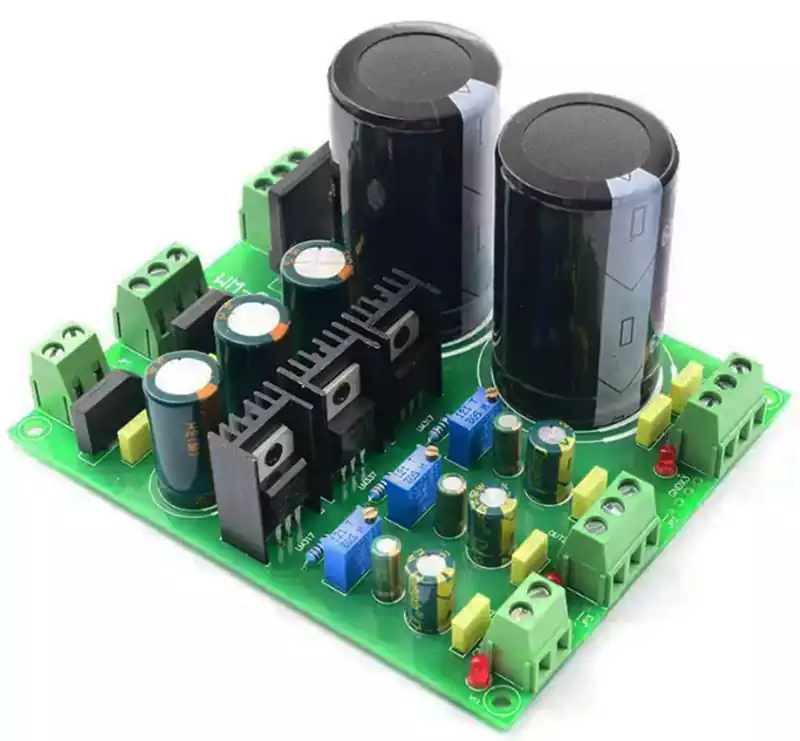

Core: A core board is a rigid material with a specific thickness and a copper double-coated surface.

The difference between pcb prepreg and core:

- Prepreg in the PCB belongs to a material, the former material semi-solid, similar to cardboard, the latter material is hard, similar to copper;

- Prepreg is similar to adhesives + insulator; and Core is the basis of the PCB material, the two are completely different functions;

- Prepreg can be curled and Core can not be bent;

- Prepreg is not conductive, and Core has a copper layer on both sides, is the conductive medium of the printed circuit board.

PCB prepreg materials in the thickness of the requirements are very diverse to meet the needs of various applications. Common standard thicknesses cover a wide range of specifications such as 0.5mm, 1mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm and 20mm, which are suitable for most conventional applications.

In addition to these conventional thicknesses, pcb prepreg can also be customised according to customers’ special needs, whether thinner or thicker specifications can be achieved by adjusting the manufacturing process, which fully reflects its high degree of flexibility and adapts to more professional and special use environments.

In terms of dimensional specifications, pcb prepreg is availables in a wide range of widths, commonly 1000mm, 1200mm, 1220mm, 1500mm, etc., to meet the dimensional requirements of different equipment and containers. The length is usually customised according to customer requirements, generally ranging from 100mm to 10,000mm, and common recommended sizes include 1500×3000mm, 1220×2440mm and 1000×2000mm, which are not only convenient for production, but also for transportation and installation.

The choice of thickness of pcb prepreg is closely related to the specific application. For example, in acid and alkali resistance, electroplating, and waste water and exhaust gas discharge equipment, thicker PP sheets are usually used to ensure the strength and safety of the equipment; while in areas where lightweight is important, such as aerospace, thinner sheets are often chosen to reduce the overall weight.

In addition, the thickness of a pcb prepreg material has a direct impact on its physical properties and processing characteristics. Thicker sheets usually show better rigidity and strength, while thinner sheets have better bending properties and are easier to mould, meeting the diverse needs of different processing and product design.

The use of pcb prepreg in multilayer PCB structures has the following advantages:

- Ensure the reliability of interlayer insulation to meet high-frequency signal transmission requirements

- Maintain the structural integrity of the circuit board, resistance to mechanical stress damage

- Adapt to complex wiring design, support for high-density component layout

PCB prepreg as an important dielectric material in the manufacture of multi-layer PCB, its unique physical and chemical properties of the overall performance of the circuit board plays a crucial role in ensuring. With the development of electronic products towards high-speed, high-density and complexity, the value of semi-cured sheet in support of advanced PCB design and manufacturing process will become more and more prominent. Reasonable selection and application of prepregs has become a key step in improving PCB quality and reliability, laying a solid foundation for the technological progress of the electronics industry.