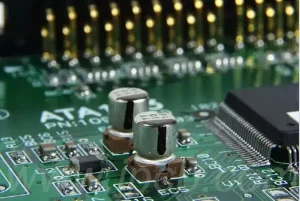

Anti-jamming design of RF circuit board

Radio frequency circuit board plays a vital role in modern communication systems, especially in applications such as wireless communications,radar systems and medical devices. However, RF signals are susceptible to various

Functions and Applications of LED Control Board

LED control board is a kind of electronic circuit board used to control light-emitting diodes (LEDs). Its main function is to control the brightness, colour and flashing mode of LEDs

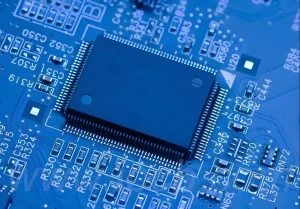

Differences between radio frequency circuit board and ordinary PCB

In the construction of electronic devices, circuit boards are indispensable basic components, which are responsible for connecting electronic components and realising signal transmission and processing. Among the many types of

Application of x-ray machine for pcb

The x-ray machine for pcb is a non-destructive inspection device for printed circuit boards using the X-ray transmission principle. With the help of X-ray imaging, it is able to accurately

what tool to cut keyboard pcb

what tool to cut keyboard pcb? First of all, cutting boards is a must for many reasons. One common reason is that some of the projects you are working on

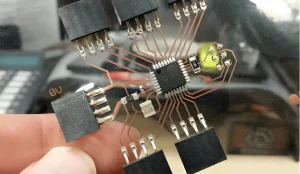

Leaded Wire Bonding Technology Applications

Wire bonding is a method of connecting metal leads to pads, i.e., it is a technique for connecting internal and external chips. Structurally, the metal leads act as a bridge

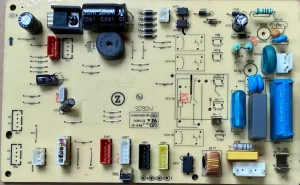

Circuit board on ac unit function and troubleshooting

The circuit board on ac unit is a key component that ensures the efficient operation of the system. It acts as the central nervous system, controlling and coordinating the various

PCB Manufacturing Quality Challenges

PCB manufacturing is a complex and delicate process that involves numerous matching points,and the slightest mishap can lead to defects in the board, which in turn affects the quality of

The melting point of lead

Lead is a chemical element with an atomic number of 82 and an atomic weight of 207.2 u. Lead is a heavy metal that is denser than most common materials.

Board Edge Connector Design Essentials

The board edge connector is an important electronic component that plays an indispensable role in modern electronic equipment. Its main function is to provide electrical connection and signal transmission, usually

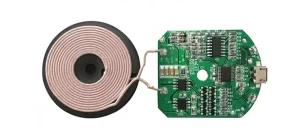

Wireless charger pcb applications

Wireless charger pcb, as the name suggests, is a circuit board used for wireless charging of mobile phones. It adopts advanced wireless charging technology, which transmits electricity to the mobile

Application Prospects of Transparent PCB Boards

Transparent PCB board refers to a printed circuit board (PCB) manufactured using transparent materials as a substrate. It not only has the circuit conduction and connection functions of traditional PCB,

Microphone PCB design elements

Microphone PCB is a key component of audio equipment, mainly used to support the microphone’s electronic components and circuit connections. A microphone is a device that converts sound signals into

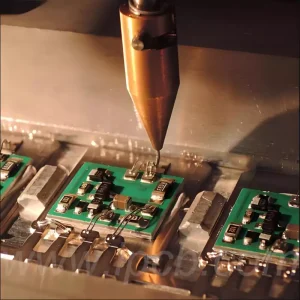

Selective Soldering Technology

Selective soldering is a soldering technique used to connect electronic components to circuit boards, primarily to achieve precise solder joints, often in complex circuit designs. This method of soldering is

Thermal conductivity of aluminum and its applications

Aluminum is a common metal element with many excellent properties such as light weight, corrosion resistance, and easy processing. Therefore, it is widely used in aerospace, transportation, construction, electronics and

Flip Chip vs Wire Bonding Technology

Flip Chip Bonding is a highly efficient semiconductor packaging method widely used in high performance electronic devices. This technique achieves compact package design and excellent electrical performance by inverting the

The Function and Application of PCB Terminal Strip

PCB terminal strip refers to the connection terminals on the PCB board, usually used to connect to other circuits or devices. It is connected to other electronic components through various

Breadboard vs PCB is circuit dual tools

In the field of electronic engineering technology, breadboard vs pcb is two widely used tools in different stages of circuit design and development. Breadboards serve as a recyclable platform for

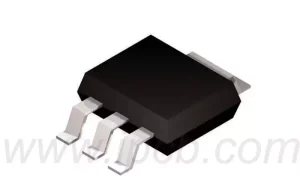

Transistor Surface Mount Technology

Transistor surface mount, also known as chip transistors, are developed from conventional plug-in transistors, which have the same core, only the package is different, and most of them follow the

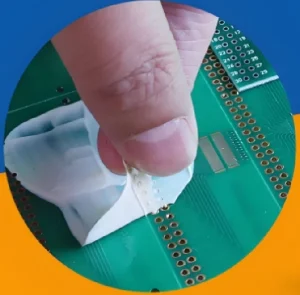

Advantages and Applications of Peelable Solder Mask

In the manufacturing of modern electronic equipment, printed circuit boards (PCBs) play a vital role as the basic platform for connecting and supporting various electronic components. The soldering process of

Key Role of PCB Bus Bar

The PCB Bus Bar is one of the key components of a printed circuit board (PCB) and is primarily responsible for the transmission of current on the board. It is

screw terminal pcb

Screw terminal pcb refers to a component similar to an inductor that is made by directly drawing a coil on the pcb board with traces. Because this process has the

High Current PCB Design Essentials

High Current PCB is circuit board designed specifically for the needs of high current applications. Compared to standard boards,they are characterised by thicker layers of copper, wider wires and excellent

Enhance PCB board current carrying capacity

PCB board is often designed for small-current applications, so what can be done to enhance PCB boards to withstand larger currents? After all, the current demand of the electronic products